What is Global Boron Carbide Abrasive Compounds and Abrasive Slurries Market?

Global Boron Carbide Abrasive Compounds and Abrasive Slurries Market refers to the industry focused on the production and distribution of boron carbide-based abrasive materials. Boron carbide is a highly durable and hard material, making it ideal for abrasive applications. These compounds and slurries are used in various industries for grinding, polishing, and cutting hard materials. The market is driven by the demand for efficient and high-performance abrasives in sectors such as automotive, aerospace, and electronics. The unique properties of boron carbide, such as its hardness and thermal stability, make it a preferred choice for applications requiring precision and durability. As industries continue to seek advanced materials for improved performance and efficiency, the demand for boron carbide abrasive compounds and slurries is expected to grow. The market is characterized by ongoing research and development efforts to enhance the properties of these materials and expand their applications. Companies in this market are focused on innovation and developing new formulations to meet the evolving needs of their customers. The global market for boron carbide abrasive compounds and slurries is poised for growth as industries continue to prioritize high-quality and efficient abrasive solutions.

Abrasive Powder, Abrasive Paste in the Global Boron Carbide Abrasive Compounds and Abrasive Slurries Market:

Abrasive powders and pastes are integral components of the Global Boron Carbide Abrasive Compounds and Abrasive Slurries Market. Abrasive powders are fine particles of boron carbide that are used in various applications for grinding and polishing. These powders are available in different grades, depending on the size and hardness of the particles. The fine particles are ideal for precision applications, where a smooth and polished finish is required. Abrasive powders are used in industries such as electronics, where they are used to polish semiconductor wafers, and in the automotive industry, where they are used to polish engine components. The versatility of abrasive powders makes them a popular choice for a wide range of applications. Abrasive pastes, on the other hand, are a mixture of abrasive powders and a liquid binder. The paste form allows for easy application and control during the polishing process. Abrasive pastes are used in applications where a more controlled and uniform finish is required. They are commonly used in the finishing of metal surfaces, where a high degree of precision is required. The paste form allows for easy application and control, making it ideal for use in automated polishing systems. The use of abrasive pastes is common in the aerospace industry, where they are used to polish turbine blades and other critical components. The combination of abrasive powders and pastes in the Global Boron Carbide Abrasive Compounds and Abrasive Slurries Market provides a comprehensive solution for a wide range of abrasive applications. The market is driven by the demand for high-performance abrasives that can deliver precise and efficient results. As industries continue to seek advanced materials for improved performance and efficiency, the demand for abrasive powders and pastes is expected to grow. Companies in this market are focused on innovation and developing new formulations to meet the evolving needs of their customers. The global market for abrasive powders and pastes is poised for growth as industries continue to prioritize high-quality and efficient abrasive solutions.

Grind, Drilling, Other in the Global Boron Carbide Abrasive Compounds and Abrasive Slurries Market:

The Global Boron Carbide Abrasive Compounds and Abrasive Slurries Market finds extensive usage in various applications, including grinding, drilling, and other specialized processes. In grinding, boron carbide abrasive compounds are used to achieve precise and smooth finishes on hard materials. The hardness and durability of boron carbide make it ideal for grinding applications, where it can efficiently remove material and create a polished surface. This is particularly important in industries such as automotive and aerospace, where precision and quality are paramount. In drilling, boron carbide abrasive slurries are used to enhance the efficiency and precision of the drilling process. The abrasive properties of boron carbide allow for faster and more accurate drilling, reducing the time and effort required to achieve the desired results. This is especially beneficial in industries such as oil and gas, where drilling efficiency is critical. In addition to grinding and drilling, boron carbide abrasive compounds and slurries are used in a variety of other applications. These include cutting, polishing, and finishing processes, where the unique properties of boron carbide provide superior performance and results. The versatility of boron carbide abrasives makes them a valuable tool in a wide range of industries, from electronics to construction. As industries continue to seek advanced materials for improved performance and efficiency, the demand for boron carbide abrasive compounds and slurries is expected to grow. Companies in this market are focused on innovation and developing new formulations to meet the evolving needs of their customers. The global market for boron carbide abrasive compounds and slurries is poised for growth as industries continue to prioritize high-quality and efficient abrasive solutions.

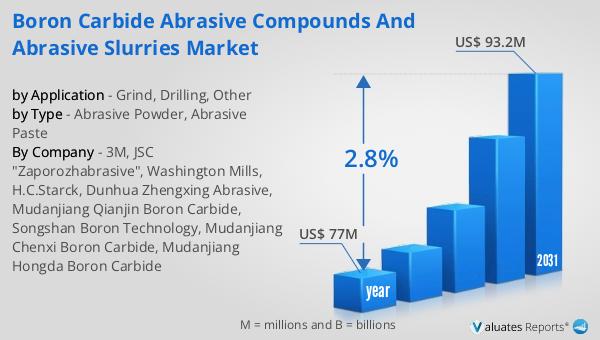

Global Boron Carbide Abrasive Compounds and Abrasive Slurries Market Outlook:

The global market for Boron Carbide Abrasive Compounds and Abrasive Slurries was valued at $77 million in 2024 and is anticipated to expand to a revised size of $93.2 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.8% over the forecast period. This growth trajectory underscores the increasing demand for high-performance abrasive solutions across various industries. The market's expansion is driven by the unique properties of boron carbide, which include exceptional hardness and thermal stability, making it an ideal choice for applications requiring precision and durability. As industries such as automotive, aerospace, and electronics continue to evolve and demand more efficient and effective materials, the need for boron carbide abrasive compounds and slurries is expected to rise. Companies operating in this market are focusing on innovation and the development of new formulations to meet the changing needs of their customers. The global market for boron carbide abrasive compounds and slurries is set to grow as industries prioritize high-quality and efficient abrasive solutions. This growth is indicative of the broader trend towards advanced materials that offer superior performance and efficiency, ensuring that boron carbide remains a critical component in the global abrasives market.

| Report Metric | Details |

| Report Name | Boron Carbide Abrasive Compounds and Abrasive Slurries Market |

| Accounted market size in year | US$ 77 million |

| Forecasted market size in 2031 | US$ 93.2 million |

| CAGR | 2.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | 3M, JSC "Zaporozhabrasive", Washington Mills, H.C.Starck, Dunhua Zhengxing Abrasive, Mudanjiang Qianjin Boron Carbide, Songshan Boron Technology, Mudanjiang Chenxi Boron Carbide, Mudanjiang Hongda Boron Carbide |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |