What is Global Carbon Fiber Soft Felt Market?

The Global Carbon Fiber Soft Felt Market is a specialized segment within the broader carbon fiber industry, focusing on the production and application of soft felt materials made from carbon fibers. These materials are known for their lightweight, high thermal insulation, and excellent electrical conductivity properties. Carbon fiber soft felt is primarily used in high-temperature environments and applications where thermal management is crucial. The market for these materials is driven by their increasing use in various industries, including aerospace, automotive, electronics, and energy. As industries continue to seek materials that offer superior performance while reducing weight and energy consumption, the demand for carbon fiber soft felt is expected to grow. This market is characterized by ongoing research and development efforts aimed at enhancing the properties of carbon fiber soft felt, making it more versatile and cost-effective. Additionally, the market is influenced by environmental regulations and the push for sustainable materials, as carbon fiber soft felt can contribute to energy efficiency and reduced emissions. Overall, the Global Carbon Fiber Soft Felt Market represents a dynamic and evolving sector with significant potential for growth and innovation.

Pan-Based Carbon Fiber, Rayon-Based Carbon Fiber, Pitch-Based Carbon Fiber in the Global Carbon Fiber Soft Felt Market:

Pan-Based Carbon Fiber, Rayon-Based Carbon Fiber, and Pitch-Based Carbon Fiber are three primary types of carbon fibers used in the Global Carbon Fiber Soft Felt Market, each with distinct characteristics and applications. Pan-Based Carbon Fiber is derived from polyacrylonitrile (PAN) and is the most widely used type due to its high strength and modulus. It is favored in applications requiring superior mechanical properties, such as aerospace and automotive components. The production process involves stabilizing and carbonizing PAN fibers, resulting in a material that offers excellent tensile strength and stiffness. Rayon-Based Carbon Fiber, on the other hand, is made from regenerated cellulose fibers. Although it is less common than PAN-based fibers, it is valued for its high thermal insulation properties, making it suitable for applications in high-temperature environments, such as furnace linings and thermal insulation. The production of rayon-based carbon fiber involves carbonizing rayon fibers, which results in a material with a lower density and thermal conductivity compared to PAN-based fibers. Pitch-Based Carbon Fiber is produced from petroleum or coal tar pitch and is known for its high thermal conductivity and low thermal expansion. This type of carbon fiber is used in applications where thermal management is critical, such as heat exchangers and electronic components. The production process involves spinning pitch into fibers, followed by stabilization and carbonization. Each type of carbon fiber offers unique advantages, and the choice of material depends on the specific requirements of the application. The Global Carbon Fiber Soft Felt Market is driven by the diverse applications of these materials, as industries continue to seek solutions that offer a balance of performance, cost, and sustainability. As research and development efforts continue, new formulations and production techniques are expected to enhance the properties of carbon fiber soft felt, expanding its potential applications and driving market growth.

Stationary Energy Storage Batteries, High Temperature Furnace Linings, Acid Gas Mist Eliminators, Carbon Composite Materials, Other in the Global Carbon Fiber Soft Felt Market:

The Global Carbon Fiber Soft Felt Market finds applications in various areas, including Stationary Energy Storage Batteries, High Temperature Furnace Linings, Acid Gas Mist Eliminators, Carbon Composite Materials, and others. In Stationary Energy Storage Batteries, carbon fiber soft felt is used as an electrode material due to its excellent electrical conductivity and lightweight properties. This application is crucial for improving the efficiency and performance of energy storage systems, which are essential for renewable energy integration and grid stability. In High Temperature Furnace Linings, carbon fiber soft felt is used as an insulating material due to its high thermal resistance and low thermal conductivity. This application helps in reducing energy consumption and improving the efficiency of industrial furnaces, which are used in various manufacturing processes. Acid Gas Mist Eliminators utilize carbon fiber soft felt for its chemical resistance and filtration properties. This application is important for reducing emissions and improving air quality in industrial settings. Carbon Composite Materials incorporate carbon fiber soft felt to enhance the mechanical properties and reduce the weight of composite structures. This application is widely used in aerospace, automotive, and sports equipment industries, where performance and weight reduction are critical. Other applications of carbon fiber soft felt include its use in electronic components, heat exchangers, and thermal management systems. The versatility and unique properties of carbon fiber soft felt make it an attractive material for a wide range of applications, driving its demand in the global market. As industries continue to seek materials that offer superior performance and sustainability, the Global Carbon Fiber Soft Felt Market is expected to grow, with ongoing research and development efforts aimed at expanding its applications and improving its properties.

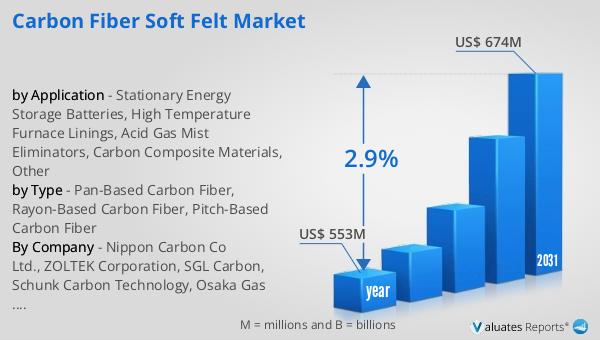

Global Carbon Fiber Soft Felt Market Outlook:

The global market for Carbon Fiber Soft Felt was valued at approximately 553 million US dollars in 2024. It is anticipated to grow to a revised size of around 674 million US dollars by 2031, reflecting a compound annual growth rate (CAGR) of 2.9% during the forecast period. This growth is indicative of the increasing demand for carbon fiber soft felt across various industries, driven by its unique properties and versatile applications. The market's expansion is supported by the ongoing advancements in production technologies and the development of new formulations that enhance the performance and cost-effectiveness of carbon fiber soft felt. Additionally, the push for sustainable materials and energy-efficient solutions is contributing to the market's growth, as carbon fiber soft felt offers significant advantages in terms of weight reduction and thermal management. The market outlook suggests a positive trajectory for the Global Carbon Fiber Soft Felt Market, with opportunities for innovation and expansion in various sectors. As industries continue to prioritize performance, efficiency, and sustainability, the demand for carbon fiber soft felt is expected to rise, driving market growth and creating new opportunities for manufacturers and suppliers.

| Report Metric | Details |

| Report Name | Carbon Fiber Soft Felt Market |

| Accounted market size in year | US$ 553 million |

| Forecasted market size in 2031 | US$ 674 million |

| CAGR | 2.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nippon Carbon Co Ltd., ZOLTEK Corporation, SGL Carbon, Schunk Carbon Technology, Osaka Gas Chemicals Co., Ltd., Kureha Corporation, Beijing Great Wall Co., Ltd., CFC Carbon Co. LTD., Sinotek Materials Co., Olmec Advanced Materials, Mersen Graphite |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |