What is Global Foam Structural Core Materials Market?

The Global Foam Structural Core Materials Market is a specialized segment within the broader materials industry, focusing on the production and application of foam-based core materials used in various structural applications. These materials are integral to the construction of lightweight, high-strength composite structures. Foam structural core materials are typically used in sandwich panels, which consist of two thin, strong outer layers and a lightweight core. This configuration provides excellent strength-to-weight ratios, making them ideal for industries that require durable yet lightweight materials. The market encompasses a range of foam types, including PVC, PET, PES, and PMI, each offering unique properties that cater to specific industry needs. The demand for these materials is driven by their application in sectors such as aerospace, automotive, wind energy, and construction, where reducing weight while maintaining structural integrity is crucial. As industries continue to seek innovative solutions to improve efficiency and performance, the Global Foam Structural Core Materials Market is expected to grow, driven by advancements in material science and increasing adoption across various sectors. The market's growth is also supported by the rising emphasis on sustainability and energy efficiency, as these materials contribute to reducing the overall carbon footprint of the products they are used in.

PVC, PET, PES, PMI, Others in the Global Foam Structural Core Materials Market:

In the Global Foam Structural Core Materials Market, several types of foam materials are prominently used, each with distinct characteristics and applications. PVC (Polyvinyl Chloride) foam is one of the most widely used core materials due to its excellent mechanical properties, including high strength and stiffness, as well as its resistance to moisture and chemicals. PVC foam is often used in marine applications, wind turbine blades, and transportation due to its durability and lightweight nature. PET (Polyethylene Terephthalate) foam is another popular choice, known for its recyclability and good mechanical properties. It is increasingly used in applications where environmental considerations are important, such as in the automotive and construction industries. PET foam offers a good balance between performance and cost, making it an attractive option for many manufacturers. PES (Polyethersulfone) foam is known for its high-temperature resistance and excellent fire retardant properties, making it suitable for aerospace and transportation applications where safety is a critical concern. PMI (Polymethacrylimide) foam is characterized by its high strength-to-weight ratio and excellent thermal insulation properties. It is often used in high-performance applications such as aerospace and sporting goods, where minimizing weight without compromising strength is essential. Other foam materials in the market include SAN (Styrene Acrylonitrile) and PU (Polyurethane), each offering unique benefits that cater to specific industry needs. SAN foam is known for its good chemical resistance and thermal stability, while PU foam is valued for its versatility and cost-effectiveness. The choice of foam material depends on various factors, including the specific requirements of the application, cost considerations, and environmental impact. As industries continue to evolve and demand more efficient and sustainable solutions, the development and adoption of advanced foam structural core materials are expected to grow, driven by ongoing research and innovation in material science.

Wind Energy Industry, Transportation Industry, Construction, Others in the Global Foam Structural Core Materials Market:

The Global Foam Structural Core Materials Market finds extensive usage across various industries, each leveraging the unique properties of these materials to enhance performance and efficiency. In the wind energy industry, foam structural core materials are crucial in the construction of wind turbine blades. These materials provide the necessary strength and stiffness while keeping the blades lightweight, which is essential for efficient energy generation. The use of foam cores helps in reducing the overall weight of the blades, allowing for longer and more efficient designs that can capture more wind energy. In the transportation industry, foam structural core materials are used to manufacture lightweight components that contribute to fuel efficiency and reduced emissions. These materials are used in the construction of vehicle bodies, interior panels, and other components where reducing weight without compromising safety and performance is critical. The construction industry also benefits from foam structural core materials, particularly in the development of energy-efficient buildings. These materials are used in sandwich panels for walls, roofs, and floors, providing excellent insulation properties that help in reducing energy consumption for heating and cooling. Additionally, foam core materials are used in the construction of bridges and other infrastructure projects where lightweight and durable materials are required. Other industries, such as aerospace and marine, also utilize foam structural core materials to enhance performance and reduce weight. In aerospace, these materials are used in the construction of aircraft components, where reducing weight is crucial for fuel efficiency and performance. In the marine industry, foam core materials are used in the construction of boats and ships, providing buoyancy and structural integrity while keeping the vessels lightweight. As industries continue to prioritize sustainability and efficiency, the demand for foam structural core materials is expected to grow, driven by their ability to meet the evolving needs of various applications.

Global Foam Structural Core Materials Market Outlook:

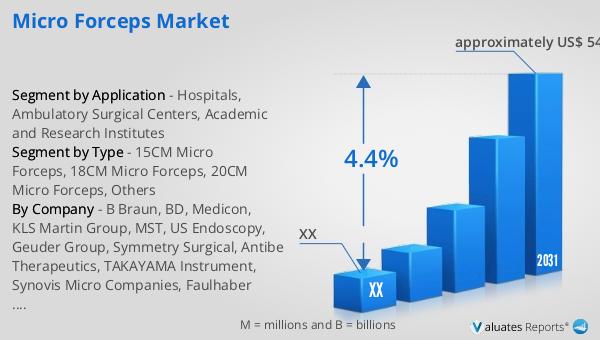

The global market for Foam Structural Core Materials was valued at approximately $722 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $958 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.2% over the forecast period. The steady increase in market size reflects the rising demand for lightweight and high-strength materials across various industries. As sectors such as wind energy, transportation, and construction continue to seek innovative solutions to improve efficiency and performance, the adoption of foam structural core materials is expected to rise. These materials offer a unique combination of properties, including high strength-to-weight ratios, excellent thermal insulation, and resistance to moisture and chemicals, making them ideal for a wide range of applications. The market's growth is also supported by advancements in material science and the increasing emphasis on sustainability and energy efficiency. As industries strive to reduce their carbon footprint and enhance product performance, the demand for foam structural core materials is likely to continue its upward trend. This positive market outlook underscores the importance of these materials in addressing the evolving needs of various sectors and highlights the potential for further innovation and development in this field.

| Report Metric | Details |

| Report Name | Foam Structural Core Materials Market |

| Accounted market size in year | US$ 722 million |

| Forecasted market size in 2031 | US$ 958 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | 3A Composites International AG (Schweiter Technologies AG), Diab Group AB, Gurit Holding AG, Armacell International S.A., Evonik Industries AG, Maricell S.R.L., Changzhou Tiansheng New Materials Co., Ltd., Corelite, Inc., Shanghai Yueke Compound Materials Co.,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |