What is Global Commercial Electric Heat Tracing Systems Market?

The Global Commercial Electric Heat Tracing Systems Market refers to the industry focused on the production and distribution of electric heat tracing systems used in various commercial applications. These systems are designed to maintain or raise the temperature of pipes, vessels, and other equipment. They are crucial in preventing freezing, ensuring the smooth flow of liquids, and maintaining process temperatures in industries such as oil and gas, chemical processing, and food and beverage. The market encompasses a range of products, including self-regulating, constant wattage, and mineral-insulated cables, each tailored to specific temperature requirements and environmental conditions. With the increasing demand for energy-efficient solutions and the need to comply with stringent safety regulations, the market for commercial electric heat tracing systems is witnessing significant growth. This growth is further fueled by technological advancements that enhance the efficiency and reliability of these systems, making them indispensable in modern industrial operations. As industries continue to expand globally, the demand for effective heat management solutions is expected to rise, driving the market forward.

Low Temperature: Up to 80 °C, Medium Temperature: Up to 110 °C, High Temperature: Up to 250 °C in the Global Commercial Electric Heat Tracing Systems Market:

In the Global Commercial Electric Heat Tracing Systems Market, temperature classifications play a crucial role in determining the appropriate system for specific applications. Low-temperature systems, which operate up to 80 °C, are typically used in applications where minimal heat is required to prevent freezing or maintain a stable temperature. These systems are ideal for maintaining the temperature of water pipes in cold climates or ensuring the smooth flow of viscous liquids in mild conditions. Medium-temperature systems, with an operational range up to 110 °C, are suited for more demanding applications where higher temperatures are necessary to maintain fluidity or prevent crystallization. These systems are often employed in chemical processing, where precise temperature control is essential to ensure product quality and process efficiency. High-temperature systems, capable of reaching up to 250 °C, are designed for the most demanding industrial applications. These systems are used in environments where extreme heat is required, such as in the oil and gas industry, where they help maintain the temperature of crude oil pipelines or prevent the solidification of heavy oils. The choice of temperature range is critical, as it directly impacts the efficiency, safety, and longevity of the heat tracing system. Each temperature classification requires specific materials and technologies to ensure optimal performance. For instance, low-temperature systems may utilize self-regulating cables that adjust their heat output based on ambient conditions, providing energy-efficient solutions for frost protection. Medium-temperature systems might employ constant wattage cables that deliver consistent heat output, ensuring uniform temperature maintenance across the entire length of the pipe or vessel. High-temperature systems often rely on mineral-insulated cables, which offer superior heat resistance and durability, making them suitable for harsh industrial environments. The selection of the appropriate temperature range and system type is influenced by various factors, including the nature of the fluid being transported, the environmental conditions, and the specific requirements of the application. Proper system design and installation are essential to ensure the effectiveness and reliability of the heat tracing solution. This involves careful consideration of factors such as heat loss calculations, insulation requirements, and power supply considerations. Additionally, regular maintenance and monitoring are crucial to ensure the continued performance and safety of the system. As industries continue to evolve and face new challenges, the demand for advanced heat tracing solutions that can operate across a wide range of temperatures is expected to grow. This will drive innovation and development in the market, leading to the introduction of new technologies and materials that enhance the efficiency, reliability, and sustainability of commercial electric heat tracing systems.

Petroleum, Chemical Industry, Electricity, Medicine, Ships, Other in the Global Commercial Electric Heat Tracing Systems Market:

The Global Commercial Electric Heat Tracing Systems Market finds extensive usage across various industries, each with unique requirements and challenges. In the petroleum industry, these systems are vital for maintaining the temperature of pipelines and storage tanks, preventing the solidification of crude oil and other petroleum products. This ensures the smooth flow of materials and reduces the risk of blockages, which can lead to costly downtime and maintenance. In the chemical industry, electric heat tracing systems are used to maintain precise temperatures in reactors, storage tanks, and pipelines, ensuring optimal reaction conditions and product quality. These systems help prevent crystallization and viscosity changes that can affect the efficiency and safety of chemical processes. The electricity sector also benefits from heat tracing systems, particularly in power plants where they are used to maintain the temperature of steam lines and prevent freezing in critical equipment. This ensures the reliable operation of power generation facilities and reduces the risk of equipment failure. In the medical field, heat tracing systems are used to maintain the temperature of fluids and gases in medical equipment, ensuring their safe and effective use. These systems are also employed in pharmaceutical manufacturing, where precise temperature control is essential for product quality and compliance with regulatory standards. The maritime industry relies on heat tracing systems to prevent freezing and maintain the temperature of fluids in ships, ensuring the safe and efficient operation of onboard systems. This is particularly important in cold climates, where freezing can pose significant risks to the safety and performance of vessels. Other industries, such as food and beverage, also utilize heat tracing systems to maintain the temperature of ingredients and products during processing and storage. This helps ensure product quality and safety, as well as compliance with food safety regulations. Overall, the versatility and effectiveness of commercial electric heat tracing systems make them indispensable across a wide range of industries. As these industries continue to grow and face new challenges, the demand for reliable and efficient heat tracing solutions is expected to increase, driving innovation and development in the market.

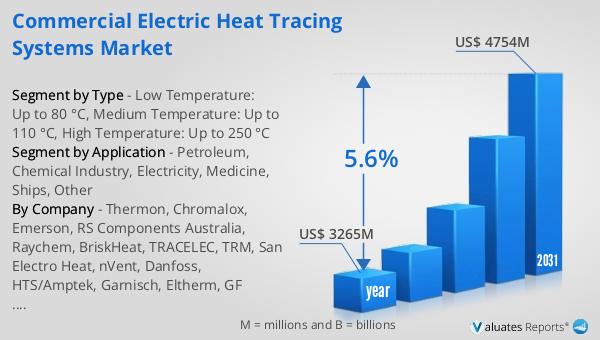

Global Commercial Electric Heat Tracing Systems Market Outlook:

The outlook for the Global Commercial Electric Heat Tracing Systems Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 3,265 million. By 2031, it is anticipated to expand to a revised size of around US$ 4,754 million, reflecting a compound annual growth rate (CAGR) of 5.6% over the forecast period. This growth is driven by several factors, including the increasing demand for energy-efficient solutions, the need for effective temperature management in various industries, and the ongoing expansion of industrial operations globally. The market's growth is also supported by technological advancements that enhance the efficiency, reliability, and sustainability of heat tracing systems. As industries continue to evolve and face new challenges, the demand for advanced heat tracing solutions that can operate across a wide range of temperatures is expected to grow. This will drive innovation and development in the market, leading to the introduction of new technologies and materials that enhance the efficiency, reliability, and sustainability of commercial electric heat tracing systems. The market's positive outlook reflects the critical role that these systems play in modern industrial operations, ensuring the safe and efficient management of temperature-sensitive processes.

| Report Metric | Details |

| Report Name | Commercial Electric Heat Tracing Systems Market |

| Accounted market size in year | US$ 3265 million |

| Forecasted market size in 2031 | US$ 4754 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Thermon, Chromalox, Emerson, RS Components Australia, Raychem, BriskHeat, TRACELEC, TRM, San Electro Heat, nVent, Danfoss, HTS/Amptek, Garnisch, Eltherm, GF Urecon, Flexelec, Fine Korea, Wuhu Jiahong New Material, Anhui Huanrui |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |