What is Global Zinc Stearate Dispersion Market?

The Global Zinc Stearate Dispersion Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of zinc stearate in a dispersed form. Zinc stearate is a compound made from zinc and stearic acid, known for its lubricating properties and water-repellent characteristics. In its dispersed form, it is used in various industrial applications, including plastics, rubber, and coatings, due to its ability to improve texture, enhance product stability, and act as a release agent. The market for zinc stearate dispersion is driven by its demand in manufacturing processes where it serves as a critical component in ensuring product quality and efficiency. As industries continue to expand and innovate, the need for high-performance materials like zinc stearate dispersion grows, making it an essential part of the supply chain in sectors such as automotive, construction, and consumer goods. The market's growth is also influenced by technological advancements and the increasing emphasis on sustainable and environmentally friendly production methods. Overall, the Global Zinc Stearate Dispersion Market plays a crucial role in supporting industrial operations and contributing to the development of high-quality products across various sectors.

30% Purity, 45% Purity, Other in the Global Zinc Stearate Dispersion Market:

In the Global Zinc Stearate Dispersion Market, purity levels such as 30% and 45% are significant as they determine the concentration of zinc stearate in the dispersion, impacting its effectiveness and suitability for different applications. The 30% purity zinc stearate dispersion is often used in applications where a moderate level of lubrication and water repellency is required. This level of purity is suitable for industries like rubber manufacturing, where it acts as a release agent and helps in the smooth removal of products from molds. It also finds use in the production of certain types of plastics, where it aids in improving the texture and finish of the final product. The 30% purity level strikes a balance between performance and cost, making it an attractive option for manufacturers looking to optimize their production processes without incurring excessive expenses. On the other hand, the 45% purity zinc stearate dispersion offers a higher concentration of zinc stearate, providing enhanced performance characteristics. This level of purity is particularly beneficial in applications that demand superior lubrication and water repellency, such as in the coatings and paints industry. In these applications, the higher purity dispersion helps in achieving a smoother finish, better adhesion, and increased durability of the coatings. Additionally, the 45% purity dispersion is used in the production of high-performance plastics and rubber products, where its superior properties contribute to the overall quality and longevity of the products. The choice between 30% and 45% purity levels depends on the specific requirements of the application, with manufacturers selecting the appropriate concentration based on factors such as desired performance, cost considerations, and environmental impact. Beyond the standard 30% and 45% purity levels, the Global Zinc Stearate Dispersion Market also includes other variations that cater to niche applications and specialized industries. These variations may involve different formulations or additives that enhance specific properties of the dispersion, such as increased thermal stability or improved compatibility with certain materials. For instance, some formulations are designed to meet the stringent requirements of the pharmaceutical and food industries, where the dispersion must adhere to strict safety and quality standards. In these cases, the zinc stearate dispersion may be modified to ensure it is free from contaminants and meets regulatory guidelines. Other variations may be tailored for use in the electronics industry, where the dispersion's properties are optimized for use in the production of electronic components and devices. The availability of different purity levels and formulations within the Global Zinc Stearate Dispersion Market allows manufacturers to select the most suitable product for their specific needs, ensuring optimal performance and efficiency in their operations. As the market continues to evolve, the development of new and innovative zinc stearate dispersion products is expected to further expand the range of applications and drive growth in this dynamic industry.

Architecture, Papermaking, Other in the Global Zinc Stearate Dispersion Market:

The Global Zinc Stearate Dispersion Market finds extensive usage in various sectors, including architecture, papermaking, and other industries, due to its versatile properties and ability to enhance product performance. In the field of architecture, zinc stearate dispersion is primarily used in coatings and paints to improve their durability, water resistance, and finish. The dispersion acts as a lubricant and release agent, ensuring a smooth application and preventing defects such as cracking or peeling. This makes it an essential component in architectural coatings, where aesthetics and longevity are critical. Additionally, zinc stearate dispersion is used in the production of construction materials such as sealants and adhesives, where it enhances the material's performance by improving its texture and adhesion properties. In the papermaking industry, zinc stearate dispersion plays a crucial role in the production of high-quality paper products. It is used as a coating agent to improve the paper's surface properties, such as smoothness, gloss, and printability. The dispersion helps in achieving a uniform coating, which enhances the paper's appearance and performance in printing applications. Furthermore, zinc stearate dispersion is used as a lubricant in the papermaking process, reducing friction and wear on machinery, thereby increasing efficiency and reducing maintenance costs. This makes it an invaluable component in the production of various types of paper, including coated paper, specialty paper, and packaging materials. Beyond architecture and papermaking, zinc stearate dispersion is utilized in a wide range of other industries, each benefiting from its unique properties. In the plastics industry, it is used as a release agent and lubricant, facilitating the smooth removal of molded products and improving their surface finish. This is particularly important in the production of high-performance plastics used in automotive, electronics, and consumer goods. In the rubber industry, zinc stearate dispersion is used to prevent sticking and improve the flow of rubber compounds during processing, enhancing the quality and consistency of the final product. Additionally, zinc stearate dispersion is used in the production of cosmetics and personal care products, where it acts as a thickening agent and improves the texture and stability of formulations. Its non-toxic and non-irritating properties make it suitable for use in products such as creams, lotions, and powders. The versatility and effectiveness of zinc stearate dispersion make it a valuable component in a wide range of applications, contributing to the development of high-quality products across various industries. As the demand for innovative and sustainable materials continues to grow, the Global Zinc Stearate Dispersion Market is expected to play an increasingly important role in supporting industrial operations and driving advancements in product performance and quality.

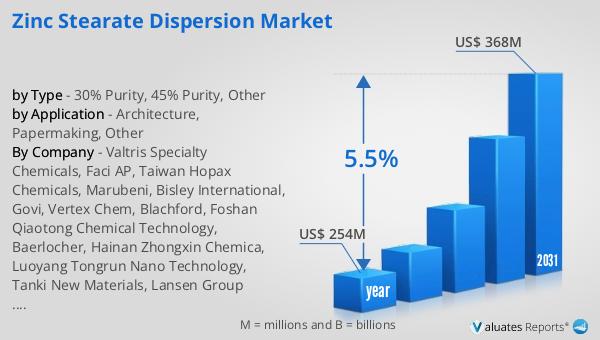

Global Zinc Stearate Dispersion Market Outlook:

The outlook for the Global Zinc Stearate Dispersion Market indicates a promising growth trajectory over the coming years. In 2024, the market was valued at approximately US$ 254 million, reflecting its significant role in various industrial applications. As industries continue to expand and innovate, the demand for zinc stearate dispersion is expected to rise, driven by its versatile properties and ability to enhance product performance. By 2031, the market is projected to reach a revised size of US$ 368 million, growing at a compound annual growth rate (CAGR) of 5.5% during the forecast period. This growth can be attributed to several factors, including the increasing demand for high-performance materials in sectors such as automotive, construction, and consumer goods. Additionally, advancements in technology and the development of new and innovative zinc stearate dispersion products are expected to further drive market growth. The emphasis on sustainable and environmentally friendly production methods is also likely to contribute to the market's expansion, as manufacturers seek to optimize their processes and reduce their environmental impact. Overall, the Global Zinc Stearate Dispersion Market is poised for significant growth, supported by its critical role in enhancing product quality and efficiency across various industries.

| Report Metric | Details |

| Report Name | Zinc Stearate Dispersion Market |

| Accounted market size in year | US$ 254 million |

| Forecasted market size in 2031 | US$ 368 million |

| CAGR | 5.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Valtris Specialty Chemicals, Faci AP, Taiwan Hopax Chemicals, Marubeni, Bisley International, Govi, Vertex Chem, Blachford, Foshan Qiaotong Chemical Technology, Baerlocher, Hainan Zhongxin Chemica, Luoyang Tongrun Nano Technology, Tanki New Materials, Lansen Group International, Peter Greven |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |