What is Global Flexible Expanded Graphite Foil Market?

The Global Flexible Expanded Graphite Foil Market is a specialized segment within the broader graphite industry, focusing on the production and application of flexible expanded graphite foils. These foils are made from natural graphite flakes that are processed to expand and then compressed into thin, flexible sheets. This material is known for its excellent thermal and electrical conductivity, chemical resistance, and flexibility, making it highly valuable in various industrial applications. The market for these foils is driven by their use in industries such as electronics, automotive, chemical, and energy, where they serve as critical components in gaskets, seals, heat dissipation materials, and more. The demand for flexible expanded graphite foils is increasing due to the growing need for efficient thermal management solutions and the rising adoption of electric vehicles, which require advanced materials for battery and electronic component protection. As industries continue to seek materials that offer high performance and sustainability, the Global Flexible Expanded Graphite Foil Market is poised for significant growth, driven by technological advancements and the expanding scope of applications.

Carbon Content: 98%-99%, Carbon Content: >99% in the Global Flexible Expanded Graphite Foil Market:

In the Global Flexible Expanded Graphite Foil Market, carbon content is a critical factor that determines the quality and performance of the graphite foil. The carbon content in these foils typically ranges from 98% to over 99%, with each level offering distinct properties and advantages. Foils with a carbon content of 98% to 99% are widely used due to their balance of cost and performance. They offer excellent thermal conductivity and chemical resistance, making them suitable for a variety of applications, including gaskets and seals in the chemical and automotive industries. These foils are also used in heat exchangers and as thermal interface materials in electronics, where efficient heat dissipation is crucial. On the other hand, foils with a carbon content greater than 99% are considered premium products, offering superior performance characteristics. These high-purity foils provide enhanced thermal and electrical conductivity, making them ideal for high-performance applications in the electronics and aerospace industries. They are often used in situations where maximum efficiency and reliability are required, such as in the production of advanced batteries and fuel cells. The choice between different carbon content levels depends on the specific requirements of the application, including factors such as thermal management needs, chemical exposure, and budget constraints. As the demand for high-performance materials continues to grow, manufacturers in the Global Flexible Expanded Graphite Foil Market are focusing on optimizing the carbon content of their products to meet the diverse needs of their customers. This involves not only improving the purity of the graphite but also enhancing the manufacturing processes to ensure consistent quality and performance. The ongoing research and development efforts in this field are expected to lead to the introduction of new and improved products that offer even greater efficiency and reliability. As industries continue to evolve and new applications for flexible expanded graphite foils emerge, the importance of carbon content as a key differentiator in the market is likely to increase. Companies that can offer a wide range of products with varying carbon content levels will be well-positioned to capitalize on the growing demand for these versatile materials.

Chemical, Oil and Gas, Other in the Global Flexible Expanded Graphite Foil Market:

The Global Flexible Expanded Graphite Foil Market finds extensive usage across various industries, including chemical, oil and gas, and others, due to its unique properties and versatility. In the chemical industry, flexible expanded graphite foils are primarily used for their excellent chemical resistance and sealing capabilities. They are commonly employed in the production of gaskets and seals that are used in chemical processing equipment, where they help prevent leaks and ensure the safe and efficient operation of machinery. The foils' ability to withstand harsh chemical environments and high temperatures makes them an ideal choice for applications in this sector. In the oil and gas industry, flexible expanded graphite foils are valued for their durability and reliability in extreme conditions. They are used in the construction of seals and gaskets for pipelines, valves, and other critical components, where they help maintain the integrity of the system and prevent leaks. The foils' excellent thermal conductivity also makes them suitable for use in heat exchangers and other equipment that requires efficient heat transfer. Additionally, their flexibility allows them to conform to irregular surfaces, ensuring a tight seal even in challenging environments. Beyond the chemical and oil and gas industries, flexible expanded graphite foils are used in a variety of other applications. In the electronics industry, they serve as thermal interface materials, helping to dissipate heat from electronic components and improve the performance and longevity of devices. In the automotive sector, they are used in the production of gaskets and seals for engines and exhaust systems, where they help reduce emissions and improve fuel efficiency. The foils' lightweight and flexible nature also make them suitable for use in aerospace applications, where they contribute to weight reduction and improved thermal management. As industries continue to seek materials that offer high performance and sustainability, the demand for flexible expanded graphite foils is expected to grow. Manufacturers are focusing on developing new products and improving existing ones to meet the evolving needs of their customers. This includes enhancing the foils' thermal and electrical conductivity, chemical resistance, and mechanical strength, as well as exploring new applications and markets. The ongoing research and development efforts in this field are likely to lead to the introduction of innovative solutions that further expand the scope of applications for flexible expanded graphite foils.

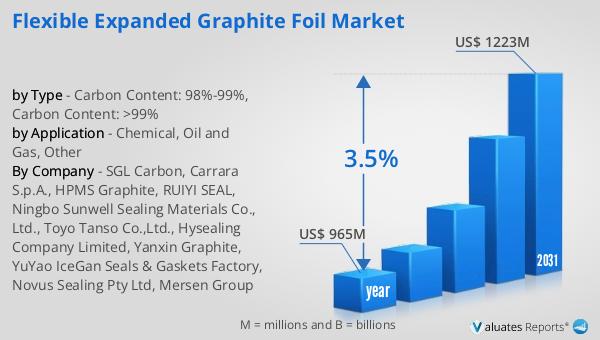

Global Flexible Expanded Graphite Foil Market Outlook:

The global market for Flexible Expanded Graphite Foil was valued at $965 million in 2024, and it is anticipated to grow to a revised size of $1,223 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.5% during the forecast period. This growth trajectory underscores the increasing demand for flexible expanded graphite foils across various industries, driven by their unique properties and versatility. The market's expansion is fueled by the rising need for efficient thermal management solutions, particularly in the electronics and automotive sectors, where these foils play a crucial role in heat dissipation and component protection. Additionally, the growing adoption of electric vehicles and advancements in battery technology are contributing to the market's growth, as flexible expanded graphite foils are used in the production of advanced batteries and fuel cells. As industries continue to seek materials that offer high performance and sustainability, the Global Flexible Expanded Graphite Foil Market is poised for significant growth, driven by technological advancements and the expanding scope of applications. Companies that can offer a wide range of products with varying carbon content levels will be well-positioned to capitalize on the growing demand for these versatile materials. The ongoing research and development efforts in this field are expected to lead to the introduction of new and improved products that offer even greater efficiency and reliability.

| Report Metric | Details |

| Report Name | Flexible Expanded Graphite Foil Market |

| Accounted market size in year | US$ 965 million |

| Forecasted market size in 2031 | US$ 1223 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SGL Carbon, Carrara S.p.A., HPMS Graphite, RUIYI SEAL, Ningbo Sunwell Sealing Materials Co., Ltd., Toyo Tanso Co.,Ltd., Hysealing Company Limited, Yanxin Graphite, YuYao IceGan Seals & Gaskets Factory, Novus Sealing Pty Ltd, Mersen Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |