What is Global Glass Cutting Fluids Market?

The Global Glass Cutting Fluids Market is a specialized segment within the broader industrial fluids industry, focusing on the production and distribution of fluids used in the glass cutting process. These fluids are essential in ensuring precision, efficiency, and quality in cutting various types of glass, including optical and plate glass. The market is driven by the increasing demand for high-quality glass products in various industries such as automotive, construction, and electronics. Glass cutting fluids help in reducing friction, cooling the cutting tools, and preventing the glass from cracking or chipping during the cutting process. They also play a crucial role in extending the life of cutting tools and improving the overall efficiency of the glass cutting operations. The market is characterized by a diverse range of products, including pure oils, soluble oils, synthetic liquids, and semi-synthetic liquids, each offering unique benefits and applications. As industries continue to innovate and demand more precise and efficient glass cutting solutions, the Global Glass Cutting Fluids Market is expected to grow, driven by technological advancements and the increasing adoption of automated cutting processes.

Pure Oil, Soluble Oil, Synthetic Liquid, Semi-Synthetic Liquid in the Global Glass Cutting Fluids Market:

In the Global Glass Cutting Fluids Market, various types of fluids are used, each with distinct properties and applications. Pure oil-based fluids are traditional cutting fluids known for their excellent lubrication properties. They are particularly effective in heavy-duty cutting operations where high levels of lubrication are required to prevent tool wear and ensure smooth cutting. However, pure oils can be less effective in cooling, which can be a limitation in high-speed cutting operations. Soluble oils, on the other hand, are a mixture of oil and water, offering a balance between lubrication and cooling. They are versatile and widely used in various glass cutting applications due to their ability to provide adequate lubrication while also dissipating heat effectively. This makes them suitable for both light and heavy-duty cutting operations. Synthetic liquids are entirely water-based and contain no oil. They are designed to offer superior cooling properties, making them ideal for high-speed cutting operations where heat dissipation is critical. Synthetic fluids are also known for their cleanliness, as they do not leave oily residues on the glass or cutting tools. However, they may not provide the same level of lubrication as oil-based fluids, which can be a consideration in certain applications. Semi-synthetic liquids are a hybrid between soluble oils and synthetic fluids, containing both oil and synthetic components. They offer a compromise between lubrication and cooling, making them suitable for a wide range of cutting operations. Semi-synthetic fluids are often preferred for their versatility and ability to perform well in various cutting conditions. Each type of fluid has its advantages and limitations, and the choice of fluid often depends on the specific requirements of the cutting operation, such as the type of glass being cut, the speed of the operation, and the desired finish quality. As the Global Glass Cutting Fluids Market continues to evolve, manufacturers are focusing on developing advanced formulations that offer improved performance, environmental sustainability, and cost-effectiveness.

Optical Glass, Plate Glass in the Global Glass Cutting Fluids Market:

The usage of Global Glass Cutting Fluids Market in the areas of optical glass and plate glass is critical due to the specific requirements and challenges associated with cutting these types of glass. Optical glass, used in lenses, prisms, and other precision optical components, requires extremely precise cutting to maintain the optical clarity and accuracy of the finished product. Cutting fluids used in optical glass cutting must provide excellent lubrication to minimize friction and prevent chipping or cracking of the glass. They must also offer effective cooling to dissipate the heat generated during the cutting process, which can affect the optical properties of the glass. Additionally, the fluids must be clean and free of contaminants that could affect the optical quality of the glass. Plate glass, commonly used in windows, doors, and architectural applications, also requires precise cutting to ensure a smooth finish and prevent defects. The cutting fluids used in plate glass cutting must provide a balance between lubrication and cooling to ensure efficient cutting and extend the life of the cutting tools. They must also be compatible with the automated cutting equipment commonly used in plate glass manufacturing. In both optical and plate glass cutting, the choice of cutting fluid can significantly impact the quality and efficiency of the cutting process. Manufacturers in the Global Glass Cutting Fluids Market are continuously developing new formulations to meet the evolving needs of these industries, focusing on improving performance, reducing environmental impact, and enhancing cost-effectiveness. As the demand for high-quality optical and plate glass products continues to grow, the role of cutting fluids in ensuring precision and efficiency in the cutting process becomes increasingly important.

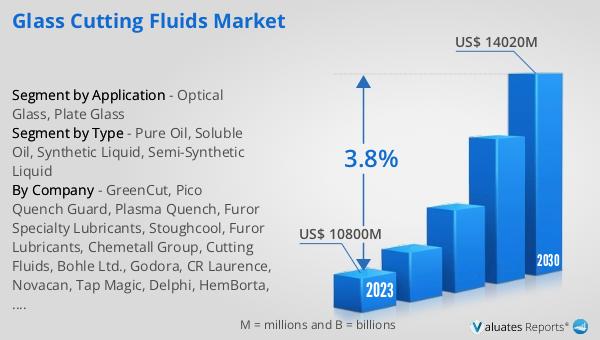

Global Glass Cutting Fluids Market Outlook:

The global market for Glass Cutting Fluids was valued at approximately $11.59 billion in 2024, with projections indicating that it will expand to a revised size of around $15 billion by 2031. This growth represents a compound annual growth rate (CAGR) of 3.8% over the forecast period. This steady growth is indicative of the increasing demand for glass cutting fluids across various industries, driven by the need for high-quality glass products and the adoption of advanced cutting technologies. The market's expansion is supported by the continuous innovation in fluid formulations, which aim to enhance cutting efficiency, tool life, and environmental sustainability. As industries such as automotive, construction, and electronics continue to grow, the demand for precision glass cutting solutions is expected to rise, further fueling the market's growth. The projected increase in market size reflects the importance of glass cutting fluids in ensuring the quality and efficiency of glass cutting operations, as well as the ongoing efforts by manufacturers to develop advanced products that meet the evolving needs of their customers. This growth trajectory underscores the critical role that glass cutting fluids play in the global manufacturing landscape, highlighting the need for continued investment in research and development to drive innovation and meet the challenges of an ever-changing market.

| Report Metric | Details |

| Report Name | Glass Cutting Fluids Market |

| Accounted market size in year | US$ 11590 million |

| Forecasted market size in 2031 | US$ 15000 million |

| CAGR | 3.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | GreenCut, Pico Quench Guard, Plasma Quench, Furor Specialty Lubricants, Stoughcool, Furor Lubricants, Chemetall Group, Cutting Fluids, Bohle Ltd., Godora, CR Laurence, Novacan, Tap Magic, Delphi, HemBorta, Creative Glass Guild, Impresa, EnviroGold, Inland Craft, CONDAT, Aquasol, KOG, Talamoni |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |