What is Global Expanded Graphite Sheets Market?

The Global Expanded Graphite Sheets Market is a specialized segment within the broader graphite industry, focusing on the production and distribution of expanded graphite sheets. These sheets are made from natural graphite flakes that have been treated with acid and heat to expand them into a flexible, lightweight material. This process enhances the graphite's natural properties, making it an excellent choice for applications requiring high thermal conductivity, chemical resistance, and flexibility. Expanded graphite sheets are used in various industries, including automotive, chemical, and electronics, due to their ability to withstand extreme temperatures and corrosive environments. They are particularly valued for their sealing and gasketing capabilities, providing reliable solutions in demanding conditions. The market for these sheets is driven by the growing demand for efficient and sustainable materials that can improve performance and reduce environmental impact. As industries continue to seek advanced materials that offer both durability and versatility, the Global Expanded Graphite Sheets Market is poised for steady growth, supported by ongoing innovations and technological advancements in material science.

Ordinary Graphite Gasket, Enhanced Graphite Gasket in the Global Expanded Graphite Sheets Market:

Ordinary Graphite Gaskets and Enhanced Graphite Gaskets are two key products derived from the Global Expanded Graphite Sheets Market, each serving distinct purposes and offering unique benefits. Ordinary Graphite Gaskets are typically made from pure expanded graphite sheets without any additional reinforcements. These gaskets are known for their excellent thermal conductivity, chemical resistance, and ability to withstand high temperatures, making them suitable for a wide range of industrial applications. They are commonly used in environments where sealing performance is critical, such as in pipelines, flanges, and heat exchangers. The flexibility and compressibility of ordinary graphite gaskets allow them to conform to irregular surfaces, ensuring a tight seal even under fluctuating pressure and temperature conditions. On the other hand, Enhanced Graphite Gaskets are designed to offer superior performance by incorporating additional materials or treatments. These gaskets may include metal inserts, such as stainless steel or tanged metal, to provide added strength and stability. The reinforcement enhances the gasket's mechanical properties, making it more resistant to blowouts and mechanical stress. Enhanced Graphite Gaskets are ideal for high-pressure applications and environments where mechanical integrity is paramount. They are often used in the oil and gas industry, power generation, and chemical processing, where reliability and safety are of utmost importance. The choice between ordinary and enhanced graphite gaskets depends on the specific requirements of the application, including factors such as pressure, temperature, and chemical exposure. Both types of gaskets benefit from the inherent properties of expanded graphite, such as its ability to maintain a seal over a wide temperature range and its resistance to chemical attack. As industries continue to demand high-performance sealing solutions, the development and innovation of graphite gaskets remain a focal point within the Global Expanded Graphite Sheets Market. Manufacturers are continually exploring new materials and technologies to enhance the performance and durability of these gaskets, ensuring they meet the evolving needs of various industries. The versatility and adaptability of graphite gaskets make them a valuable component in modern industrial applications, contributing to the efficiency and safety of operations across multiple sectors.

Chemical, Automotive, Pumps and Valves, Other in the Global Expanded Graphite Sheets Market:

The Global Expanded Graphite Sheets Market finds extensive usage across various industries, including chemical, automotive, pumps and valves, and others, due to its unique properties and versatility. In the chemical industry, expanded graphite sheets are highly valued for their chemical resistance and ability to withstand extreme temperatures. They are commonly used in the production of gaskets and seals for chemical processing equipment, where they provide reliable sealing solutions in corrosive environments. The sheets' flexibility and compressibility allow them to conform to irregular surfaces, ensuring a tight seal and preventing leaks. In the automotive industry, expanded graphite sheets are used in various applications, including heat shields, gaskets, and thermal management systems. Their high thermal conductivity and lightweight nature make them ideal for improving fuel efficiency and reducing emissions in vehicles. The sheets help manage heat dissipation in critical components, enhancing the overall performance and longevity of automotive systems. In the pumps and valves sector, expanded graphite sheets are used to manufacture gaskets and seals that can withstand high pressures and temperatures. Their ability to maintain a seal under fluctuating conditions makes them essential for ensuring the reliability and safety of pumps and valves in industrial applications. Additionally, expanded graphite sheets are used in other industries, such as electronics and aerospace, where their thermal and electrical conductivity properties are leveraged for various applications. In electronics, they are used in thermal interface materials to manage heat dissipation in electronic devices, improving performance and preventing overheating. In aerospace, expanded graphite sheets are used in lightweight composite materials, contributing to fuel efficiency and reducing the environmental impact of aircraft. The versatility and adaptability of expanded graphite sheets make them a valuable material in modern industrial applications, driving their demand across multiple sectors. As industries continue to seek advanced materials that offer both performance and sustainability, the Global Expanded Graphite Sheets Market is expected to grow, supported by ongoing innovations and technological advancements in material science.

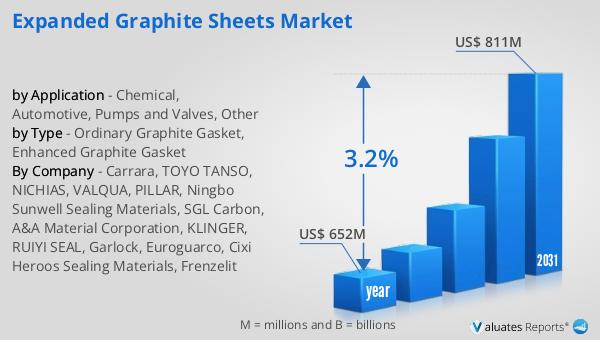

Global Expanded Graphite Sheets Market Outlook:

The global market for Expanded Graphite Sheets was valued at $652 million in 2024 and is anticipated to grow to a revised size of $811 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.2% during the forecast period. This growth trajectory underscores the increasing demand for expanded graphite sheets across various industries, driven by their unique properties and versatility. The market's expansion is fueled by the growing need for efficient and sustainable materials that can enhance performance and reduce environmental impact. As industries continue to seek advanced materials that offer both durability and versatility, the Global Expanded Graphite Sheets Market is poised for steady growth, supported by ongoing innovations and technological advancements in material science. The projected growth in the market size highlights the importance of expanded graphite sheets in modern industrial applications, where they are used in a wide range of sectors, including chemical, automotive, pumps and valves, and others. The market's growth is also supported by the increasing adoption of expanded graphite sheets in emerging economies, where industrialization and infrastructure development are driving demand for high-performance materials. As the market continues to evolve, manufacturers are focusing on developing new products and technologies to meet the evolving needs of various industries, ensuring the continued growth and success of the Global Expanded Graphite Sheets Market.

| Report Metric | Details |

| Report Name | Expanded Graphite Sheets Market |

| Accounted market size in year | US$ 652 million |

| Forecasted market size in 2031 | US$ 811 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Carrara, TOYO TANSO, NICHIAS, VALQUA, PILLAR, Ningbo Sunwell Sealing Materials, SGL Carbon, A&A Material Corporation, KLINGER, RUIYI SEAL, Garlock, Euroguarco, Cixi Heroos Sealing Materials, Frenzelit |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |