What is Global High Temperature Wire Insulators Market?

The Global High Temperature Wire Insulators Market is a specialized segment within the broader electrical insulation industry, focusing on materials that can withstand extreme temperatures. These insulators are crucial for ensuring the safe and efficient operation of electrical systems in environments where high heat is a factor. They are used in various applications, from industrial machinery to consumer electronics, where they prevent electrical currents from escaping their intended pathways, thus avoiding short circuits and potential hazards. The market for these insulators is driven by the increasing demand for high-performance materials in industries such as automotive, aerospace, and electronics, where components are often exposed to high temperatures. As technology advances, the need for reliable and durable insulation solutions becomes more critical, pushing manufacturers to innovate and improve their products. This market is characterized by a diverse range of materials, including ceramics, glass, and composites, each offering unique properties that cater to specific applications. The growth of this market is also influenced by regulatory standards and environmental considerations, as industries seek to improve energy efficiency and reduce their carbon footprint. Overall, the Global High Temperature Wire Insulators Market plays a vital role in supporting the infrastructure of modern technology and industry.

Porcelain Insulators, Glass Insulators, Composite Insulators in the Global High Temperature Wire Insulators Market:

Porcelain insulators, glass insulators, and composite insulators are three primary types of materials used in the Global High Temperature Wire Insulators Market, each offering distinct advantages and applications. Porcelain insulators are made from a type of ceramic material that is known for its excellent electrical insulation properties and mechanical strength. They are widely used in high-voltage applications such as power transmission and distribution systems. Porcelain insulators are highly resistant to environmental factors like moisture and pollution, making them suitable for outdoor use. Their durability and reliability have made them a staple in the electrical industry for decades. However, they can be heavy and brittle, which may limit their use in certain applications where weight and flexibility are critical considerations. Glass insulators, on the other hand, are made from toughened glass and are known for their transparency and aesthetic appeal. They offer excellent electrical insulation and are resistant to weathering and UV radiation. Glass insulators are often used in power lines and substations, where their ability to withstand high temperatures and environmental stress is crucial. One of the key advantages of glass insulators is their ability to self-clean, as their smooth surface prevents the accumulation of dirt and pollutants. This feature reduces maintenance requirements and enhances their longevity. However, like porcelain, glass insulators can be heavy and fragile, which may pose challenges in certain applications. Composite insulators are a more recent innovation in the field of high-temperature wire insulation. They are made from a combination of materials, typically featuring a fiberglass core with a polymeric housing. Composite insulators are lightweight, flexible, and highly resistant to mechanical stress, making them ideal for applications where weight and flexibility are important. They also offer excellent electrical insulation and are resistant to environmental factors such as moisture, UV radiation, and pollution. Composite insulators are increasingly being used in power transmission and distribution systems, as well as in other high-temperature applications. Their versatility and performance make them a popular choice for modern electrical systems. However, they can be more expensive than traditional materials like porcelain and glass, which may limit their adoption in some markets. Overall, each type of insulator has its own set of advantages and limitations, and the choice of material depends on the specific requirements of the application. The Global High Temperature Wire Insulators Market continues to evolve as new materials and technologies are developed to meet the growing demand for high-performance insulation solutions.

Chemical Industry, Automotive Industry, Aerospace Industry, Electronic Industry in the Global High Temperature Wire Insulators Market:

The Global High Temperature Wire Insulators Market finds extensive usage across various industries, including the chemical, automotive, aerospace, and electronic sectors, each with its unique set of requirements and challenges. In the chemical industry, high temperature wire insulators are essential for ensuring the safe operation of equipment and machinery that are exposed to extreme temperatures and corrosive environments. These insulators help prevent electrical failures and maintain the integrity of electrical systems, which is crucial for the continuous and efficient operation of chemical processes. The automotive industry also relies heavily on high temperature wire insulators, particularly in the manufacturing of electric and hybrid vehicles. These vehicles require advanced insulation solutions to manage the high temperatures generated by their electrical systems and to ensure the safety and reliability of their components. High temperature wire insulators are used in various parts of the vehicle, including the battery, motor, and power electronics, where they help prevent electrical shorts and improve energy efficiency. In the aerospace industry, high temperature wire insulators are critical for the safe and efficient operation of aircraft and spacecraft. These insulators are used in a wide range of applications, from the wiring systems of commercial airplanes to the electrical components of satellites and space probes. The extreme conditions encountered in aerospace applications, such as high temperatures, pressure, and radiation, require insulation materials that can withstand these challenges while maintaining their performance and reliability. High temperature wire insulators play a vital role in ensuring the safety and functionality of aerospace systems, contributing to the overall success of missions and operations. The electronic industry is another major user of high temperature wire insulators, as the demand for smaller, more powerful, and energy-efficient devices continues to grow. These insulators are used in a variety of electronic components, including semiconductors, circuit boards, and connectors, where they help manage heat and prevent electrical failures. The increasing complexity and miniaturization of electronic devices require advanced insulation solutions that can provide reliable performance in high-temperature environments. High temperature wire insulators are essential for maintaining the efficiency and longevity of electronic systems, supporting the development of new technologies and innovations. Overall, the Global High Temperature Wire Insulators Market plays a crucial role in supporting the infrastructure and operations of these industries, providing the necessary insulation solutions to meet their specific needs and challenges.

Global High Temperature Wire Insulators Market Outlook:

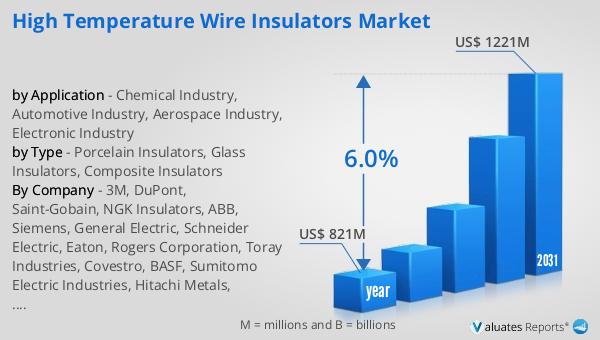

The outlook for the Global High Temperature Wire Insulators Market indicates a promising growth trajectory over the coming years. In 2024, the market was valued at approximately $821 million, reflecting its significant role in various high-demand industries. By 2031, it is anticipated that the market will expand to a revised size of $1,221 million. This growth is expected to occur at a compound annual growth rate (CAGR) of 6.0% during the forecast period. This upward trend is driven by several factors, including the increasing demand for high-performance insulation materials in industries such as automotive, aerospace, and electronics. As these industries continue to evolve and innovate, the need for reliable and durable insulation solutions becomes more critical. Additionally, the growing emphasis on energy efficiency and environmental sustainability is pushing manufacturers to develop advanced materials that can withstand extreme temperatures while minimizing energy loss. The market's expansion is also supported by technological advancements and the development of new materials that offer improved performance and versatility. As a result, the Global High Temperature Wire Insulators Market is poised to play a vital role in supporting the infrastructure and operations of modern technology and industry, providing the necessary insulation solutions to meet the evolving needs of various sectors.

| Report Metric | Details |

| Report Name | High Temperature Wire Insulators Market |

| Accounted market size in year | US$ 821 million |

| Forecasted market size in 2031 | US$ 1221 million |

| CAGR | 6.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | 3M, DuPont, Saint-Gobain, NGK Insulators, ABB, Siemens, General Electric, Schneider Electric, Eaton, Rogers Corporation, Toray Industries, Covestro, BASF, Sumitomo Electric Industries, Hitachi Metals, Mitsubishi Chemical, Toshiba Materials, Showa Denko |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |