What is Global Glass-based Photomask Market?

The Global Glass-based Photomask Market is a crucial segment within the broader photomask industry, which plays a vital role in the manufacturing of semiconductors and various electronic components. Photomasks are essential tools used in photolithography, a process that involves transferring intricate patterns onto semiconductor wafers. These patterns are critical for creating the complex circuits found in electronic devices. Glass-based photomasks, in particular, are favored for their durability, precision, and ability to withstand the high temperatures and chemical processes involved in semiconductor manufacturing. The market for these photomasks is driven by the increasing demand for electronic devices, advancements in technology, and the miniaturization of semiconductor components. As industries such as consumer electronics, automotive, and telecommunications continue to grow, the need for high-quality photomasks becomes even more pronounced. This market is characterized by continuous innovation, with companies investing in research and development to enhance the performance and capabilities of glass-based photomasks. The global reach of this market is evident, with significant contributions from regions such as North America, Asia-Pacific, and Europe, each playing a pivotal role in the production and consumption of these essential components.

Synthetic Quartz Mask, Soda Lime Mask in the Global Glass-based Photomask Market:

In the realm of the Global Glass-based Photomask Market, two prominent types of masks are the Synthetic Quartz Mask and the Soda Lime Mask. Each of these masks serves specific purposes and offers distinct advantages, catering to different needs within the industry. Synthetic Quartz Masks are highly regarded for their exceptional optical clarity and thermal stability. These masks are made from high-purity quartz, which allows them to transmit ultraviolet (UV) light with minimal absorption. This property is crucial in photolithography processes that require precise patterning at very small scales, such as those used in advanced semiconductor manufacturing. The ability of synthetic quartz to withstand high temperatures without deforming makes it ideal for applications that involve intense heat, ensuring that the patterns remain accurate and consistent throughout the production process. Furthermore, the low thermal expansion coefficient of synthetic quartz minimizes the risk of distortion, maintaining the integrity of the photomask over repeated uses. On the other hand, Soda Lime Masks are more commonly used for less demanding applications. These masks are made from soda lime glass, which is more cost-effective compared to synthetic quartz. While they may not offer the same level of optical clarity or thermal stability, soda lime masks are suitable for applications where extreme precision is not as critical. They are often used in the production of larger electronic components or in processes where the photomask is not subjected to high temperatures. The affordability of soda lime masks makes them an attractive option for manufacturers looking to balance cost and performance. Despite their differences, both types of masks are integral to the photomask market, providing manufacturers with the flexibility to choose the right tool for their specific needs. As technology continues to evolve, the demand for both synthetic quartz and soda lime masks is expected to grow, driven by the increasing complexity of electronic devices and the need for more sophisticated manufacturing processes. Companies in the photomask industry are continually exploring new materials and techniques to enhance the performance of these masks, ensuring that they can meet the ever-changing demands of the market. The interplay between cost, performance, and application requirements will continue to shape the development and adoption of synthetic quartz and soda lime masks in the global glass-based photomask market.

Semiconductor, Flat Panel Display, Others in the Global Glass-based Photomask Market:

The Global Glass-based Photomask Market finds extensive usage across various sectors, with significant applications in the semiconductor industry, flat panel display manufacturing, and other areas. In the semiconductor industry, photomasks are indispensable tools used in the photolithography process, which is a critical step in the fabrication of integrated circuits. These circuits form the backbone of modern electronic devices, from smartphones and computers to automotive electronics and industrial machinery. The precision and accuracy of glass-based photomasks are essential for creating the intricate patterns required for semiconductor components, ensuring that they function correctly and efficiently. As the demand for smaller, more powerful, and energy-efficient electronic devices continues to rise, the role of photomasks in semiconductor manufacturing becomes even more crucial. In the flat panel display sector, glass-based photomasks are used to produce the intricate patterns needed for liquid crystal displays (LCDs), organic light-emitting diode (OLED) displays, and other advanced display technologies. These displays are ubiquitous in consumer electronics, including televisions, smartphones, tablets, and monitors. The quality and resolution of the photomask directly impact the performance and visual clarity of the final display product. As consumers increasingly seek high-definition and ultra-high-definition displays, manufacturers rely on advanced photomasks to meet these expectations. The ability of glass-based photomasks to deliver precise and consistent patterns is vital for producing displays with vibrant colors, sharp images, and fast refresh rates. Beyond semiconductors and flat panel displays, glass-based photomasks are also used in other industries, such as micro-electromechanical systems (MEMS), photonic devices, and printed circuit boards (PCBs). In MEMS manufacturing, photomasks are used to create the micro-scale structures that enable the functionality of sensors, actuators, and other miniature devices. Photonic devices, which are essential for optical communication systems, also rely on photomasks to define the intricate waveguide patterns that guide light signals. In the production of PCBs, photomasks are used to etch the circuit patterns onto the board, ensuring that the electrical connections are accurate and reliable. The versatility and precision of glass-based photomasks make them indispensable across these diverse applications, highlighting their importance in the modern technological landscape. As industries continue to innovate and push the boundaries of what is possible, the demand for high-quality photomasks is expected to grow, driving further advancements in the Global Glass-based Photomask Market.

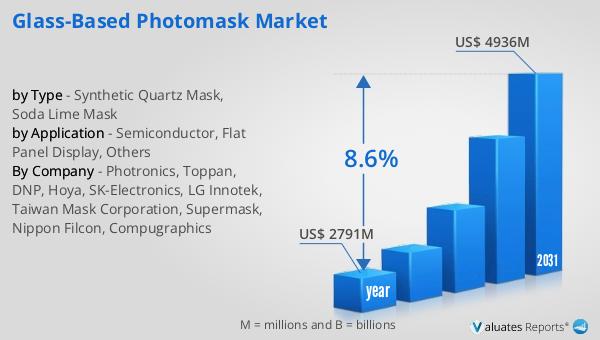

Global Glass-based Photomask Market Outlook:

The outlook for the Global Glass-based Photomask Market is promising, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately US$ 2,791 million, reflecting the strong demand for photomasks across various industries. This demand is driven by the continuous advancements in technology and the increasing complexity of electronic devices, which require precise and reliable photomasks for their production. Looking ahead, the market is projected to expand significantly, reaching an estimated size of US$ 4,936 million by 2031. This growth represents a compound annual growth rate (CAGR) of 8.6% during the forecast period, underscoring the robust potential of the market. Several factors contribute to this positive outlook, including the rising demand for semiconductors, the proliferation of consumer electronics, and the ongoing development of new display technologies. As industries continue to evolve and innovate, the need for high-quality photomasks will remain a critical component of the manufacturing process. Companies operating in the Global Glass-based Photomask Market are likely to invest in research and development to enhance the performance and capabilities of their products, ensuring that they can meet the ever-changing demands of the market. This focus on innovation, coupled with the growing demand for electronic devices, positions the market for sustained growth and success in the years to come.

| Report Metric | Details |

| Report Name | Glass-based Photomask Market |

| Accounted market size in year | US$ 2791 million |

| Forecasted market size in 2031 | US$ 4936 million |

| CAGR | 8.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Photronics, Toppan, DNP, Hoya, SK-Electronics, LG Innotek, Taiwan Mask Corporation, Supermask, Nippon Filcon, Compugraphics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |