What is Global Oxidized High Density Polyethylene Waxes Market?

The Global Oxidized High Density Polyethylene (HDPE) Waxes Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of oxidized HDPE waxes. These waxes are derived from high-density polyethylene, a type of thermoplastic polymer known for its strength and durability. Through a process of oxidation, these waxes acquire unique properties that make them highly valuable across various industrial applications. The market for these waxes is driven by their versatility and effectiveness in enhancing the performance of products in which they are used. They are particularly noted for their role as lubricants, dispersing agents, and modifiers, which improve the processing and end-use characteristics of materials. The demand for oxidized HDPE waxes is influenced by their application in industries such as plastics, paints, inks, textiles, and paper, where they contribute to improved product quality and manufacturing efficiency. As industries continue to seek materials that offer both performance and sustainability, the market for oxidized HDPE waxes is expected to grow, driven by innovations and the development of new applications. This growth is supported by ongoing research and development efforts aimed at enhancing the properties and applications of these waxes.

Dry Oxidized, Wet Oxidized in the Global Oxidized High Density Polyethylene Waxes Market:

In the Global Oxidized High Density Polyethylene Waxes Market, two primary types of oxidized waxes are prevalent: Dry Oxidized and Wet Oxidized. Each type is distinguished by its production process and resultant properties, which cater to different industrial needs. Dry Oxidized HDPE waxes are produced through a process where polyethylene is exposed to oxygen in a dry environment, typically at elevated temperatures. This method results in waxes that possess a high degree of oxidation, leading to enhanced hardness and melting points. These characteristics make dry oxidized waxes particularly suitable for applications requiring high thermal stability and resistance to wear, such as in the production of high-performance coatings and adhesives. On the other hand, Wet Oxidized HDPE waxes are created by introducing polyethylene to an oxidizing agent in a liquid medium. This process allows for more controlled oxidation, resulting in waxes with a balanced set of properties, including improved flexibility and compatibility with other materials. Wet oxidized waxes are often preferred in applications where a softer, more pliable wax is needed, such as in the formulation of polishes and emulsions. The choice between dry and wet oxidized waxes depends largely on the specific requirements of the application, including factors such as temperature resistance, hardness, and compatibility with other components. Both types of waxes play a crucial role in enhancing the performance and durability of products across various industries. In the plastics industry, for example, oxidized HDPE waxes are used as lubricants and dispersing agents, facilitating the processing of polymers and improving the surface quality of finished products. In the coatings industry, these waxes contribute to the development of paints and inks with superior gloss, adhesion, and resistance to environmental factors. The paper industry benefits from the use of oxidized HDPE waxes in the production of coatings that enhance the printability and durability of paper products. In textiles, these waxes are used to improve the texture and finish of fabrics, providing a soft hand feel and resistance to abrasion. Other applications include their use in the formulation of polishes, where they provide a protective layer and enhance the shine of surfaces. The versatility of oxidized HDPE waxes, combined with their ability to improve the performance and sustainability of products, makes them an essential component in a wide range of industrial applications. As industries continue to evolve and seek materials that offer both performance and environmental benefits, the demand for oxidized HDPE waxes is expected to grow, driven by ongoing innovations and the development of new applications.

PVC Lubricant, Paint & Ink, Paper Industry, Textile, Others in the Global Oxidized High Density Polyethylene Waxes Market:

The Global Oxidized High Density Polyethylene Waxes Market finds extensive usage across several key areas, including PVC lubricants, paints and inks, the paper industry, textiles, and other applications. In the realm of PVC lubricants, oxidized HDPE waxes play a critical role in enhancing the processing and performance of polyvinyl chloride (PVC) products. These waxes act as internal and external lubricants, reducing friction during the extrusion and molding processes, which in turn improves the flow and surface finish of PVC products. This results in higher quality end-products with improved mechanical properties and surface aesthetics. In the paint and ink industry, oxidized HDPE waxes are valued for their ability to improve the gloss, adhesion, and durability of coatings. They act as dispersing agents, ensuring uniform distribution of pigments and other additives, which enhances the overall appearance and performance of paints and inks. Additionally, these waxes provide resistance to environmental factors such as moisture and UV radiation, extending the lifespan of coatings. In the paper industry, oxidized HDPE waxes are used to produce coatings that enhance the printability and durability of paper products. They improve the surface smoothness and gloss of paper, making it more suitable for high-quality printing applications. Furthermore, these waxes provide water resistance, which is essential for paper products used in humid or wet environments. In the textile industry, oxidized HDPE waxes are used to improve the texture and finish of fabrics. They provide a soft hand feel and enhance the resistance of textiles to abrasion and wear. This is particularly important in the production of garments and other textile products that require a high level of durability and comfort. Other applications of oxidized HDPE waxes include their use in the formulation of polishes, where they provide a protective layer and enhance the shine of surfaces. They are also used in the production of adhesives and sealants, where they improve the bonding strength and flexibility of these products. The versatility and effectiveness of oxidized HDPE waxes in these applications make them an essential component in a wide range of industrial processes. As industries continue to seek materials that offer both performance and sustainability, the demand for oxidized HDPE waxes is expected to grow, driven by ongoing innovations and the development of new applications.

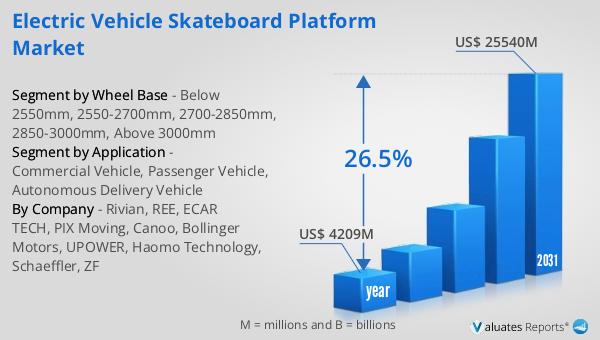

Global Oxidized High Density Polyethylene Waxes Market Outlook:

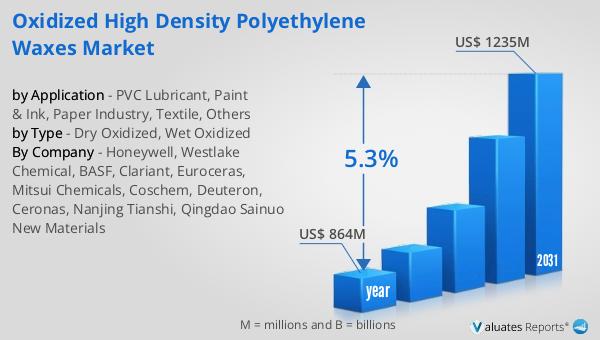

The global market for Oxidized High Density Polyethylene Waxes was valued at $864 million in 2024 and is anticipated to expand to a revised size of $1,235 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.3% during the forecast period. This growth trajectory underscores the increasing demand for these specialized waxes across various industries. The market's expansion is driven by the unique properties of oxidized HDPE waxes, which enhance the performance and durability of products in which they are used. Industries such as plastics, paints, inks, textiles, and paper are increasingly incorporating these waxes into their processes to improve product quality and manufacturing efficiency. The projected growth also highlights the ongoing innovations and development of new applications for oxidized HDPE waxes, as industries seek materials that offer both performance and sustainability. As the market continues to evolve, the demand for these waxes is expected to rise, driven by their versatility and effectiveness in enhancing the performance of a wide range of products. The anticipated growth in the market size reflects the increasing recognition of the value that oxidized HDPE waxes bring to various industrial applications, as well as the ongoing efforts to develop new and improved formulations that meet the evolving needs of industries worldwide.

| Report Metric | Details |

| Report Name | Oxidized High Density Polyethylene Waxes Market |

| Accounted market size in year | US$ 864 million |

| Forecasted market size in 2031 | US$ 1235 million |

| CAGR | 5.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Honeywell, Westlake Chemical, BASF, Clariant, Euroceras, Mitsui Chemicals, Coschem, Deuteron, Ceronas, Nanjing Tianshi, Qingdao Sainuo New Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |