What is Global Pharmaceutical Aseptic Transfer System Market?

The Global Pharmaceutical Aseptic Transfer System Market is a crucial segment within the pharmaceutical industry, focusing on the safe and sterile transfer of materials. This market is essential for maintaining the integrity and quality of pharmaceutical products during manufacturing and packaging processes. Aseptic transfer systems are designed to prevent contamination by ensuring that materials such as liquids, solids, and gases are transferred in a controlled environment. These systems are vital in the production of sterile drugs, vaccines, and other pharmaceutical products, where even the slightest contamination can lead to significant health risks. The market encompasses a variety of technologies and equipment, including isolators, transfer ports, and sterile connectors, all aimed at ensuring the highest levels of sterility. As the demand for sterile pharmaceutical products continues to rise, the Global Pharmaceutical Aseptic Transfer System Market is expected to grow, driven by advancements in technology and increasing regulatory requirements for product safety and quality. This market plays a pivotal role in supporting the pharmaceutical industry's efforts to deliver safe and effective medications to patients worldwide.

Solids Transfer System, Liquid Transfer System in the Global Pharmaceutical Aseptic Transfer System Market:

The Global Pharmaceutical Aseptic Transfer System Market includes various systems designed to handle the transfer of different types of materials, primarily focusing on solids and liquids. The Solids Transfer System is engineered to manage the movement of solid materials, such as powders and granules, in a sterile environment. This system is crucial in the pharmaceutical industry, where the handling of active pharmaceutical ingredients (APIs) and excipients must be conducted without contamination. Solids transfer systems often utilize technologies like split butterfly valves, which allow for the safe and sterile transfer of powders between containers. These systems are designed to minimize the risk of cross-contamination and ensure that the integrity of the materials is maintained throughout the transfer process. On the other hand, the Liquid Transfer System is tailored for the movement of liquid substances, which are prevalent in the production of injectable drugs, vaccines, and other liquid formulations. Liquid transfer systems employ technologies such as sterile connectors and tubing systems to facilitate the safe transfer of liquids in a controlled environment. These systems are designed to prevent microbial contamination and ensure that the liquid products remain sterile from production to packaging. Both solids and liquid transfer systems are integral components of the Global Pharmaceutical Aseptic Transfer System Market, addressing the unique challenges associated with handling different types of materials. The demand for these systems is driven by the increasing need for sterile pharmaceutical products and the stringent regulatory requirements governing their production. As the pharmaceutical industry continues to evolve, the development of advanced aseptic transfer systems will be essential in ensuring the safe and efficient production of high-quality pharmaceutical products.

Pharmaceutical Companies, Contract Development and Manufacturing Organizations, Others in the Global Pharmaceutical Aseptic Transfer System Market:

The Global Pharmaceutical Aseptic Transfer System Market finds extensive usage across various sectors within the pharmaceutical industry, including pharmaceutical companies, Contract Development and Manufacturing Organizations (CDMOs), and other related entities. Pharmaceutical companies are the primary users of aseptic transfer systems, as they are responsible for the production of a wide range of sterile products, including drugs, vaccines, and biologics. These companies rely on aseptic transfer systems to maintain the sterility of their products throughout the manufacturing process, ensuring that they meet the stringent quality standards set by regulatory authorities. The use of aseptic transfer systems helps pharmaceutical companies minimize the risk of contamination, improve product quality, and enhance operational efficiency. Contract Development and Manufacturing Organizations (CDMOs) also play a significant role in the Global Pharmaceutical Aseptic Transfer System Market. These organizations provide outsourced services to pharmaceutical companies, including drug development, manufacturing, and packaging. CDMOs utilize aseptic transfer systems to ensure that the products they manufacture on behalf of their clients meet the required sterility standards. By employing advanced aseptic transfer technologies, CDMOs can offer high-quality manufacturing services, enabling pharmaceutical companies to focus on their core competencies. Other entities within the pharmaceutical industry, such as research institutions and regulatory bodies, also benefit from the use of aseptic transfer systems. Research institutions use these systems to conduct experiments and develop new pharmaceutical products in a controlled environment, while regulatory bodies rely on them to ensure compliance with safety and quality standards. Overall, the Global Pharmaceutical Aseptic Transfer System Market plays a vital role in supporting the pharmaceutical industry's efforts to deliver safe and effective medications to patients worldwide.

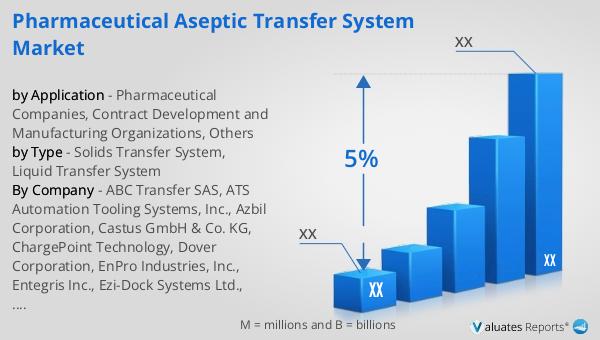

Global Pharmaceutical Aseptic Transfer System Market Outlook:

In 2022, the global pharmaceutical market reached a valuation of 1,475 billion USD, demonstrating a steady growth trajectory with a compound annual growth rate (CAGR) of 5% projected over the next six years. This growth reflects the increasing demand for pharmaceutical products and the continuous advancements in medical research and technology. In comparison, the chemical drug market has also shown significant growth, expanding from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This increase highlights the ongoing importance of chemical drugs within the broader pharmaceutical landscape, despite the rising interest in biologics and other advanced therapies. The growth in both the global pharmaceutical market and the chemical drug market underscores the critical role of innovation and regulatory compliance in driving industry expansion. As pharmaceutical companies continue to invest in research and development, the market is poised to deliver new and improved treatments that address a wide range of medical needs. The Global Pharmaceutical Aseptic Transfer System Market is expected to benefit from this growth, as the demand for sterile manufacturing processes and high-quality products continues to rise.

| Report Metric | Details |

| Report Name | Pharmaceutical Aseptic Transfer System Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABC Transfer SAS, ATS Automation Tooling Systems, Inc., Azbil Corporation, Castus GmbH & Co. KG, ChargePoint Technology, Dover Corporation, EnPro Industries, Inc., Entegris Inc., Ezi-Dock Systems Ltd., Getinge AB, ILC Dover LP, JCE Biotechnology, Rommelag, Sartorius AG, Single Use Support GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |