What is Global Carbon Carbon Composite Sheet Market?

The Global Carbon Carbon Composite Sheet Market is a specialized segment within the broader composite materials industry, focusing on the production and application of carbon-carbon composite sheets. These sheets are made from carbon fibers reinforced with a carbon matrix, offering exceptional strength, lightweight properties, and high thermal resistance. They are particularly valued in industries that demand materials capable of withstanding extreme temperatures and mechanical stress, such as aerospace, automotive, and metallurgy. The market for these composite sheets is driven by the increasing demand for advanced materials that can enhance performance and efficiency in various applications. As industries continue to innovate and seek materials that offer superior performance, the demand for carbon-carbon composite sheets is expected to grow. These sheets are not only used in high-tech industries but are also finding applications in other sectors due to their unique properties. The market is characterized by ongoing research and development efforts aimed at improving the properties of these composites and expanding their range of applications. As a result, the Global Carbon Carbon Composite Sheet Market is poised for significant growth, driven by technological advancements and the increasing need for high-performance materials.

Chemical Vapor Deposition, Liquid Impregnation in the Global Carbon Carbon Composite Sheet Market:

Chemical Vapor Deposition (CVD) and Liquid Impregnation are two critical processes in the production of carbon-carbon composite sheets, each contributing to the unique properties that make these materials highly sought after in various industries. CVD is a process where gaseous reactants are introduced into a chamber containing a substrate, in this case, carbon fibers. The reactants decompose on the substrate surface, forming a solid material that coats the fibers. This method is particularly advantageous for creating a uniform carbon matrix around the fibers, enhancing the composite's strength and thermal stability. The CVD process allows for precise control over the thickness and composition of the deposited layer, making it possible to tailor the properties of the composite to specific applications. This precision is crucial in industries like aerospace and automotive, where materials must meet stringent performance criteria. On the other hand, Liquid Impregnation involves immersing carbon fibers in a liquid precursor, which is then cured to form a solid matrix. This method is often used to produce composites with a high degree of porosity, which can be beneficial in applications requiring lightweight materials with good thermal insulation properties. The choice between CVD and Liquid Impregnation depends on the desired properties of the final product and the specific requirements of the application. Both methods have their advantages and limitations, and ongoing research is focused on optimizing these processes to enhance the performance of carbon-carbon composite sheets. In the Global Carbon Carbon Composite Sheet Market, the ability to produce materials with tailored properties is a significant competitive advantage, driving innovation and growth. As industries continue to demand materials that offer superior performance, the role of advanced manufacturing processes like CVD and Liquid Impregnation will become increasingly important. These processes not only enhance the properties of carbon-carbon composites but also expand their range of applications, making them indispensable in the quest for high-performance materials. The development of new techniques and the refinement of existing processes are expected to play a crucial role in the future of the Global Carbon Carbon Composite Sheet Market, as manufacturers strive to meet the evolving needs of their customers.

Aerospace, Metallurgy, Automotive, Other in the Global Carbon Carbon Composite Sheet Market:

The Global Carbon Carbon Composite Sheet Market finds extensive usage across various industries, each leveraging the unique properties of these materials to enhance performance and efficiency. In the aerospace sector, carbon-carbon composite sheets are prized for their lightweight and high-strength characteristics, which are essential for improving fuel efficiency and payload capacity. These composites are used in critical components such as heat shields, brake discs, and structural parts, where their ability to withstand extreme temperatures and mechanical stress is invaluable. The aerospace industry's continuous push for more efficient and reliable materials ensures a steady demand for carbon-carbon composites. In metallurgy, these sheets are used in high-temperature furnaces and reactors, where their thermal stability and resistance to thermal shock make them ideal for lining and insulation. The automotive industry also benefits from the use of carbon-carbon composite sheets, particularly in high-performance vehicles where weight reduction and enhanced strength are crucial. These composites are used in brake systems, clutches, and other components that require high thermal resistance and mechanical strength. Beyond these industries, carbon-carbon composite sheets are finding applications in other areas such as electronics, where their thermal conductivity and lightweight properties are advantageous. The versatility of these materials makes them suitable for a wide range of applications, driving their adoption across various sectors. As industries continue to seek materials that offer superior performance and efficiency, the demand for carbon-carbon composite sheets is expected to grow. The Global Carbon Carbon Composite Sheet Market is characterized by ongoing innovation and development, as manufacturers strive to meet the evolving needs of their customers. The ability to produce materials with tailored properties is a significant competitive advantage, driving growth and expansion in this market. As a result, carbon-carbon composite sheets are poised to play an increasingly important role in the future of various industries, offering solutions that enhance performance and efficiency.

Global Carbon Carbon Composite Sheet Market Outlook:

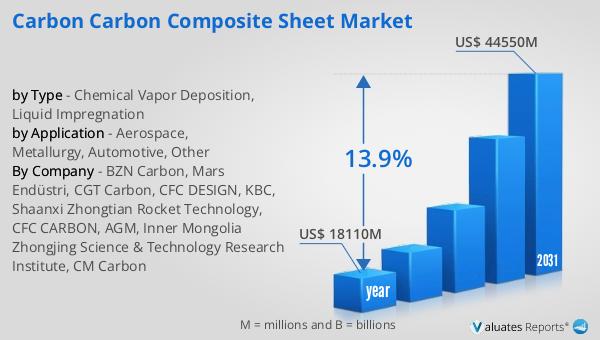

The outlook for the Global Carbon Carbon Composite Sheet Market is promising, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately $18.11 billion, reflecting the increasing demand for high-performance materials across various industries. By 2031, the market is projected to reach an impressive $44.55 billion, driven by a compound annual growth rate (CAGR) of 13.9% during the forecast period. This growth is indicative of the expanding applications and technological advancements in the field of carbon-carbon composites. The market's robust growth trajectory is fueled by the continuous innovation and development of new manufacturing processes, which enhance the properties and performance of these materials. As industries such as aerospace, automotive, and metallurgy continue to seek materials that offer superior strength, lightweight properties, and thermal resistance, the demand for carbon-carbon composite sheets is expected to rise. The market's expansion is also supported by the increasing focus on sustainability and energy efficiency, as these composites contribute to reducing weight and improving fuel efficiency in various applications. The Global Carbon Carbon Composite Sheet Market is poised for significant growth, driven by technological advancements and the increasing need for high-performance materials. As manufacturers continue to innovate and develop new solutions, the market is expected to expand, offering opportunities for growth and development in the coming years.

| Report Metric | Details |

| Report Name | Carbon Carbon Composite Sheet Market |

| Accounted market size in year | US$ 18110 million |

| Forecasted market size in 2031 | US$ 44550 million |

| CAGR | 13.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | BZN Carbon, Mars Endüstri, CGT Carbon, CFC DESIGN, KBC, Shaanxi Zhongtian Rocket Technology, CFC CARBON, AGM, Inner Mongolia Zhongjing Science & Technology Research Institute, CM Carbon |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |