What is Global Molecular Sieve for Oxygen Generator Market?

The Global Molecular Sieve for Oxygen Generator Market is a specialized segment within the broader industrial and medical gas industry. Molecular sieves are materials with tiny, uniform pores that can separate molecules based on size and shape. In the context of oxygen generators, these sieves are crucial for separating oxygen from other gases in the air, such as nitrogen. This separation process is vital for producing high-purity oxygen, which is essential for various applications. The market for molecular sieves in oxygen generators is driven by the increasing demand for oxygen in medical and industrial sectors. Medical facilities require a steady supply of oxygen for patient care, while industries use oxygen for processes like metal cutting and chemical production. The market is characterized by technological advancements aimed at improving the efficiency and capacity of molecular sieves, making them more effective in oxygen generation. Additionally, environmental regulations and the need for sustainable solutions are pushing manufacturers to innovate and develop eco-friendly products. As a result, the Global Molecular Sieve for Oxygen Generator Market is poised for growth, driven by the rising need for reliable and efficient oxygen generation solutions across various sectors.

3A, 4A, 5A, 13X in the Global Molecular Sieve for Oxygen Generator Market:

In the Global Molecular Sieve for Oxygen Generator Market, different types of molecular sieves, such as 3A, 4A, 5A, and 13X, play a crucial role in the efficient separation of gases. Each type of sieve has unique properties that make it suitable for specific applications. The 3A molecular sieve, with its pore size of approximately 3 angstroms, is primarily used for drying gases and liquids. It is particularly effective in removing moisture from air and other gases, which is essential in preventing corrosion and ensuring the longevity of oxygen generators. The 4A molecular sieve, with a slightly larger pore size of 4 angstroms, is versatile and can adsorb a variety of molecules, including water, carbon dioxide, and ammonia. This makes it ideal for applications where multiple impurities need to be removed from the air before oxygen generation. The 5A molecular sieve, with a pore size of 5 angstroms, is known for its ability to adsorb larger molecules, such as hydrocarbons and sulfur compounds. This makes it suitable for industrial applications where the purity of oxygen is critical. Lastly, the 13X molecular sieve, with its large pore size of 10 angstroms, is highly effective in separating nitrogen from oxygen, making it a popular choice for oxygen concentrators. Its high adsorption capacity and efficiency in nitrogen removal make it indispensable in both medical and industrial oxygen generation. The choice of molecular sieve depends on the specific requirements of the oxygen generation process, including the desired purity level and the types of impurities present in the air. Manufacturers in the Global Molecular Sieve for Oxygen Generator Market are continually researching and developing new formulations to enhance the performance and efficiency of these sieves. This includes improving their adsorption capacity, thermal stability, and resistance to chemical degradation. As a result, the market is witnessing a trend towards more advanced and specialized molecular sieves that can meet the growing demands of various industries. The development of these innovative products is crucial for ensuring the reliability and efficiency of oxygen generators, which are essential for both medical and industrial applications.

Medical Oxygen Generator, Industrial Oxygen Generator in the Global Molecular Sieve for Oxygen Generator Market:

The Global Molecular Sieve for Oxygen Generator Market finds significant usage in both medical and industrial applications, particularly in the production of oxygen. In the medical field, oxygen generators equipped with molecular sieves are vital for providing a continuous supply of oxygen to patients with respiratory conditions. These generators are used in hospitals, clinics, and home healthcare settings to ensure that patients receive the necessary oxygen therapy. The molecular sieves in these generators play a crucial role in separating oxygen from other gases in the air, ensuring that the oxygen delivered to patients is of high purity. This is essential for patient safety and effective treatment outcomes. In industrial settings, oxygen generators are used in various processes, such as metal cutting, welding, and chemical production. The molecular sieves in these generators help produce high-purity oxygen, which is necessary for achieving optimal results in these processes. For instance, in metal cutting and welding, high-purity oxygen ensures clean cuts and strong welds, while in chemical production, it enhances reaction efficiency and product quality. The use of molecular sieves in oxygen generators also contributes to cost savings and environmental sustainability. By enabling on-site oxygen production, these generators reduce the need for transporting and storing large volumes of oxygen, which can be costly and environmentally taxing. Additionally, the efficiency of molecular sieves in separating gases minimizes energy consumption, further reducing the environmental impact of oxygen production. As a result, the Global Molecular Sieve for Oxygen Generator Market is essential for meeting the growing demand for oxygen in both medical and industrial sectors, while also supporting sustainability efforts.

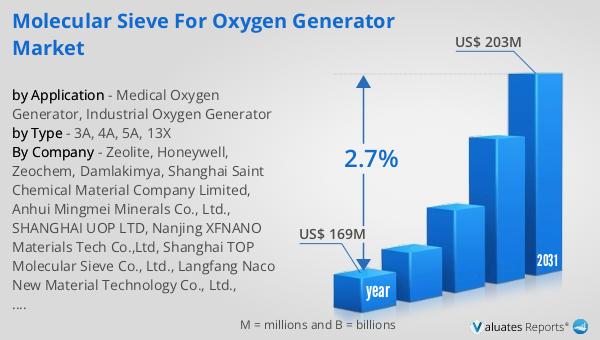

Global Molecular Sieve for Oxygen Generator Market Outlook:

The worldwide market for Molecular Sieve for Oxygen Generator was valued at $169 million in 2024 and is anticipated to expand to a revised size of $203 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.7% over the forecast period. This growth trajectory underscores the increasing demand for efficient and reliable oxygen generation solutions across various sectors. The market's expansion is driven by several factors, including the rising need for high-purity oxygen in medical and industrial applications, technological advancements in molecular sieve technology, and the growing emphasis on sustainable and eco-friendly solutions. As healthcare facilities and industries continue to seek efficient ways to produce oxygen on-site, the demand for advanced molecular sieves is expected to rise. These sieves are crucial for ensuring the purity and efficiency of oxygen generation, making them indispensable in both medical and industrial settings. Furthermore, the market's growth is supported by ongoing research and development efforts aimed at enhancing the performance and durability of molecular sieves. Manufacturers are investing in innovative technologies to improve the adsorption capacity, thermal stability, and chemical resistance of these sieves, ensuring they meet the evolving needs of various applications. As a result, the Global Molecular Sieve for Oxygen Generator Market is poised for steady growth, driven by the increasing demand for high-quality oxygen generation solutions and the continuous advancements in molecular sieve technology.

| Report Metric | Details |

| Report Name | Molecular Sieve for Oxygen Generator Market |

| Accounted market size in year | US$ 169 million |

| Forecasted market size in 2031 | US$ 203 million |

| CAGR | 2.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Zeolite, Honeywell, Zeochem, Damlakimya, Shanghai Saint Chemical Material Company Limited, Anhui Mingmei Minerals Co., Ltd., SHANGHAI UOP LTD, Nanjing XFNANO Materials Tech Co.,Ltd, Shanghai TOP Molecular Sieve Co., Ltd., Langfang Naco New Material Technology Co., Ltd., Luoyang Jalon Micro-nano New Materials Co.,ltd., Naike Chemical Equipment Packing Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |