What is Global High Frequency Copper Clad Laminate (CCL) Market?

The Global High Frequency Copper Clad Laminate (CCL) Market is a specialized segment within the broader electronics materials industry, focusing on the production and distribution of copper-clad laminates designed to operate at high frequencies. These laminates are essential components in the manufacturing of printed circuit boards (PCBs), which are used in a wide range of electronic devices. High frequency CCLs are specifically engineered to handle the demands of high-speed and high-frequency electronic applications, making them crucial for modern communication systems, automotive electronics, and advanced computing technologies. The market for these materials is driven by the increasing demand for faster and more efficient electronic devices, as well as the ongoing advancements in telecommunications infrastructure, such as the rollout of 5G networks. As technology continues to evolve, the need for high-performance materials like high frequency CCLs is expected to grow, supporting the development of next-generation electronic devices and systems. The market is characterized by a focus on innovation and quality, with manufacturers striving to produce laminates that offer superior electrical performance, thermal management, and reliability. This market is a key enabler of technological progress, underpinning the capabilities of modern electronic systems.

PTFE CCL, Hydrocarbon Resin-Based Composite CCL, Others in the Global High Frequency Copper Clad Laminate (CCL) Market:

PTFE CCL, Hydrocarbon Resin-Based Composite CCL, and other types of high frequency copper clad laminates each play distinct roles in the Global High Frequency Copper Clad Laminate (CCL) Market, catering to various applications and performance requirements. PTFE CCL, or polytetrafluoroethylene copper clad laminate, is renowned for its excellent dielectric properties, low dissipation factor, and high thermal stability. These characteristics make PTFE CCLs ideal for high-frequency applications where signal integrity and minimal signal loss are critical. PTFE CCLs are often used in microwave and RF applications, including radar systems, satellite communications, and high-speed data transmission. The material's inherent resistance to moisture and chemicals further enhances its suitability for demanding environments, ensuring reliable performance over extended periods. Hydrocarbon Resin-Based Composite CCLs, on the other hand, offer a different set of advantages. These laminates are typically composed of a blend of hydrocarbon resins and other reinforcing materials, providing a balance between performance and cost-effectiveness. Hydrocarbon Resin-Based CCLs are known for their good electrical properties, mechanical strength, and ease of processing. They are often used in applications where cost considerations are important, but where high-frequency performance is still required. These laminates are commonly found in telecommunications equipment, automotive radar systems, and other electronic devices that operate at high frequencies but do not require the extreme performance characteristics of PTFE CCLs. In addition to PTFE and Hydrocarbon Resin-Based CCLs, the market also includes other types of high frequency copper clad laminates, each designed to meet specific application needs. These may include laminates based on ceramic-filled materials, which offer excellent thermal management and dimensional stability, making them suitable for high-power applications. Other laminates may be designed to provide enhanced flexibility, allowing for use in flexible circuits and wearable electronics. The diversity of materials and formulations available in the market reflects the wide range of applications and performance requirements that high frequency CCLs must meet. The choice of laminate type depends on several factors, including the specific frequency range, environmental conditions, mechanical requirements, and cost constraints of the application. Manufacturers in the Global High Frequency Copper Clad Laminate (CCL) Market are continually innovating to develop new materials and improve existing ones, ensuring that they can meet the evolving needs of the electronics industry. This ongoing innovation is driven by the increasing complexity and performance demands of modern electronic devices, as well as the need for materials that can support the next generation of technologies, such as 5G, IoT, and advanced automotive systems. Overall, the Global High Frequency Copper Clad Laminate (CCL) Market is characterized by a diverse range of materials and technologies, each offering unique benefits and addressing specific application requirements. Whether it's the superior dielectric properties of PTFE CCLs, the cost-effectiveness of Hydrocarbon Resin-Based CCLs, or the specialized capabilities of other laminate types, the market provides a wide array of options for manufacturers and designers of high-frequency electronic systems. As the demand for high-performance electronic devices continues to grow, the importance of high frequency CCLs in enabling these technologies cannot be overstated.

Antenna System, Communication System, In-vehicle/Infotainment System, Others in the Global High Frequency Copper Clad Laminate (CCL) Market:

The usage of Global High Frequency Copper Clad Laminate (CCL) Market materials spans several critical areas, including antenna systems, communication systems, in-vehicle/infotainment systems, and other applications. In antenna systems, high frequency CCLs are essential for ensuring efficient signal transmission and reception. These laminates provide the necessary electrical properties to maintain signal integrity and minimize losses, which is crucial for applications such as satellite communications, radar systems, and wireless networks. The ability of high frequency CCLs to operate effectively at microwave and millimeter-wave frequencies makes them indispensable in the design and manufacture of advanced antenna systems. In communication systems, high frequency CCLs play a vital role in supporting the infrastructure required for modern telecommunications. As the demand for faster and more reliable communication networks grows, so does the need for materials that can handle high data rates and frequencies. High frequency CCLs are used in the production of printed circuit boards for base stations, routers, and other networking equipment, where they help to ensure optimal performance and reliability. The rollout of 5G networks, in particular, has driven increased demand for high frequency CCLs, as these networks operate at higher frequencies and require materials that can support their advanced capabilities. In-vehicle and infotainment systems also benefit from the use of high frequency CCLs. As automotive technology advances, vehicles are increasingly equipped with sophisticated electronic systems that require high-performance materials. High frequency CCLs are used in automotive radar systems, which are essential for advanced driver-assistance systems (ADAS) and autonomous driving technologies. These laminates provide the necessary electrical and thermal properties to ensure reliable operation in the challenging automotive environment. Additionally, high frequency CCLs are used in infotainment systems, where they support high-speed data transmission and connectivity features that enhance the driving experience. Beyond these specific applications, high frequency CCLs are used in a variety of other areas, including aerospace, defense, and industrial electronics. In aerospace and defense, these laminates are used in the production of high-performance radar and communication systems, where their ability to operate at high frequencies and withstand harsh conditions is critical. In industrial electronics, high frequency CCLs are used in applications such as high-speed data acquisition and processing, where their superior electrical properties contribute to improved system performance. Overall, the Global High Frequency Copper Clad Laminate (CCL) Market plays a crucial role in enabling the development and deployment of advanced electronic systems across a wide range of industries. The unique properties of high frequency CCLs make them indispensable in applications where performance, reliability, and efficiency are paramount. As technology continues to evolve, the demand for these materials is expected to grow, supporting the ongoing advancement of communication, automotive, and other electronic systems.

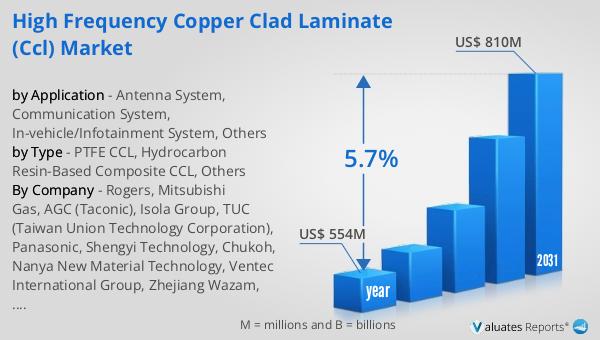

Global High Frequency Copper Clad Laminate (CCL) Market Outlook:

The global market for High Frequency Copper Clad Laminate (CCL) was valued at $554 million in 2024 and is anticipated to expand to a revised size of $810 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.7% over the forecast period. This growth trajectory underscores the increasing demand for high-performance materials in the electronics industry, driven by advancements in telecommunications, automotive electronics, and other high-frequency applications. The market is characterized by a high level of concentration, with the top five players collectively holding a market share exceeding 80%. This concentration indicates a competitive landscape where leading companies leverage their technological expertise, production capabilities, and strategic partnerships to maintain their market positions. These companies are at the forefront of innovation, continually developing new materials and improving existing ones to meet the evolving needs of the industry. As the demand for high frequency CCLs continues to rise, these market leaders are well-positioned to capitalize on emerging opportunities and drive further growth in the market. The outlook for the Global High Frequency Copper Clad Laminate (CCL) Market is positive, with ongoing technological advancements and increasing demand for high-performance electronic materials expected to support continued expansion.

| Report Metric | Details |

| Report Name | High Frequency Copper Clad Laminate (CCL) Market |

| Accounted market size in year | US$ 554 million |

| Forecasted market size in 2031 | US$ 810 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Rogers, Mitsubishi Gas, AGC (Taconic), Isola Group, TUC (Taiwan Union Technology Corporation), Panasonic, Shengyi Technology, Chukoh, Nanya New Material Technology, Ventec International Group, Zhejiang Wazam, Zhuhai Guoneng, Taizhou Wangling Insulation Materials Factory, Wuxi Relong New Material Technology, Jiu Yao Electronic Science & Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |