What is Global Micro-Welding Systems Market?

The Global Micro-Welding Systems Market is a specialized segment within the broader welding industry, focusing on the precision joining of small components and materials. This market is driven by the increasing demand for miniaturized products across various industries, including electronics, automotive, aerospace, and medical devices. Micro-welding systems are designed to perform welding tasks at a microscopic level, ensuring high precision and minimal thermal distortion. These systems are essential for applications where traditional welding methods would be too coarse or damaging. The market encompasses various technologies, such as laser micro-welding, TIG (Tungsten Inert Gas) micro-welding, and resistance micro-welding, each offering unique advantages depending on the application. As industries continue to innovate and push the boundaries of miniaturization, the demand for advanced micro-welding systems is expected to grow. This growth is further supported by technological advancements that enhance the efficiency, accuracy, and versatility of micro-welding systems. Overall, the Global Micro-Welding Systems Market plays a crucial role in enabling the production of high-quality, reliable, and durable products across multiple sectors, making it an integral part of modern manufacturing processes.

Laser Micro-Welding, TIG Micro-Welding, Resistance Micro-Welding in the Global Micro-Welding Systems Market:

Laser micro-welding is a prominent technology within the Global Micro-Welding Systems Market, known for its precision and ability to weld small, intricate components with minimal heat input. This method uses a focused laser beam to melt and join materials, making it ideal for applications requiring high accuracy and minimal thermal distortion. Laser micro-welding is widely used in the electronics industry for assembling delicate components, such as microchips and sensors, where precision is paramount. Its ability to produce clean, strong welds without the need for additional filler materials makes it a preferred choice for manufacturers seeking to maintain the integrity of their products. Additionally, laser micro-welding is highly adaptable, capable of working with a variety of materials, including metals, plastics, and ceramics, further broadening its application scope. TIG micro-welding, or Tungsten Inert Gas micro-welding, is another critical technology in the micro-welding market. This method employs a non-consumable tungsten electrode to produce the weld, with an inert gas, typically argon, shielding the weld area to prevent oxidation. TIG micro-welding is renowned for its precision and control, allowing operators to create high-quality welds on thin and delicate materials. It is particularly useful in industries where the aesthetic appearance of the weld is important, such as in the production of medical devices and high-end consumer electronics. The ability to weld without filler material also reduces the risk of contamination, making TIG micro-welding a reliable choice for applications requiring stringent quality standards. Resistance micro-welding is a process that uses electrical resistance to generate heat and join materials. This method is highly efficient and suitable for high-volume production environments, such as the automotive and aerospace industries. Resistance micro-welding is characterized by its speed and repeatability, making it ideal for applications where consistent weld quality is essential. The process involves clamping the materials between electrodes and passing a current through them, causing localized heating and fusion. This technique is particularly effective for joining thin sheets of metal and is often used in the assembly of battery packs, sensors, and other electronic components. Its ability to produce strong, reliable welds quickly and efficiently makes resistance micro-welding a valuable tool in modern manufacturing. Each of these micro-welding technologies offers distinct advantages, catering to the diverse needs of various industries. As the demand for miniaturized and high-precision products continues to rise, the Global Micro-Welding Systems Market is poised to expand, driven by the ongoing development and refinement of these advanced welding techniques. The integration of automation and digital technologies further enhances the capabilities of micro-welding systems, enabling manufacturers to achieve higher levels of precision, efficiency, and quality in their production processes.

Electronics, Automotive, Aerospace & Defense, Medical Devices, Others in the Global Micro-Welding Systems Market:

The Global Micro-Welding Systems Market finds extensive applications across several key industries, each benefiting from the precision and reliability offered by micro-welding technologies. In the electronics sector, micro-welding systems are indispensable for the assembly of small, intricate components such as microchips, circuit boards, and sensors. The ability to create precise, clean welds without damaging sensitive electronic parts is crucial for maintaining the performance and longevity of electronic devices. As consumer electronics continue to evolve towards smaller, more powerful designs, the demand for advanced micro-welding solutions is expected to grow. In the automotive industry, micro-welding systems are used to join various components, including sensors, battery packs, and electrical connectors. The precision and strength of micro-welds are essential for ensuring the safety and reliability of automotive systems, particularly as vehicles become more technologically advanced and reliant on electronic components. Additionally, the push towards electric vehicles has increased the need for efficient and reliable welding solutions for battery assembly, further driving the demand for micro-welding systems in this sector. The aerospace and defense industries also rely heavily on micro-welding technologies for the production of high-performance components. The ability to create strong, lightweight welds is critical for aerospace applications, where weight reduction is a constant priority. Micro-welding systems are used to assemble components such as sensors, fuel systems, and structural elements, ensuring that they meet the stringent quality and safety standards required in these industries. The precision and reliability of micro-welding are particularly important in defense applications, where the performance and durability of equipment can have significant implications. In the medical devices industry, micro-welding systems are used to manufacture a wide range of products, from surgical instruments to implantable devices. The ability to create precise, clean welds is essential for ensuring the safety and effectiveness of medical devices, which must meet strict regulatory standards. Micro-welding technologies enable manufacturers to produce high-quality, reliable devices that can withstand the rigors of medical use. As the demand for advanced medical devices continues to grow, driven by an aging population and increasing healthcare needs, the role of micro-welding systems in this industry is expected to expand. Beyond these primary industries, micro-welding systems are also used in various other sectors, including telecommunications, energy, and consumer goods. The versatility and precision of micro-welding technologies make them suitable for a wide range of applications, from the assembly of small electronic components to the production of complex mechanical systems. As industries continue to innovate and develop new products, the demand for advanced micro-welding solutions is likely to increase, driving further growth in the Global Micro-Welding Systems Market.

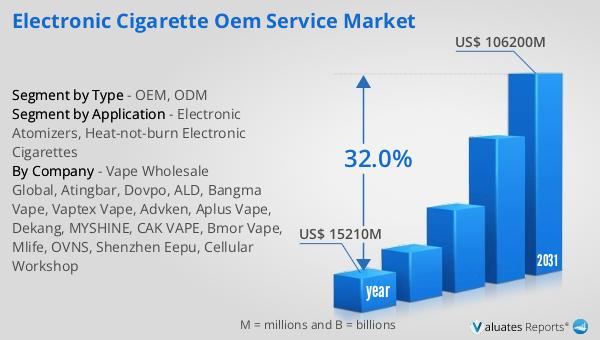

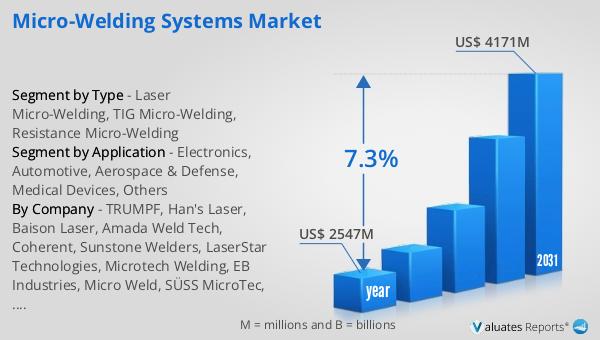

Global Micro-Welding Systems Market Outlook:

The global market for micro-welding systems, valued at approximately $2,547 million in 2024, is on a growth trajectory, with projections indicating it will reach around $4,171 million by 2031. This expansion represents a compound annual growth rate (CAGR) of 7.3% over the forecast period. This growth is driven by the increasing demand for precision welding solutions across various industries, including electronics, automotive, aerospace, and medical devices. As these industries continue to innovate and develop smaller, more complex products, the need for advanced micro-welding systems is expected to rise. The market's growth is further supported by technological advancements that enhance the efficiency, accuracy, and versatility of micro-welding systems. These advancements enable manufacturers to achieve higher levels of precision and quality in their production processes, meeting the evolving needs of their customers. Additionally, the integration of automation and digital technologies into micro-welding systems is expected to drive further growth, as manufacturers seek to improve productivity and reduce costs. Overall, the global micro-welding systems market is poised for significant growth, driven by the increasing demand for high-precision welding solutions and the ongoing development of advanced technologies.

| Report Metric | Details |

| Report Name | Micro-Welding Systems Market |

| Accounted market size in year | US$ 2547 million |

| Forecasted market size in 2031 | US$ 4171 million |

| CAGR | 7.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TRUMPF, Han's Laser, Baison Laser, Amada Weld Tech, Coherent, Sunstone Welders, LaserStar Technologies, Microtech Welding, EB Industries, Micro Weld, SÜSS MicroTec, Schunk Group, Voestalpine Böhler Welding, KUKA, MUNSCH, SST MicroWelding |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |