What is Global Ultra-high Vacuum Gate Valve Market?

The Global Ultra-high Vacuum Gate Valve Market is a specialized segment within the broader vacuum technology industry. These valves are crucial components used to control the flow of gases or liquids in systems that require ultra-high vacuum conditions. Such conditions are essential in various high-tech industries, including semiconductor manufacturing, space simulation, and scientific research, where even the slightest contamination can lead to significant issues. The market for these valves is driven by the increasing demand for advanced manufacturing processes and the need for precise control in vacuum environments. Ultra-high vacuum gate valves are designed to withstand extreme conditions and provide reliable sealing to maintain the integrity of the vacuum. They are typically made from high-grade materials like stainless steel and are engineered to offer long-lasting performance. As industries continue to push the boundaries of technology, the demand for these specialized valves is expected to grow, making them a critical component in the advancement of various high-tech applications. The market is characterized by a focus on innovation, with manufacturers continually developing new designs to meet the evolving needs of their customers.

Diameter Below 100mm, Diameter 100-300mm, Diameter Above 300mm in the Global Ultra-high Vacuum Gate Valve Market:

In the Global Ultra-high Vacuum Gate Valve Market, the size of the valve's diameter plays a significant role in its application and performance. Valves with a diameter below 100mm are typically used in applications where space is limited, and precision is paramount. These smaller valves are often found in laboratory settings, research facilities, and small-scale manufacturing processes where maintaining a high vacuum is crucial. Their compact size allows for easy integration into complex systems without compromising performance. On the other hand, valves with a diameter ranging from 100mm to 300mm are more versatile and are commonly used in medium-sized industrial applications. These valves strike a balance between size and performance, making them suitable for a wide range of uses, including semiconductor manufacturing and certain biopharmaceutical processes. They offer a good compromise between flow capacity and space requirements, making them a popular choice for many industries. Valves with a diameter above 300mm are designed for large-scale industrial applications where high flow rates are necessary. These valves are typically used in industries such as aerospace, large-scale manufacturing, and energy production, where maintaining an ultra-high vacuum over a large area is essential. The larger diameter allows for greater flow capacity, making them ideal for applications that require the movement of large volumes of gas or liquid. Each size category of ultra-high vacuum gate valves serves a specific purpose, and the choice of diameter depends on the specific requirements of the application. Manufacturers in this market are continually innovating to improve the performance and reliability of these valves, ensuring they meet the demanding needs of their customers. As technology advances and industries continue to evolve, the demand for ultra-high vacuum gate valves of all sizes is expected to grow, driven by the need for precise control and reliability in vacuum environments.

Electrical Industry, Biopharmaceutical, Semiconductor, Others in the Global Ultra-high Vacuum Gate Valve Market:

The Global Ultra-high Vacuum Gate Valve Market finds its usage across various industries, each with unique requirements and challenges. In the electrical industry, these valves are essential for processes that require a contamination-free environment. They are used in the manufacturing of components such as capacitors and insulators, where even the smallest impurity can affect performance. The ability of ultra-high vacuum gate valves to maintain a pristine environment makes them invaluable in ensuring the quality and reliability of electrical components. In the biopharmaceutical industry, maintaining a sterile environment is crucial for the production of drugs and vaccines. Ultra-high vacuum gate valves are used in processes such as freeze-drying and lyophilization, where maintaining a vacuum is essential to preserve the integrity of the products. These valves help ensure that the manufacturing process is free from contaminants, which is vital for the safety and efficacy of biopharmaceutical products. The semiconductor industry is another major user of ultra-high vacuum gate valves. The production of semiconductors requires an ultra-clean environment to prevent defects in the final product. These valves are used in various stages of semiconductor manufacturing, including deposition, etching, and ion implantation, where maintaining a high vacuum is critical. The precision and reliability of ultra-high vacuum gate valves make them indispensable in ensuring the quality and performance of semiconductor devices. Beyond these industries, ultra-high vacuum gate valves are also used in other applications such as space simulation, scientific research, and advanced manufacturing. In space simulation, these valves help create the vacuum conditions necessary to test spacecraft and components. In scientific research, they are used in experiments that require a controlled vacuum environment, such as particle physics and materials science. The versatility and reliability of ultra-high vacuum gate valves make them a vital component in a wide range of high-tech applications, driving their demand across various industries.

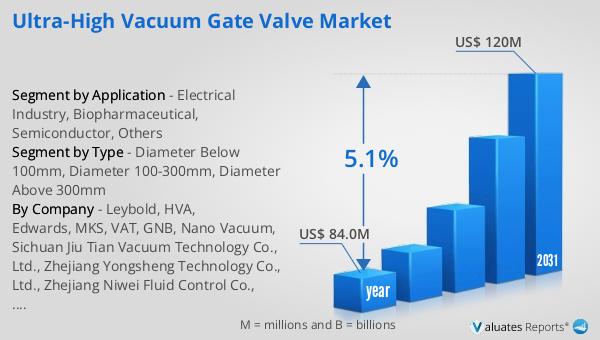

Global Ultra-high Vacuum Gate Valve Market Outlook:

The outlook for the Global Ultra-high Vacuum Gate Valve Market indicates a promising future. In 2024, the market was valued at approximately $84 million. By 2031, it is anticipated to expand to a revised size of $120 million, reflecting a compound annual growth rate (CAGR) of 5.1% over the forecast period. This growth is driven by the increasing demand for advanced manufacturing processes and the need for precise control in vacuum environments across various industries. As technology continues to advance, the need for ultra-high vacuum conditions becomes more critical, particularly in sectors such as semiconductor manufacturing, biopharmaceuticals, and aerospace. The market's expansion is also fueled by ongoing innovations in valve design and materials, which enhance performance and reliability. Manufacturers are continually developing new solutions to meet the evolving needs of their customers, ensuring that ultra-high vacuum gate valves remain a vital component in high-tech applications. The projected growth of the market underscores the importance of these valves in maintaining the integrity of vacuum environments and supporting the advancement of cutting-edge technologies. As industries continue to push the boundaries of what is possible, the demand for ultra-high vacuum gate valves is expected to grow, making them an essential part of the future of high-tech manufacturing and research.

| Report Metric | Details |

| Report Name | Ultra-high Vacuum Gate Valve Market |

| Accounted market size in year | US$ 84.0 million |

| Forecasted market size in 2031 | US$ 120 million |

| CAGR | 5.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Leybold, HVA, Edwards, MKS, VAT, GNB, Nano Vacuum, Sichuan Jiu Tian Vacuum Technology Co., Ltd., Zhejiang Yongsheng Technology Co., Ltd., Zhejiang Niwei Fluid Control Co., Ltd., Shanghai Gaochuan Valve Manufacturing Co., Ltd., Linyi Hanhai IoT Technology Co., Ltd., Shanghai Baoqiang Valve Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |