What is Global Centrifugal Pump for Pharmaceutical Market?

The Global Centrifugal Pump for Pharmaceutical Market is a specialized segment within the broader pharmaceutical industry, focusing on the use of centrifugal pumps in various pharmaceutical processes. These pumps are essential for moving fluids through different stages of drug manufacturing, ensuring that the processes are efficient, hygienic, and meet stringent regulatory standards. Centrifugal pumps are favored in the pharmaceutical sector due to their ability to handle a wide range of fluid viscosities, temperatures, and chemical compositions. They are designed to minimize contamination risks, which is crucial in maintaining the purity and efficacy of pharmaceutical products. The market for these pumps is driven by the growing demand for pharmaceuticals worldwide, advancements in pump technology, and the increasing need for efficient and reliable fluid handling solutions in drug production. As pharmaceutical companies strive to enhance their production capabilities and meet global health demands, the role of centrifugal pumps becomes increasingly vital. This market is characterized by continuous innovation, with manufacturers focusing on developing pumps that offer improved energy efficiency, reduced maintenance costs, and enhanced operational reliability.

Single Suction Pumps, Double Suction Pumps in the Global Centrifugal Pump for Pharmaceutical Market:

Single Suction Pumps and Double Suction Pumps are two primary types of centrifugal pumps used in the pharmaceutical industry, each with distinct features and applications. Single Suction Pumps, also known as end-suction pumps, have a single inlet through which the fluid enters the impeller. These pumps are typically used for applications requiring moderate flow rates and pressures. They are compact, easy to maintain, and cost-effective, making them suitable for smaller pharmaceutical operations or specific processes within larger facilities. Single Suction Pumps are often employed in applications where space is limited, and the fluid being pumped is relatively clean and free of large particulates. Their design allows for straightforward installation and operation, which is advantageous in environments where downtime must be minimized. On the other hand, Double Suction Pumps are designed with two inlets, allowing fluid to enter the impeller from both sides. This design feature enables the pump to handle higher flow rates and pressures compared to Single Suction Pumps. Double Suction Pumps are ideal for large-scale pharmaceutical operations where high-volume fluid transfer is required. They are often used in processes that involve the movement of large quantities of water or other fluids essential for drug manufacturing. The balanced design of Double Suction Pumps reduces axial thrust, leading to longer bearing life and improved reliability. This makes them a preferred choice for critical applications where pump failure could lead to significant production losses or quality issues. In the context of the Global Centrifugal Pump for Pharmaceutical Market, the choice between Single Suction and Double Suction Pumps depends on several factors, including the specific requirements of the pharmaceutical process, the nature of the fluid being pumped, and the operational conditions. For instance, Single Suction Pumps might be chosen for processes that require precise control over fluid flow and pressure, while Double Suction Pumps might be selected for their ability to handle larger volumes and provide consistent performance under demanding conditions. Both types of pumps are subject to rigorous quality standards and regulatory requirements, ensuring that they meet the high expectations of the pharmaceutical industry in terms of hygiene, safety, and efficiency. Manufacturers of centrifugal pumps for the pharmaceutical market are continually innovating to enhance the performance and reliability of both Single Suction and Double Suction Pumps. Advances in materials science have led to the development of pumps that can withstand corrosive and abrasive fluids, extending their lifespan and reducing maintenance needs. Additionally, the integration of smart technologies, such as sensors and IoT connectivity, is enabling real-time monitoring and predictive maintenance, further improving the operational efficiency of these pumps. As the pharmaceutical industry continues to evolve, the demand for advanced centrifugal pumps that can meet the sector's stringent requirements is expected to grow, driving further innovation and development in this market segment.

Direct Sales, Indirect Sales in the Global Centrifugal Pump for Pharmaceutical Market:

The usage of Global Centrifugal Pumps in the pharmaceutical market can be categorized into two main sales channels: Direct Sales and Indirect Sales. Direct Sales involve the sale of centrifugal pumps directly from manufacturers to pharmaceutical companies. This sales channel is often preferred by large pharmaceutical firms that require customized pump solutions tailored to their specific production needs. By engaging directly with manufacturers, these companies can collaborate on the design and development of pumps that meet their unique operational requirements, ensuring optimal performance and compliance with industry standards. Direct Sales also allow for better communication and coordination between the pump manufacturer and the pharmaceutical company, facilitating timely delivery, installation, and support services. Indirect Sales, on the other hand, involve the distribution of centrifugal pumps through intermediaries such as distributors, agents, or resellers. This sales channel is particularly beneficial for smaller pharmaceutical companies or those located in regions where direct access to pump manufacturers is limited. Indirect Sales provide these companies with access to a wide range of pump options and the expertise of local distributors who understand the specific needs and challenges of the regional market. Distributors often offer additional services such as installation, maintenance, and technical support, making it easier for pharmaceutical companies to integrate centrifugal pumps into their operations. In the Global Centrifugal Pump for Pharmaceutical Market, both Direct and Indirect Sales channels play a crucial role in ensuring that pharmaceutical companies have access to the pumps they need to maintain efficient and reliable production processes. The choice between these sales channels depends on various factors, including the size and location of the pharmaceutical company, the complexity of the pump requirements, and the level of customization needed. For instance, a large multinational pharmaceutical company with complex production needs might opt for Direct Sales to ensure that their specific requirements are met, while a smaller regional company might choose Indirect Sales for the convenience and support offered by local distributors. Both sales channels are supported by a network of service providers who offer installation, maintenance, and repair services, ensuring that centrifugal pumps operate efficiently and with minimal downtime. As the pharmaceutical industry continues to grow and evolve, the demand for centrifugal pumps is expected to increase, driving further development and expansion of both Direct and Indirect Sales channels. Manufacturers and distributors are likely to continue investing in their sales and support networks to meet the needs of the pharmaceutical market, ensuring that companies have access to the latest pump technologies and solutions.

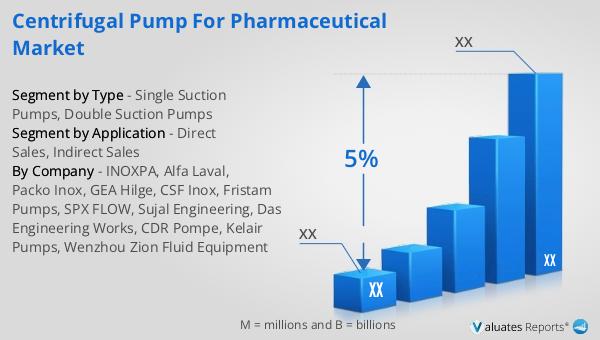

Global Centrifugal Pump for Pharmaceutical Market Outlook:

In 2022, the global pharmaceutical market reached a valuation of 1,475 billion USD, marking a steady growth trajectory with a compound annual growth rate (CAGR) of 5% projected over the next six years. This growth reflects the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, rising prevalence of chronic diseases, and advancements in drug development and manufacturing technologies. In comparison, the chemical drug market has also experienced growth, with its value rising from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This indicates a robust demand for chemical drugs, which continue to play a significant role in the global healthcare landscape. The expansion of the pharmaceutical market, including the chemical drug segment, underscores the critical role of centrifugal pumps in supporting the industry's growth. As pharmaceutical companies strive to enhance their production capabilities and meet the increasing demand for drugs, the need for efficient and reliable fluid handling solutions becomes more pronounced. Centrifugal pumps, with their ability to handle a wide range of fluid viscosities and compositions, are essential for ensuring that pharmaceutical manufacturing processes are efficient, hygienic, and compliant with regulatory standards. The ongoing growth of the pharmaceutical market is expected to drive further innovation and development in the Global Centrifugal Pump for Pharmaceutical Market, as manufacturers seek to provide advanced pump solutions that meet the evolving needs of the industry.

| Report Metric | Details |

| Report Name | Centrifugal Pump for Pharmaceutical Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | INOXPA, Alfa Laval, Packo Inox, GEA Hilge, CSF Inox, Fristam Pumps, SPX FLOW, Sujal Engineering, Das Engineering Works, CDR Pompe, Kelair Pumps, Wenzhou Zion Fluid Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |