What is Global Polyethylene Damp Proof Membranes Market?

The Global Polyethylene Damp Proof Membranes Market refers to the worldwide industry focused on the production and distribution of polyethylene-based membranes designed to prevent moisture ingress in buildings. These membranes are crucial in construction as they act as barriers against dampness, which can cause structural damage and promote mold growth. Polyethylene, a versatile and durable plastic, is the primary material used due to its excellent resistance to moisture and chemicals. The market encompasses various types of membranes, differing in thickness and application, to cater to diverse construction needs. As urbanization and infrastructure development continue to rise globally, the demand for effective moisture control solutions like polyethylene damp proof membranes is expected to grow. This market is driven by the need for sustainable building practices and the increasing awareness of the long-term benefits of moisture protection in construction. Manufacturers are continually innovating to improve the performance and environmental impact of these membranes, making them more efficient and eco-friendly. The market's growth is also supported by stringent building regulations that mandate the use of damp proofing materials to ensure the longevity and safety of structures.

1200 Gauge/300μm, 2000 Gauge/500μm in the Global Polyethylene Damp Proof Membranes Market:

In the Global Polyethylene Damp Proof Membranes Market, two common specifications are the 1200 Gauge/300μm and 2000 Gauge/500μm membranes. These specifications refer to the thickness and density of the membranes, which determine their suitability for different applications. The 1200 Gauge/300μm membrane is a medium-duty option, often used in residential and light commercial construction. It provides adequate protection against moisture for most standard building projects, ensuring that homes and small commercial buildings remain dry and free from damp-related issues. This type of membrane is favored for its balance between cost-effectiveness and performance, making it a popular choice for builders and contractors working on budget-conscious projects. On the other hand, the 2000 Gauge/500μm membrane is a heavy-duty option, designed for more demanding applications where higher levels of moisture resistance are required. This thicker membrane is typically used in industrial settings or in areas with high water tables, where the risk of moisture ingress is significantly greater. Its robust construction provides superior protection, ensuring that even in challenging environments, buildings remain dry and structurally sound. The choice between these two specifications depends largely on the specific requirements of the construction project, including the expected exposure to moisture and the desired longevity of the building. In regions with stringent building codes, the use of thicker membranes like the 2000 Gauge/500μm may be mandated to ensure compliance with safety and durability standards. Additionally, the environmental conditions of the construction site play a crucial role in determining the appropriate membrane specification. For instance, in areas prone to heavy rainfall or flooding, the 2000 Gauge/500μm membrane would be the preferred choice due to its enhanced protective capabilities. Conversely, in drier climates or for projects with limited exposure to moisture, the 1200 Gauge/300μm membrane may suffice, offering a cost-effective solution without compromising on quality. The Global Polyethylene Damp Proof Membranes Market continues to evolve, with manufacturers exploring new materials and technologies to enhance the performance of these membranes. Innovations such as reinforced membranes and those with improved UV resistance are gaining traction, offering additional benefits to builders and property owners. As the market grows, the availability of a wide range of specifications ensures that there is a suitable damp proof membrane for every construction need, from small residential projects to large-scale industrial developments. This diversity in product offerings not only caters to the varying demands of the construction industry but also supports the global push towards more sustainable and resilient building practices.

Residential, Commercial Building, Industrial Building in the Global Polyethylene Damp Proof Membranes Market:

The usage of Global Polyethylene Damp Proof Membranes Market products spans across various sectors, including residential, commercial, and industrial buildings, each with its unique requirements and challenges. In residential construction, polyethylene damp proof membranes are primarily used to protect homes from moisture ingress, which can lead to structural damage and health issues due to mold growth. These membranes are typically installed beneath concrete floors and within walls to create a barrier that prevents dampness from penetrating the living spaces. Homeowners benefit from the enhanced durability and comfort of their homes, as well as the reduced risk of costly repairs associated with moisture damage. In commercial buildings, the need for effective moisture control is equally critical. Polyethylene damp proof membranes are used in the construction of offices, retail spaces, and other commercial properties to ensure a dry and stable environment. These membranes help maintain the integrity of the building materials, preventing issues such as warping, cracking, and deterioration that can arise from prolonged exposure to moisture. For businesses, this translates to lower maintenance costs and a more pleasant environment for employees and customers. In industrial buildings, the demands on damp proof membranes are even greater due to the often harsh and variable conditions. Industrial facilities, such as factories and warehouses, require robust moisture protection to safeguard equipment, inventory, and the structural integrity of the building itself. Polyethylene damp proof membranes used in these settings are typically of higher gauge and thickness, providing superior resistance to moisture and chemical exposure. This ensures that industrial operations can continue uninterrupted, with minimal risk of damage or downtime caused by moisture-related issues. Across all these sectors, the use of polyethylene damp proof membranes is driven by the need for long-lasting and reliable moisture protection solutions. As building codes and regulations become more stringent, the demand for high-quality damp proof membranes is expected to increase, further solidifying their role in modern construction practices. The versatility and effectiveness of polyethylene damp proof membranes make them an indispensable component in the construction industry, supporting the development of safe, durable, and sustainable buildings worldwide.

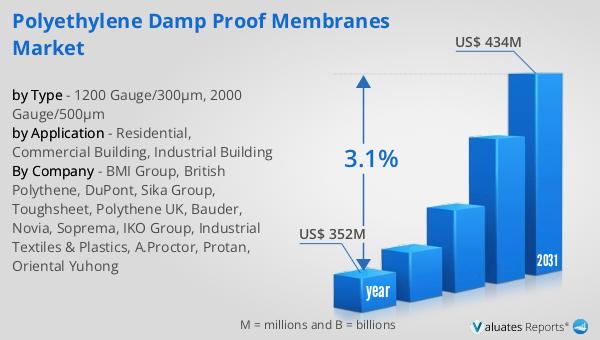

Global Polyethylene Damp Proof Membranes Market Outlook:

The global market for Polyethylene Damp Proof Membranes was valued at $352 million in 2024, and it is anticipated to grow to a revised size of $434 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.1% over the forecast period. This steady increase in market size reflects the rising demand for effective moisture control solutions in the construction industry. As urbanization continues to expand and infrastructure projects multiply, the need for reliable damp proofing materials becomes more pronounced. Polyethylene damp proof membranes are favored for their durability, cost-effectiveness, and ease of installation, making them a preferred choice among builders and contractors. The market's growth is also supported by increasing awareness of the long-term benefits of moisture protection, including enhanced building longevity and reduced maintenance costs. Additionally, as environmental concerns gain prominence, manufacturers are focusing on developing more sustainable and eco-friendly membrane options, further driving market expansion. The projected growth in the global market for Polyethylene Damp Proof Membranes underscores the importance of these products in modern construction practices, highlighting their role in ensuring the safety, durability, and sustainability of buildings worldwide.

| Report Metric | Details |

| Report Name | Polyethylene Damp Proof Membranes Market |

| Accounted market size in year | US$ 352 million |

| Forecasted market size in 2031 | US$ 434 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | BMI Group, British Polythene, DuPont, Sika Group, Toughsheet, Polythene UK, Bauder, Novia, Soprema, IKO Group, Industrial Textiles & Plastics, A.Proctor, Protan, Oriental Yuhong |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |