What is Global Alloy Resistors for Automobiles Market?

The Global Alloy Resistors for Automobiles Market is a specialized segment within the automotive industry that focuses on the production and application of alloy resistors. These resistors are crucial components in modern vehicles, playing a significant role in managing electrical currents and ensuring the efficient operation of various automotive systems. As vehicles become more technologically advanced, the demand for reliable and efficient electrical components like alloy resistors has increased. This market encompasses a range of resistor types, including alloy shunts, alloy film/foil resistors, and pure alloy resistors, each serving specific functions within a vehicle's electrical system. The growth of this market is driven by the increasing complexity of automotive electronics, the rise of electric and hybrid vehicles, and the ongoing need for improved fuel efficiency and reduced emissions. As a result, manufacturers are continually innovating to produce resistors that meet the evolving needs of the automotive industry, ensuring that vehicles remain safe, efficient, and environmentally friendly. The Global Alloy Resistors for Automobiles Market is poised for significant growth as the automotive industry continues to evolve and embrace new technologies.

Alloy Shunts, Alloy Film/Foil Resistors, Pure Alloy Resistors in the Global Alloy Resistors for Automobiles Market:

Alloy shunts, alloy film/foil resistors, and pure alloy resistors are integral components of the Global Alloy Resistors for Automobiles Market, each serving distinct roles in automotive applications. Alloy shunts are primarily used for current sensing and measurement in vehicles. They are designed to handle high currents and provide accurate readings, which are essential for monitoring and controlling various electrical systems within a vehicle. These shunts are typically made from materials like manganin or constantan, which offer low temperature coefficients and high stability, ensuring precise measurements even under varying environmental conditions. Alloy film/foil resistors, on the other hand, are known for their precision and reliability. They are used in applications where accuracy is paramount, such as in engine control units and other critical automotive systems. These resistors are constructed by depositing a thin layer of alloy onto a substrate, allowing for tight tolerance and low noise operation. The use of alloy film/foil resistors is particularly important in modern vehicles, where electronic systems are becoming increasingly complex and require components that can maintain performance over time. Pure alloy resistors are another key component in this market, offering high power handling capabilities and excellent thermal performance. These resistors are often used in power electronics and other high-stress applications within a vehicle, where they must withstand significant electrical and thermal loads. The choice of alloy materials in these resistors is crucial, as it determines their performance characteristics and suitability for specific applications. As the automotive industry continues to evolve, the demand for advanced alloy resistors is expected to grow, driven by the need for more efficient and reliable electrical systems. Manufacturers are investing in research and development to create resistors that meet the stringent requirements of modern vehicles, ensuring that they can operate effectively in a wide range of conditions. This focus on innovation and quality is essential for the continued growth and success of the Global Alloy Resistors for Automobiles Market.

ICEV, NEV in the Global Alloy Resistors for Automobiles Market:

The usage of Global Alloy Resistors for Automobiles Market in Internal Combustion Engine Vehicles (ICEV) and New Energy Vehicles (NEV) highlights the versatility and importance of these components in different automotive contexts. In ICEVs, alloy resistors are used extensively to manage and control the electrical systems that support the engine and other vehicle functions. These resistors play a crucial role in ensuring that the vehicle's electrical systems operate efficiently, contributing to improved fuel efficiency and reduced emissions. For example, alloy shunts are used in battery management systems to monitor the state of charge and health of the battery, ensuring that it operates within safe parameters. Similarly, alloy film/foil resistors are used in engine control units to provide precise control over fuel injection and ignition timing, optimizing engine performance and reducing emissions. In NEVs, the role of alloy resistors becomes even more critical, as these vehicles rely heavily on electrical systems for propulsion and other functions. Alloy resistors are used in various applications, including power electronics, battery management systems, and electric motor control. In power electronics, pure alloy resistors are used to handle high power loads and ensure efficient energy conversion, which is essential for the performance and range of electric vehicles. In battery management systems, alloy shunts provide accurate current measurements, enabling precise control over charging and discharging processes. This is crucial for maintaining battery health and extending the lifespan of the vehicle's battery pack. Additionally, alloy film/foil resistors are used in electric motor control systems to provide precise control over motor speed and torque, ensuring smooth and efficient operation. As the automotive industry continues to shift towards electrification, the demand for advanced alloy resistors is expected to grow, driven by the need for more efficient and reliable electrical systems in both ICEVs and NEVs. Manufacturers are focusing on developing resistors that can meet the unique challenges of these vehicles, ensuring that they can operate effectively in a wide range of conditions and contribute to the overall performance and sustainability of the automotive industry.

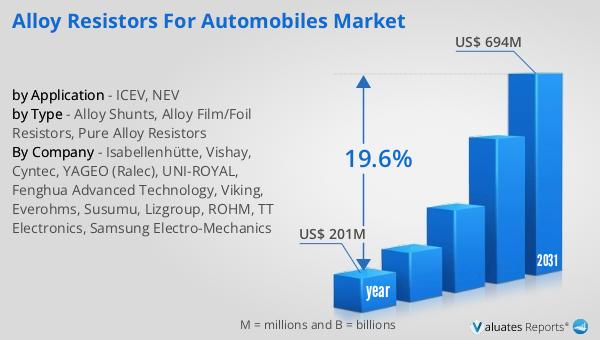

Global Alloy Resistors for Automobiles Market Outlook:

The global market for Alloy Resistors for Automobiles was valued at $201 million in 2024 and is anticipated to expand to a revised size of $694 million by 2031, reflecting a compound annual growth rate (CAGR) of 19.6% during the forecast period. This significant growth underscores the increasing demand for alloy resistors in the automotive sector, driven by advancements in vehicle technology and the shift towards electrification. During the same period, China's production and sales of New Energy Vehicles (NEVs) reached 9.587 million and 9.495 million units, respectively, marking year-on-year increases of 35.8% and 37.9%. This surge in NEV production and sales highlights the growing importance of alloy resistors in supporting the electrical systems of these vehicles. As the automotive industry continues to evolve, the demand for reliable and efficient electrical components like alloy resistors is expected to rise, driving further growth in this market. Manufacturers are investing in research and development to create resistors that meet the stringent requirements of modern vehicles, ensuring that they can operate effectively in a wide range of conditions. This focus on innovation and quality is essential for the continued growth and success of the Global Alloy Resistors for Automobiles Market.

| Report Metric | Details |

| Report Name | Alloy Resistors for Automobiles Market |

| Accounted market size in year | US$ 201 million |

| Forecasted market size in 2031 | US$ 694 million |

| CAGR | 19.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Isabellenhütte, Vishay, Cyntec, YAGEO (Ralec), UNI-ROYAL, Fenghua Advanced Technology, Viking, Everohms, Susumu, Lizgroup, ROHM, TT Electronics, Samsung Electro-Mechanics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |