What is Global Urethane Resin for PU Synthetic Leather Market?

The Global Urethane Resin for PU Synthetic Leather Market is a significant segment within the synthetic leather industry, focusing on the production and application of urethane resins. These resins are essential components in creating polyurethane (PU) synthetic leather, a versatile and widely used material that mimics the look and feel of genuine leather. PU synthetic leather is favored for its durability, flexibility, and cost-effectiveness, making it a popular choice across various industries. The market for urethane resin is driven by the increasing demand for synthetic leather in applications such as automotive interiors, furniture, footwear, garments, and accessories. As consumers and manufacturers seek sustainable and animal-friendly alternatives to genuine leather, the demand for high-quality PU synthetic leather continues to rise. This market is characterized by ongoing innovations in resin formulations to enhance the performance and environmental sustainability of synthetic leather products. With advancements in technology and growing awareness of eco-friendly materials, the Global Urethane Resin for PU Synthetic Leather Market is poised for significant growth, catering to the evolving needs of industries and consumers worldwide.

Resin for Dry Process, Resin for Wet Process in the Global Urethane Resin for PU Synthetic Leather Market:

In the Global Urethane Resin for PU Synthetic Leather Market, the resin used in the dry process and wet process plays a crucial role in determining the quality and characteristics of the final synthetic leather product. The dry process involves the application of urethane resin onto a release paper or fabric substrate, which is then cured to form a solid film. This method is known for producing synthetic leather with a smooth and uniform surface, making it ideal for applications where aesthetics and texture are important. The resin used in the dry process is typically designed to provide excellent adhesion, flexibility, and resistance to wear and tear. On the other hand, the wet process involves the impregnation of a fabric substrate with a urethane resin solution, followed by coagulation and drying. This method results in synthetic leather with a more porous and breathable structure, making it suitable for applications where comfort and breathability are prioritized, such as in footwear and garments. The resin used in the wet process is formulated to ensure optimal penetration and bonding with the fabric substrate, providing durability and resistance to environmental factors. Both processes require precise control over the resin formulation and application parameters to achieve the desired properties in the final product. The choice between dry and wet processes depends on the specific requirements of the end-use application, with manufacturers often selecting the method that best aligns with their product goals and consumer preferences. As the demand for PU synthetic leather continues to grow, innovations in resin technology are expected to enhance the performance and sustainability of both dry and wet process synthetic leather, offering improved options for various industries.

Automobile Interior, Furniture, Shoes, Garment, Bags, Other in the Global Urethane Resin for PU Synthetic Leather Market:

The Global Urethane Resin for PU Synthetic Leather Market finds extensive usage across several key areas, including automobile interiors, furniture, shoes, garments, bags, and other applications. In the automotive industry, PU synthetic leather is widely used for car seats, dashboards, and door panels due to its durability, ease of maintenance, and aesthetic appeal. The urethane resin used in these applications ensures that the synthetic leather can withstand the rigors of daily use, including exposure to sunlight, temperature fluctuations, and wear and tear. In the furniture industry, PU synthetic leather is a popular choice for upholstery, offering a cost-effective and stylish alternative to genuine leather. The resin provides the necessary flexibility and strength to ensure that the furniture remains comfortable and visually appealing over time. In the footwear industry, PU synthetic leather is used for making shoes that are not only fashionable but also comfortable and durable. The resin used in this application ensures that the synthetic leather can withstand the stresses of walking and running, providing long-lasting performance. In the garment industry, PU synthetic leather is used to create stylish and trendy clothing items, offering a cruelty-free alternative to animal leather. The resin provides the necessary softness and flexibility to ensure that the garments are comfortable to wear. In the production of bags and accessories, PU synthetic leather is favored for its versatility and ability to mimic the look and feel of genuine leather. The urethane resin used in these applications ensures that the synthetic leather is strong enough to carry heavy loads while maintaining its aesthetic appeal. Other applications of PU synthetic leather include its use in the production of belts, wallets, and other fashion accessories, where the resin provides the necessary durability and resistance to wear and tear. As consumer preferences shift towards sustainable and animal-friendly materials, the demand for PU synthetic leather in these areas is expected to continue growing, driven by innovations in urethane resin technology that enhance the performance and environmental sustainability of the products.

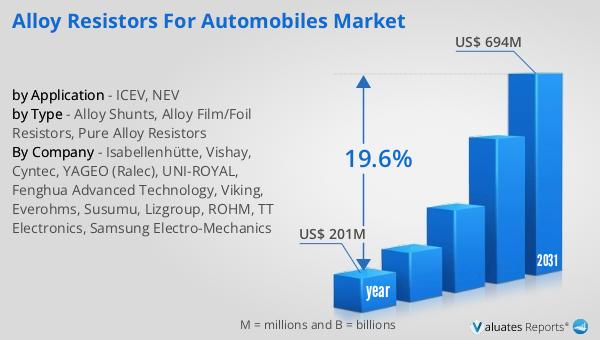

Global Urethane Resin for PU Synthetic Leather Market Outlook:

The outlook for the Global Urethane Resin for PU Synthetic Leather Market is promising, with significant growth anticipated in the coming years. In 2024, the market was valued at approximately US$ 9,487 million, reflecting the strong demand for urethane resin in the production of PU synthetic leather. This demand is driven by the increasing preference for synthetic leather across various industries, including automotive, furniture, footwear, and fashion. As manufacturers and consumers alike seek sustainable and cost-effective alternatives to genuine leather, the market for urethane resin is expected to expand significantly. By 2031, the market is projected to reach a revised size of US$ 33,430 million, growing at a compound annual growth rate (CAGR) of 20.0% during the forecast period. This impressive growth rate underscores the market's potential and the increasing adoption of PU synthetic leather in diverse applications. The expansion of the market is also supported by ongoing innovations in resin formulations, which aim to enhance the performance, durability, and environmental sustainability of synthetic leather products. As the market continues to evolve, stakeholders are likely to focus on developing advanced resin technologies that meet the changing needs of industries and consumers, ensuring the continued growth and success of the Global Urethane Resin for PU Synthetic Leather Market.

| Report Metric | Details |

| Report Name | Urethane Resin for PU Synthetic Leather Market |

| Accounted market size in year | US$ 9487 million |

| Forecasted market size in 2031 | US$ 33430 million |

| CAGR | 20.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ADEKA CORPORATION, Polynt S.p.A, Wacker Chemie, SEKISUI CHEMICAL CO.,LTD., SAPICI S.p.A., Silvateam S.p.a, Arkema, Coim Group, DIC Corporation, UBE Corporation, Covestro AG, Smooth-On,Inc., Capital Resin Corporation, NICCA CHEMICAL CO.,LTD., TOYOPOLYMER CO.,LTD., KANGNAM JEVISCO CO.,LTD, Berkshire Hathaway, SANYO CHEMICAL INDUSTRIES,LTD, Hanwha Solutions Chemical Division, Shanghai Huide Science and Technology Co.,ltd., XUCHUAN CHEMICAL(SUZHOU) CO.,LTD, Huafon Chemical Co.,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |