What is Global Seamless Flux Cored Wire Market?

The Global Seamless Flux Cored Wire Market is a specialized segment within the welding industry that focuses on the production and distribution of seamless flux cored wires. These wires are essential in various welding applications due to their efficiency and effectiveness in creating strong, durable welds. Unlike traditional welding wires, seamless flux cored wires are designed with a continuous tubular structure filled with flux, which helps in stabilizing the arc and improving the overall quality of the weld. This market is driven by the increasing demand for high-performance welding solutions across various industries, including construction, automotive, and manufacturing. The seamless design of these wires eliminates the risk of moisture absorption, which can lead to defects in the weld, making them highly reliable and preferred in critical applications. As industries continue to seek advanced welding technologies to enhance productivity and quality, the Global Seamless Flux Cored Wire Market is expected to witness significant growth. The market's expansion is also fueled by technological advancements and the development of new materials that enhance the performance of these wires, catering to the evolving needs of end-users.

Gas Shielded Seamless Flux Cored Wire, Self-Shielded Seamless Flux Cored Wire in the Global Seamless Flux Cored Wire Market:

Gas Shielded Seamless Flux Cored Wire and Self-Shielded Seamless Flux Cored Wire are two primary types of wires within the Global Seamless Flux Cored Wire Market, each serving distinct purposes and applications. Gas Shielded Seamless Flux Cored Wire is designed to be used with an external shielding gas, typically a mixture of carbon dioxide and argon, which protects the weld pool from atmospheric contamination. This type of wire is known for producing high-quality welds with excellent mechanical properties, making it ideal for applications that require precision and strength, such as in the automotive and aerospace industries. The external gas shield helps in achieving a stable arc and reduces spatter, resulting in cleaner welds. On the other hand, Self-Shielded Seamless Flux Cored Wire does not require an external shielding gas, as the flux within the wire itself generates the necessary protection during the welding process. This makes it highly convenient for outdoor and field applications where carrying gas cylinders might be impractical. Self-shielded wires are particularly useful in construction and infrastructure projects, where ease of use and portability are crucial. They are also favored in situations where wind or other environmental factors might disrupt the shielding gas, ensuring consistent weld quality. Both types of wires offer unique advantages and are chosen based on the specific requirements of the welding task at hand. The seamless design of these wires further enhances their performance by preventing moisture absorption, which can lead to hydrogen-induced cracking and other weld defects. As industries continue to demand more efficient and reliable welding solutions, the development and adoption of these seamless flux cored wires are expected to grow, driven by their ability to deliver superior weld quality and adaptability to various working conditions.

Shipbuilding, Oil, Bridge Construction, Other in the Global Seamless Flux Cored Wire Market:

The Global Seamless Flux Cored Wire Market finds extensive usage across several key industries, including shipbuilding, oil, bridge construction, and others, due to its ability to deliver high-quality welds with enhanced efficiency and reliability. In the shipbuilding industry, seamless flux cored wires are crucial for constructing and repairing ships, where strong and durable welds are essential to withstand harsh marine environments. The seamless design of these wires ensures that the welds are free from defects such as porosity, which can compromise the structural integrity of the vessel. In the oil industry, seamless flux cored wires are used in the construction and maintenance of pipelines and other infrastructure, where they provide the necessary strength and corrosion resistance to handle the demanding conditions of oil extraction and transportation. The ability to produce consistent and high-quality welds is vital in preventing leaks and ensuring the safe operation of oil facilities. In bridge construction, seamless flux cored wires are employed to join steel components, providing the necessary strength and durability to support heavy loads and withstand environmental stresses. The use of these wires helps in achieving precise and reliable welds, which are critical for the safety and longevity of bridges. Additionally, seamless flux cored wires are used in various other industries, such as automotive and manufacturing, where they contribute to the production of high-performance components and structures. The versatility and reliability of seamless flux cored wires make them an indispensable tool in modern welding applications, driving their demand across diverse sectors. As industries continue to seek advanced welding solutions to enhance productivity and quality, the Global Seamless Flux Cored Wire Market is poised for significant growth, supported by ongoing technological advancements and the development of new materials that enhance the performance of these wires.

Global Seamless Flux Cored Wire Market Outlook:

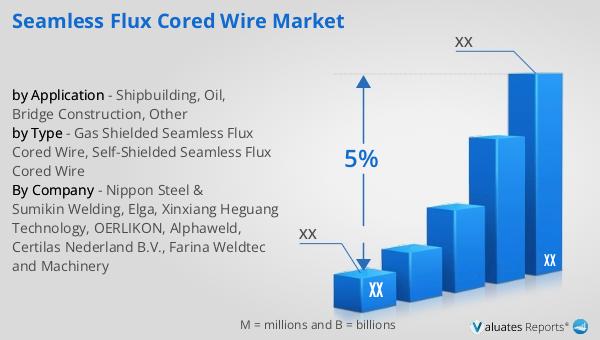

The outlook for the Global Seamless Flux Cored Wire Market can be compared to the trends observed in the pharmaceutical and chemical drug markets. In 2022, the global pharmaceutical market was valued at 1,475 billion USD, with an expected compound annual growth rate (CAGR) of 5% over the next six years. This growth reflects the increasing demand for healthcare solutions and innovations in drug development. Similarly, the chemical drug market has shown significant growth, rising from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This increase highlights the expanding need for chemical-based medications and treatments. While the Global Seamless Flux Cored Wire Market operates in a different industry, the growth patterns observed in these markets underscore the importance of innovation and technological advancement in driving market expansion. As industries continue to evolve and seek more efficient and reliable solutions, the demand for seamless flux cored wires is expected to rise, supported by the ongoing development of new materials and technologies that enhance their performance. The seamless design of these wires, which prevents moisture absorption and ensures high-quality welds, makes them a preferred choice in critical applications across various sectors. As a result, the Global Seamless Flux Cored Wire Market is well-positioned to capitalize on the growing demand for advanced welding solutions, driven by the need for improved productivity and quality in modern industrial applications.

| Report Metric | Details |

| Report Name | Seamless Flux Cored Wire Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nippon Steel & Sumikin Welding, Elga, Xinxiang Heguang Technology, OERLIKON, Alphaweld, Certilas Nederland B.V., Farina Weldtec and Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |