What is Global Solid State Relays for Industrial Market?

Global Solid State Relays (SSRs) for the industrial market are electronic switching devices that use semiconductor properties to switch on or off without any moving parts. Unlike traditional electromechanical relays, SSRs offer faster switching times, longer lifespan, and greater reliability due to the absence of mechanical components. These relays are crucial in industrial applications where precision and durability are paramount. They are used to control various electrical loads, such as motors, heaters, and lights, by providing isolation between the control signal and the load. This isolation is essential for protecting sensitive control circuits from high voltages and currents. SSRs are particularly favored in environments where noise reduction and minimal electromagnetic interference are required. Their compact size and ability to handle high-frequency operations make them ideal for modern industrial automation systems. As industries continue to evolve with advancements in technology, the demand for efficient and reliable switching solutions like SSRs is expected to grow, making them a vital component in the industrial sector. The global market for these relays is driven by the need for energy-efficient solutions and the increasing automation across various industries.

AC Out SSR, DC Out SSR in the Global Solid State Relays for Industrial Market:

AC Output Solid State Relays (SSR) and DC Output SSRs are two primary types of solid-state relays used in the industrial market, each serving distinct purposes based on their output characteristics. AC Output SSRs are designed to control AC loads, making them suitable for applications where alternating current is prevalent. These relays are commonly used in industrial settings to manage devices such as AC motors, lighting systems, and heating elements. The key advantage of AC Output SSRs is their ability to handle high voltage and current levels, providing robust performance in demanding environments. They operate silently and are resistant to mechanical wear and tear, which enhances their longevity and reliability. Additionally, AC Output SSRs offer zero-crossing switching, which minimizes electrical noise and reduces the risk of voltage spikes, ensuring smooth operation of connected devices. On the other hand, DC Output SSRs are tailored for applications involving direct current. These relays are essential in industries where DC-powered equipment is prevalent, such as in battery-operated systems, solar power installations, and certain types of industrial machinery. DC Output SSRs provide precise control over DC loads, offering rapid switching capabilities that are crucial for applications requiring quick response times. They are also known for their ability to handle high-frequency operations, making them ideal for modern automation systems. One of the significant benefits of DC Output SSRs is their ability to provide consistent performance in environments with fluctuating power conditions. This reliability is particularly important in industries where uninterrupted operation is critical. Both AC and DC Output SSRs contribute to the overall efficiency and safety of industrial processes by providing reliable and precise control over electrical loads. Their solid-state design ensures minimal maintenance requirements, reducing downtime and operational costs. As industries continue to embrace automation and energy-efficient solutions, the demand for both AC and DC Output SSRs is expected to rise, driven by the need for reliable and efficient switching solutions. The global market for these relays is characterized by continuous innovation, with manufacturers focusing on enhancing performance, durability, and integration capabilities to meet the evolving needs of industrial applications.

General Industrial, Precision Industrial in the Global Solid State Relays for Industrial Market:

In the realm of industrial applications, Global Solid State Relays (SSRs) play a pivotal role in both general and precision industrial sectors. In general industrial applications, SSRs are widely used to control various types of machinery and equipment. Their ability to handle high power loads and provide reliable switching makes them indispensable in environments where heavy-duty operations are conducted. For instance, in manufacturing plants, SSRs are used to control conveyor belts, pumps, and large-scale heating systems. Their robust design ensures that they can withstand harsh industrial conditions, including high temperatures and vibrations, without compromising performance. Moreover, SSRs contribute to energy efficiency by minimizing power losses during switching operations, which is crucial in industries aiming to reduce operational costs and environmental impact. In precision industrial applications, SSRs are equally vital, albeit for different reasons. Precision industries, such as semiconductor manufacturing, require highly accurate and reliable control systems to ensure product quality and process efficiency. SSRs provide the precision needed for these applications by offering rapid switching capabilities and minimal signal distortion. This precision is essential in processes where even the slightest deviation can lead to significant defects or inefficiencies. Additionally, SSRs' ability to operate silently and without mechanical wear makes them ideal for cleanroom environments, where contamination from mechanical components must be avoided. The use of SSRs in precision industries also extends to applications such as laser cutting, where precise control over power delivery is crucial for achieving desired results. Overall, the versatility and reliability of SSRs make them a cornerstone in both general and precision industrial applications. Their ability to provide efficient and precise control over electrical loads ensures that industrial processes run smoothly and efficiently, contributing to increased productivity and reduced operational costs. As industries continue to evolve and demand more sophisticated control solutions, the role of SSRs in the industrial market is expected to grow, driven by the need for reliable, efficient, and precise switching technologies.

Global Solid State Relays for Industrial Market Outlook:

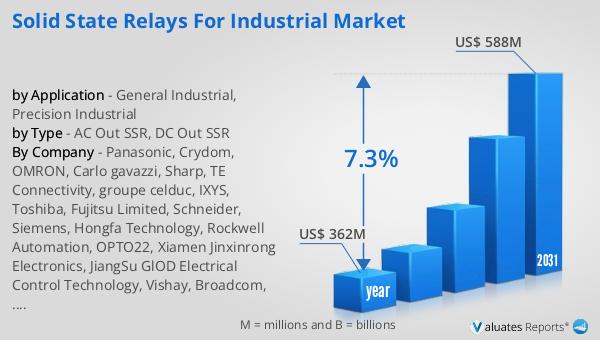

The global market for Solid State Relays in the industrial sector was valued at $362 million in 2024, with projections indicating a growth to $588 million by 2031. This growth represents a compound annual growth rate (CAGR) of 7.3% over the forecast period. The increasing demand for SSRs is driven by the need for reliable and efficient switching solutions in various industrial applications. As industries continue to embrace automation and energy-efficient technologies, the demand for SSRs is expected to rise. These relays offer numerous advantages over traditional electromechanical relays, including faster switching times, longer lifespan, and greater reliability. Their ability to handle high power loads and provide precise control over electrical systems makes them indispensable in modern industrial settings. Furthermore, the growing focus on reducing operational costs and minimizing environmental impact is driving the adoption of SSRs, as they contribute to energy efficiency and reduced power losses. The market is characterized by continuous innovation, with manufacturers focusing on enhancing performance, durability, and integration capabilities to meet the evolving needs of industrial applications. As the global market for SSRs continues to expand, it presents significant opportunities for manufacturers and suppliers to capitalize on the growing demand for reliable and efficient switching solutions.

| Report Metric | Details |

| Report Name | Solid State Relays for Industrial Market |

| Accounted market size in year | US$ 362 million |

| Forecasted market size in 2031 | US$ 588 million |

| CAGR | 7.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Panasonic, Crydom, OMRON, Carlo gavazzi, Sharp, TE Connectivity, groupe celduc, IXYS, Toshiba, Fujitsu Limited, Schneider, Siemens, Hongfa Technology, Rockwell Automation, OPTO22, Xiamen Jinxinrong Electronics, JiangSu GlOD Electrical Control Technology, Vishay, Broadcom, Clion Electric, Bright Toward, Wuxi Tianhao Electronics, Shaanxi Qunli, Zhejiang Chint Electrics, Wuxi Solid, COSMO, Suzhou Integrated Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |