What is Global Extrusion Press Equipment Market?

The Global Extrusion Press Equipment Market is a dynamic and essential segment of the manufacturing industry, focusing on machinery that shapes materials by forcing them through a die. This process, known as extrusion, is crucial for creating a wide range of products with specific cross-sectional profiles. The market encompasses various types of extrusion press equipment, each designed to handle different materials such as metals, plastics, and composites. These machines are integral to industries like automotive, construction, aerospace, and consumer goods, where precision and efficiency in material shaping are paramount. The market's growth is driven by technological advancements, increasing demand for lightweight and durable materials, and the need for efficient manufacturing processes. As industries continue to innovate and expand, the Global Extrusion Press Equipment Market is poised to play a critical role in supporting these developments by providing the necessary tools for high-quality production. The market's evolution reflects broader trends in industrial automation and the pursuit of sustainable manufacturing practices, making it a key area of interest for stakeholders across various sectors.

Aluminium Extrusion Press, Copper Extrusion Press, Other in the Global Extrusion Press Equipment Market:

Aluminium extrusion presses are a significant component of the Global Extrusion Press Equipment Market, primarily due to the widespread use of aluminium in various industries. Aluminium's lightweight, corrosion-resistant, and recyclable properties make it an ideal material for applications in automotive, aerospace, and construction sectors. The extrusion process involves heating aluminium billets and forcing them through a die to create profiles with specific shapes and sizes. This method allows for the production of complex cross-sections that are both strong and lightweight, essential for reducing vehicle weight and improving fuel efficiency in the automotive industry. In construction, aluminium extrusions are used for window frames, curtain walls, and structural components, offering durability and aesthetic appeal. The demand for aluminium extrusion presses is driven by the need for energy-efficient and sustainable building materials, as well as the growing emphasis on lightweight components in transportation. Copper extrusion presses, on the other hand, cater to industries where electrical conductivity and thermal properties are paramount. Copper is a preferred material for electrical wiring, plumbing, and heat exchangers due to its excellent conductivity and resistance to corrosion. The extrusion process for copper involves similar principles as aluminium, where copper billets are heated and pressed through a die to form rods, bars, and tubes. These extruded products are crucial for the electrical and electronics industries, where precision and reliability are essential. The demand for copper extrusion presses is influenced by the growth in renewable energy projects, electric vehicles, and infrastructure development, all of which require efficient electrical systems and components. Beyond aluminium and copper, the Global Extrusion Press Equipment Market also includes presses for other materials such as plastics, composites, and specialty metals. Plastic extrusion presses are vital for producing pipes, profiles, and films used in packaging, construction, and consumer goods. The versatility of plastic extrusion allows for the creation of products with varying thicknesses, textures, and colors, catering to diverse market needs. Composite extrusion presses are gaining traction as industries seek materials that combine the best properties of different substances, such as strength, flexibility, and resistance to environmental factors. These presses are used to produce components for aerospace, automotive, and sports equipment, where performance and weight are critical considerations. Specialty metal extrusion presses handle materials like titanium, magnesium, and nickel alloys, which are used in high-performance applications requiring exceptional strength and resistance to extreme conditions. The demand for these presses is driven by advancements in aerospace, defense, and medical industries, where cutting-edge materials are essential for innovation and safety. The Global Extrusion Press Equipment Market is characterized by continuous innovation and adaptation to meet the evolving needs of various industries. Manufacturers are investing in research and development to enhance the efficiency, precision, and sustainability of extrusion processes. This includes the integration of automation, digitalization, and advanced control systems to optimize production and reduce waste. As industries face increasing pressure to minimize their environmental impact, the market is also focusing on developing energy-efficient and eco-friendly extrusion solutions. The shift towards circular economy principles, where materials are reused and recycled, further underscores the importance of extrusion technology in achieving sustainable manufacturing practices. Overall, the Global Extrusion Press Equipment Market is a vital enabler of industrial progress, providing the tools necessary for shaping the future of manufacturing across diverse sectors.

Transportation, Construction, Machinery, Other in the Global Extrusion Press Equipment Market:

The Global Extrusion Press Equipment Market finds extensive usage across various sectors, with transportation being one of the most significant. In the automotive industry, extrusion presses are used to produce lightweight components that enhance fuel efficiency and reduce emissions. Aluminium extrusions, for instance, are employed in manufacturing vehicle frames, engine blocks, and body panels, contributing to the overall reduction in vehicle weight. This not only improves fuel economy but also aligns with stringent environmental regulations aimed at reducing carbon footprints. In the aerospace sector, extrusion presses are crucial for producing structural components that require high strength-to-weight ratios. The ability to create complex shapes with precision makes extrusion technology indispensable for manufacturing aircraft parts that meet rigorous safety and performance standards. In the construction industry, extrusion presses play a pivotal role in producing materials that are both functional and aesthetically pleasing. Aluminium extrusions are widely used for window frames, curtain walls, and roofing systems, offering durability, corrosion resistance, and design flexibility. The construction sector's growing emphasis on sustainable building practices has further increased the demand for extruded products that contribute to energy efficiency and reduced environmental impact. Extrusion technology also enables the production of composite materials that combine the best properties of different substances, such as strength, insulation, and fire resistance, making them ideal for modern construction applications. The machinery sector benefits from the Global Extrusion Press Equipment Market through the production of components that require high precision and durability. Extrusion presses are used to manufacture parts for industrial machinery, agricultural equipment, and heavy-duty vehicles, where reliability and performance are critical. The ability to produce custom profiles with tight tolerances ensures that machinery components meet specific operational requirements, enhancing overall efficiency and productivity. As industries continue to automate and modernize their operations, the demand for high-quality extruded components is expected to rise, driving further innovation in extrusion technology. Beyond these primary sectors, the Global Extrusion Press Equipment Market also serves a wide range of other industries, each with unique requirements and applications. In the consumer goods sector, extrusion presses are used to produce packaging materials, household items, and electronic components, where versatility and cost-effectiveness are key considerations. The medical industry relies on extrusion technology for manufacturing devices and components that require biocompatibility and precision, such as catheters, tubing, and implants. The renewable energy sector also benefits from extrusion presses, particularly in the production of components for solar panels, wind turbines, and energy storage systems. As the world shifts towards cleaner energy sources, the demand for extruded products that support sustainable energy solutions is expected to grow. Overall, the Global Extrusion Press Equipment Market is integral to a wide array of industries, providing the tools necessary for innovation and efficiency. The versatility of extrusion technology allows for the creation of products that meet specific performance criteria, enabling industries to adapt to changing market demands and regulatory requirements. As global trends continue to emphasize sustainability, efficiency, and technological advancement, the role of extrusion presses in shaping the future of manufacturing becomes increasingly significant.

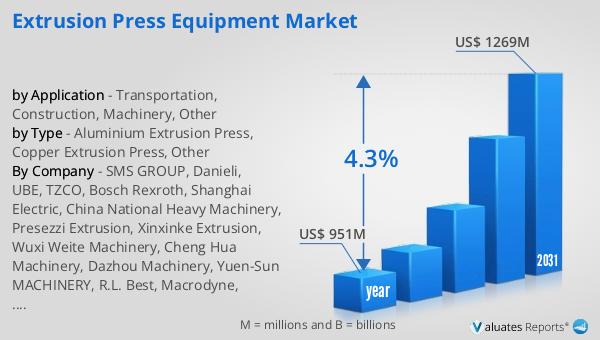

Global Extrusion Press Equipment Market Outlook:

In 2024, the global market for Extrusion Press Equipment was valued at approximately $951 million. Looking ahead, this market is anticipated to expand, reaching an estimated size of $1,269 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.3% over the forecast period. This upward trend is indicative of the increasing demand for extrusion press equipment across various industries, driven by the need for efficient and precise manufacturing processes. The market's expansion is supported by technological advancements that enhance the capabilities of extrusion presses, allowing for the production of complex and high-quality products. Additionally, the growing emphasis on sustainability and energy efficiency in manufacturing practices is expected to further fuel the demand for advanced extrusion press equipment. As industries continue to innovate and adapt to changing market dynamics, the Global Extrusion Press Equipment Market is poised to play a crucial role in supporting these developments. The projected growth underscores the importance of extrusion technology in meeting the evolving needs of industries worldwide, providing the tools necessary for high-quality production and sustainable manufacturing practices.

| Report Metric | Details |

| Report Name | Extrusion Press Equipment Market |

| Accounted market size in year | US$ 951 million |

| Forecasted market size in 2031 | US$ 1269 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SMS GROUP, Danieli, UBE, TZCO, Bosch Rexroth, Shanghai Electric, China National Heavy Machinery, Presezzi Extrusion, Xinxinke Extrusion, Wuxi Weite Machinery, Cheng Hua Machinery, Dazhou Machinery, Yuen-Sun MACHINERY, R.L. Best, Macrodyne, EXTRAL Technology, GIA Clecim Press, Wuxi Yimeide |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |