What is Global Resin Material PBT for Electric Vehicles Market?

Global Resin Material PBT for Electric Vehicles Market refers to the industry focused on the production and application of Polybutylene Terephthalate (PBT) resins specifically for electric vehicles (EVs). PBT is a type of thermoplastic polyester known for its excellent mechanical properties, thermal stability, and electrical insulation capabilities. These characteristics make it an ideal material for various components in electric vehicles, such as connectors, sensors, and housings for electronic control units. As the demand for electric vehicles continues to rise globally, driven by environmental concerns and regulatory mandates for reducing carbon emissions, the market for PBT resins is also expanding. Manufacturers are increasingly investing in research and development to enhance the properties of PBT, making it more suitable for the evolving needs of the EV industry. The global market for PBT resins is characterized by a competitive landscape with numerous players striving to innovate and capture market share. This market is poised for significant growth as electric vehicles become more prevalent, and the need for high-performance materials becomes more critical. The focus on sustainability and energy efficiency further propels the demand for PBT resins in the automotive sector.

Injection Molding, Extrusion Molding in the Global Resin Material PBT for Electric Vehicles Market:

Injection molding and extrusion molding are two prominent manufacturing processes used in the production of components made from Polybutylene Terephthalate (PBT) resin for electric vehicles. Injection molding is a process where PBT resin is melted and injected into a mold cavity under high pressure. This method is highly efficient for producing complex shapes with high precision and is widely used for manufacturing small to medium-sized components such as connectors, housings, and brackets in electric vehicles. The advantages of injection molding include its ability to produce parts with intricate details, consistent quality, and minimal waste. It is particularly beneficial for high-volume production runs, making it a cost-effective solution for the automotive industry. On the other hand, extrusion molding involves forcing melted PBT resin through a die to create continuous shapes, which are then cut to the desired length. This process is ideal for producing long, uniform components such as cables, tubes, and profiles used in electric vehicles. Extrusion molding offers benefits such as high production speed, versatility in shape and size, and the ability to produce parts with excellent surface finish. Both injection and extrusion molding processes play a crucial role in the global resin material PBT market for electric vehicles, as they enable the production of high-quality components that meet the stringent requirements of the automotive industry. The choice between these two methods depends on the specific application, design complexity, and production volume required. As the demand for electric vehicles continues to grow, manufacturers are increasingly adopting advanced molding technologies to enhance the performance and efficiency of PBT components. Innovations in molding techniques, such as the use of advanced simulation software and automation, are further driving the development of high-performance PBT parts for electric vehicles. These advancements not only improve the quality and reliability of the components but also contribute to reducing production costs and environmental impact. The integration of PBT resins in electric vehicles through injection and extrusion molding is a testament to the material's versatility and adaptability in meeting the evolving needs of the automotive industry.

HEV, PHEV in the Global Resin Material PBT for Electric Vehicles Market:

The usage of Global Resin Material PBT for Electric Vehicles Market in Hybrid Electric Vehicles (HEV) and Plug-in Hybrid Electric Vehicles (PHEV) is significant due to the material's unique properties. In HEVs, PBT resins are used extensively in the electrical and electronic components that are crucial for the vehicle's operation. These components include connectors, sensors, and housings for electronic control units, which require materials that can withstand high temperatures and provide excellent electrical insulation. PBT's thermal stability and mechanical strength make it an ideal choice for these applications, ensuring the reliability and safety of the vehicle's electrical systems. In PHEVs, the demand for PBT resins is even more pronounced due to the increased complexity of the vehicle's powertrain system. PHEVs combine an internal combustion engine with an electric motor and a larger battery pack, necessitating the use of materials that can handle higher electrical loads and provide superior insulation. PBT resins are used in the production of battery housings, cable insulation, and other critical components that require high-performance materials to ensure efficient energy management and safety. The use of PBT in these applications not only enhances the performance of the vehicle but also contributes to its overall energy efficiency and environmental sustainability. As the automotive industry continues to shift towards electrification, the demand for high-quality materials like PBT is expected to grow, driven by the need for reliable and efficient components in HEVs and PHEVs. Manufacturers are investing in research and development to further improve the properties of PBT resins, making them more suitable for the demanding requirements of hybrid and plug-in hybrid vehicles. This includes enhancing their thermal conductivity, flame retardancy, and resistance to chemicals and moisture. The integration of PBT resins in HEVs and PHEVs is a testament to the material's versatility and adaptability in meeting the evolving needs of the automotive industry. As the market for electric vehicles continues to expand, the role of PBT resins in ensuring the performance, safety, and sustainability of these vehicles will become increasingly important.

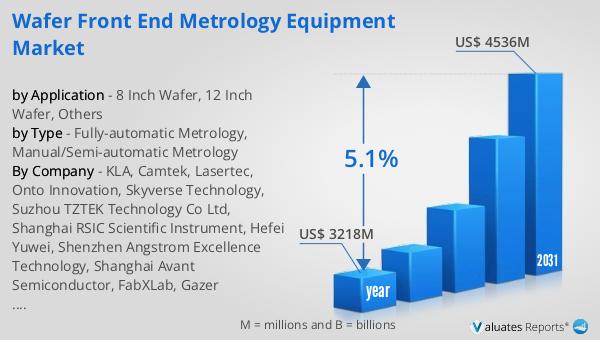

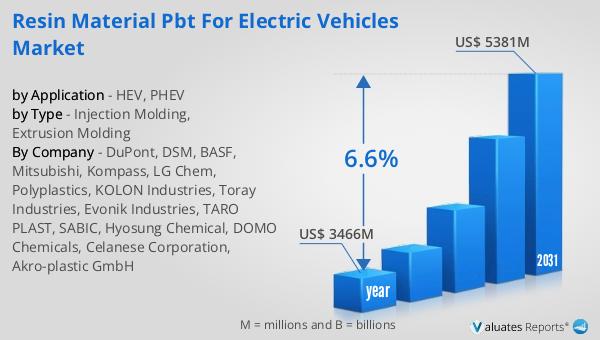

Global Resin Material PBT for Electric Vehicles Market Outlook:

The global market for Resin Material PBT for Electric Vehicles was valued at approximately $3,466 million in 2024, with projections indicating a growth to around $5,381 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.6% over the forecast period. The increasing adoption of electric vehicles, particularly in Europe, is a significant driver of this market expansion. In 2022, sales of pure electric vehicles in Europe surged by 29% year-on-year, reaching 1.58 million units. This trend underscores the growing demand for sustainable transportation solutions and the critical role of high-performance materials like PBT in supporting this transition. As electric vehicles become more prevalent, the need for reliable and efficient components made from PBT resins will continue to rise. Manufacturers are focusing on enhancing the properties of PBT to meet the stringent requirements of the automotive industry, ensuring that these materials can withstand the demanding conditions of electric vehicle applications. The market outlook for PBT resins in the electric vehicle sector is promising, driven by the increasing emphasis on sustainability, energy efficiency, and the reduction of carbon emissions. As the industry continues to evolve, the demand for high-quality materials like PBT will play a crucial role in shaping the future of electric mobility.

| Report Metric | Details |

| Report Name | Resin Material PBT for Electric Vehicles Market |

| Accounted market size in year | US$ 3466 million |

| Forecasted market size in 2031 | US$ 5381 million |

| CAGR | 6.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DuPont, DSM, BASF, Mitsubishi, Kompass, LG Chem, Polyplastics, KOLON Industries, Toray Industries, Evonik Industries, TARO PLAST, SABIC, Hyosung Chemical, DOMO Chemicals, Celanese Corporation, Akro-plastic GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |