What is Global Permanent Stainless Steel Cathode Plate Market?

The Global Permanent Stainless Steel Cathode Plate Market is a specialized segment within the broader industrial materials market, focusing on the production and distribution of stainless steel cathode plates. These plates are essential components in various industrial processes, particularly in the electro-winning and electro-refining of metals. Stainless steel cathode plates are favored for their durability, corrosion resistance, and ability to withstand harsh chemical environments, making them ideal for use in industries such as metallurgy, chemical processing, and energy production. The market is driven by the increasing demand for efficient and sustainable metal extraction processes, as well as the growing need for high-quality materials in industrial applications. As industries continue to prioritize sustainability and efficiency, the demand for permanent stainless steel cathode plates is expected to rise, further fueling market growth. The market is characterized by a diverse range of products, catering to different industrial needs and specifications, with manufacturers focusing on innovation and quality to maintain a competitive edge. Overall, the Global Permanent Stainless Steel Cathode Plate Market plays a crucial role in supporting industrial operations worldwide, contributing to the advancement of various sectors through its reliable and high-performance products.

Thickness 1-3mm, Thickness 3-5mm, Other in the Global Permanent Stainless Steel Cathode Plate Market:

In the Global Permanent Stainless Steel Cathode Plate Market, the thickness of the plates is a critical factor that influences their application and performance. Plates with a thickness of 1-3mm are typically used in applications where flexibility and ease of handling are important. These thinner plates are often employed in industries where space constraints and weight considerations are paramount, such as in certain chemical processing applications or in smaller-scale metallurgy operations. The reduced thickness allows for easier installation and integration into existing systems, making them a popular choice for industries looking to optimize their processes without compromising on quality or performance. On the other hand, plates with a thickness of 3-5mm are designed for more demanding applications where additional strength and durability are required. These thicker plates are commonly used in heavy-duty industrial processes, such as large-scale metal extraction and refining operations, where they must withstand high levels of stress and corrosive environments. The increased thickness provides enhanced structural integrity, ensuring that the plates can endure the rigors of continuous use in harsh conditions. Additionally, the thicker plates offer improved longevity, reducing the need for frequent replacements and maintenance, which can be a significant cost-saving factor for industries. Beyond these standard thickness categories, the market also offers other variations to meet specific industrial requirements. These may include custom thicknesses tailored to unique applications or specialized coatings and treatments to enhance performance in particular environments. For instance, some industries may require plates with additional surface treatments to improve their resistance to specific chemicals or to enhance their conductivity for certain electrochemical processes. The availability of these customized options allows industries to select the most suitable cathode plates for their specific needs, ensuring optimal performance and efficiency. Manufacturers in the Global Permanent Stainless Steel Cathode Plate Market are continually innovating to develop new products that meet the evolving demands of their customers. This includes exploring new materials and manufacturing techniques to produce plates with improved properties, such as increased corrosion resistance, enhanced conductivity, and greater mechanical strength. By offering a diverse range of products, the market caters to a wide array of industrial applications, supporting the growth and development of various sectors. Overall, the thickness of stainless steel cathode plates is a key consideration for industries looking to optimize their processes and achieve the best possible outcomes. Whether it's the flexibility and ease of use offered by thinner plates or the strength and durability provided by thicker options, the Global Permanent Stainless Steel Cathode Plate Market offers solutions to meet the diverse needs of its customers.

Chemical, Metallurgy, Electricity, Aerospace, Other in the Global Permanent Stainless Steel Cathode Plate Market:

The Global Permanent Stainless Steel Cathode Plate Market finds extensive usage across various industries, including chemical, metallurgy, electricity, aerospace, and others, due to its exceptional properties and versatility. In the chemical industry, stainless steel cathode plates are utilized in processes that involve harsh chemicals and corrosive environments. Their corrosion resistance and durability make them ideal for applications such as electrochemical reactions, where they serve as a stable and reliable component. The plates' ability to withstand aggressive chemical agents ensures long-term performance and reduces the risk of contamination, which is crucial in maintaining the purity and quality of chemical products. In the metallurgy sector, stainless steel cathode plates play a vital role in the electro-winning and electro-refining of metals. These processes require materials that can endure high temperatures and corrosive conditions, making stainless steel an excellent choice. The plates facilitate the efficient extraction and purification of metals, contributing to the production of high-quality metal products. Their robustness and longevity also minimize downtime and maintenance costs, enhancing the overall efficiency of metallurgical operations. The electricity industry benefits from the use of stainless steel cathode plates in various applications, including energy storage and conversion systems. Their excellent conductivity and resistance to corrosion make them suitable for use in batteries, fuel cells, and other energy-related technologies. The plates' ability to maintain performance over extended periods ensures the reliability and efficiency of electrical systems, supporting the growing demand for sustainable and renewable energy solutions. In the aerospace industry, stainless steel cathode plates are used in applications that require materials with high strength-to-weight ratios and resistance to extreme conditions. Their durability and corrosion resistance make them suitable for use in aircraft components and systems, where they contribute to the safety and performance of aerospace technologies. The plates' ability to withstand high temperatures and corrosive environments ensures their reliability in demanding aerospace applications, supporting the industry's focus on innovation and advancement. Beyond these specific industries, stainless steel cathode plates are also used in various other applications, including water treatment, food processing, and construction. Their versatility and adaptability make them a valuable component in a wide range of industrial processes, contributing to the efficiency and sustainability of operations across different sectors. Overall, the Global Permanent Stainless Steel Cathode Plate Market plays a crucial role in supporting the growth and development of various industries through its high-performance and reliable products. The plates' exceptional properties and versatility make them an indispensable component in numerous applications, driving innovation and efficiency in industrial processes worldwide.

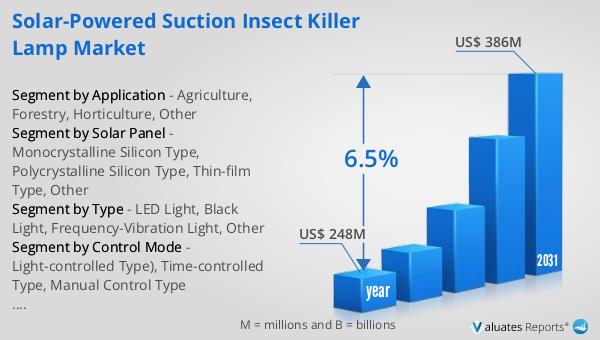

Global Permanent Stainless Steel Cathode Plate Market Outlook:

The outlook for the Global Permanent Stainless Steel Cathode Plate Market indicates a promising future, with the market valued at approximately US$ 319 million in 2024. It is anticipated to grow steadily, reaching an estimated size of US$ 423 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 4.0% over the forecast period. The market's expansion is driven by the increasing demand for high-quality and durable materials in various industrial applications. As industries continue to prioritize efficiency and sustainability, the need for reliable and long-lasting components like stainless steel cathode plates is expected to rise. The market's growth is also supported by advancements in manufacturing technologies and the development of innovative products that cater to the evolving needs of different sectors. Manufacturers are focusing on enhancing the properties of stainless steel cathode plates, such as improving their corrosion resistance, conductivity, and mechanical strength, to meet the specific requirements of their customers. This focus on innovation and quality is crucial in maintaining a competitive edge in the market and ensuring long-term growth. Overall, the Global Permanent Stainless Steel Cathode Plate Market is poised for significant growth, driven by the increasing demand for high-performance materials and the continuous advancement of industrial technologies.

| Report Metric | Details |

| Report Name | Permanent Stainless Steel Cathode Plate Market |

| Accounted market size in year | US$ 319 million |

| Forecasted market size in 2031 | US$ 423 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Alliance Manufacturing, Glencore Technology, Limpact, Sanyou Technology, AATi, Tongling Huilpu Technology, Tianxin Metallurgical Equipment Technology, Metso, Yunnan Daze Electrode Technology, Kunming Hendera Science and Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |