What is Global Wafer Front End Metrology Equipment Market?

The Global Wafer Front End Metrology Equipment Market is a specialized segment within the semiconductor industry that focuses on the measurement and analysis of wafers during the initial stages of semiconductor manufacturing. These wafers are thin slices of semiconductor material, such as silicon, which serve as the foundation for integrated circuits and other microdevices. Metrology equipment is crucial in this context as it ensures the precision and accuracy of the wafers, which is vital for the performance and reliability of the final semiconductor products. This market encompasses a range of technologies and tools designed to measure various parameters of the wafers, such as thickness, flatness, and surface quality. The demand for such equipment is driven by the increasing complexity of semiconductor devices and the need for higher precision in manufacturing processes. As the semiconductor industry continues to evolve, the role of metrology equipment becomes even more critical, ensuring that the wafers meet the stringent quality standards required for advanced electronic devices. The market is characterized by continuous innovation and technological advancements, aimed at improving measurement accuracy and efficiency.

Fully-automatic Metrology, Manual/Semi-automatic Metrology in the Global Wafer Front End Metrology Equipment Market:

Fully-automatic metrology and manual/semi-automatic metrology are two distinct approaches within the Global Wafer Front End Metrology Equipment Market, each offering unique advantages and applications. Fully-automatic metrology systems are designed to operate with minimal human intervention, providing high throughput and consistency in measurements. These systems are equipped with advanced sensors and software algorithms that enable them to perform complex measurements quickly and accurately. They are particularly beneficial in high-volume manufacturing environments where speed and precision are paramount. The automation reduces the likelihood of human error, ensuring consistent quality across large batches of wafers. On the other hand, manual/semi-automatic metrology systems require some level of human involvement, either in setting up the equipment or in interpreting the results. These systems are often more flexible and can be adapted to a wider range of measurement tasks. They are ideal for research and development settings or for smaller production runs where customization and adaptability are more important than speed. While they may not match the throughput of fully-automatic systems, manual/semi-automatic systems offer greater control over the measurement process, allowing operators to make adjustments and optimizations as needed. Both types of metrology systems play a crucial role in the semiconductor manufacturing process, ensuring that wafers meet the necessary specifications for further processing. The choice between fully-automatic and manual/semi-automatic systems depends on various factors, including the scale of production, the complexity of the measurements required, and the specific needs of the manufacturing process. As technology continues to advance, the capabilities of both types of systems are expected to improve, offering even greater precision and efficiency in wafer metrology.

8 Inch Wafer, 12 Inch Wafer, Others in the Global Wafer Front End Metrology Equipment Market:

The Global Wafer Front End Metrology Equipment Market finds its application in various wafer sizes, including 8-inch wafers, 12-inch wafers, and others. Each wafer size presents unique challenges and requirements for metrology equipment. 8-inch wafers, also known as 200mm wafers, have been a standard in the semiconductor industry for many years. They are commonly used in the production of a wide range of electronic components, from microcontrollers to sensors. Metrology equipment for 8-inch wafers must be capable of handling the specific dimensions and characteristics of these wafers, ensuring that they meet the necessary quality standards. The equipment must be precise enough to detect any defects or irregularities that could affect the performance of the final products. 12-inch wafers, or 300mm wafers, represent a more recent advancement in semiconductor manufacturing. They offer several advantages over 8-inch wafers, including a larger surface area that allows for more chips to be produced from a single wafer. This increases the efficiency of the manufacturing process and reduces costs. However, the larger size of 12-inch wafers also presents new challenges for metrology equipment. The equipment must be able to accurately measure the larger surface area and detect any defects that could impact the performance of the chips. This requires advanced sensors and algorithms capable of handling the increased complexity of the measurements. In addition to 8-inch and 12-inch wafers, the Global Wafer Front End Metrology Equipment Market also serves other wafer sizes, including smaller and larger wafers used in specialized applications. These wafers may require customized metrology solutions to address their unique characteristics and requirements. The versatility of metrology equipment is crucial in this context, as it must be able to adapt to different wafer sizes and measurement tasks. As the semiconductor industry continues to evolve, the demand for metrology equipment that can handle a wide range of wafer sizes is expected to grow, driving further innovation and development in this market.

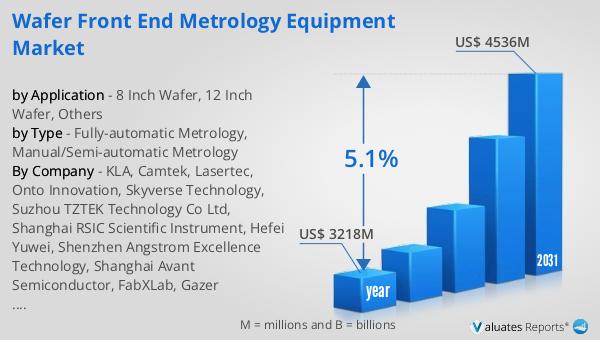

Global Wafer Front End Metrology Equipment Market Outlook:

The worldwide market for Wafer Front End Metrology Equipment was estimated to be worth $3,218 million in 2024. It is anticipated to expand to a revised valuation of $4,536 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.1% over the forecast period. This growth is indicative of the increasing demand for precision and accuracy in semiconductor manufacturing, driven by the rapid advancements in technology and the growing complexity of electronic devices. As the semiconductor industry continues to innovate, the need for advanced metrology equipment becomes more pronounced, ensuring that wafers meet the stringent quality standards required for modern electronic components. The market's expansion is also fueled by the rising adoption of automation in manufacturing processes, which enhances efficiency and reduces the likelihood of human error. As a result, manufacturers are increasingly investing in state-of-the-art metrology equipment to maintain a competitive edge in the industry. This trend is expected to continue, with further advancements in technology and increasing demand for high-quality semiconductor products driving the growth of the Global Wafer Front End Metrology Equipment Market.

| Report Metric | Details |

| Report Name | Wafer Front End Metrology Equipment Market |

| Accounted market size in year | US$ 3218 million |

| Forecasted market size in 2031 | US$ 4536 million |

| CAGR | 5.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KLA, Camtek, Lasertec, Onto Innovation, Skyverse Technology, Suzhou TZTEK Technology Co Ltd, Shanghai RSIC Scientific Instrument, Hefei Yuwei, Shenzhen Angstrom Excellence Technology, Shanghai Avant Semiconductor, FabXLab, Gazer Semiconductor, Shuz Tung Machinery Industrial, Muetec, Unity Semiconductor SAS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |