What is Global Mold Release Sealer Market?

The Global Mold Release Sealer Market is a specialized segment within the broader industrial and manufacturing sectors, focusing on products that facilitate the easy removal of molded parts from molds. Mold release sealers are essential in various manufacturing processes, as they prevent the sticking of materials to molds, thereby ensuring smooth and efficient production. These sealers are used in industries such as automotive, aerospace, construction, and consumer goods, where precision and quality are paramount. The market for mold release sealers is driven by the increasing demand for high-quality finished products and the need for efficient manufacturing processes. As industries continue to evolve and innovate, the demand for advanced mold release solutions is expected to grow. The market is characterized by a diverse range of products, including water-based, solvent-based, and other specialized formulations, each catering to specific industrial needs. The global reach of this market highlights its importance in the manufacturing sector, with key players continuously developing new technologies to meet the ever-changing demands of the industry.

Water-Based, Solvent-Based, Others in the Global Mold Release Sealer Market:

In the Global Mold Release Sealer Market, products are primarily categorized into water-based, solvent-based, and other types, each offering unique benefits and applications. Water-based mold release sealers are increasingly popular due to their environmentally friendly nature. They are formulated with water as the primary solvent, reducing the emission of volatile organic compounds (VOCs) and making them safer for both the environment and workers. These sealers are ideal for applications where environmental regulations are stringent, and they provide excellent release properties without compromising on performance. Water-based sealers are particularly favored in industries such as automotive and consumer goods, where sustainability is a key concern. On the other hand, solvent-based mold release sealers are known for their superior performance in challenging conditions. They are formulated with organic solvents, which provide excellent release properties and durability. These sealers are often used in industries where high temperatures and pressures are involved, such as aerospace and heavy machinery manufacturing. Despite their effectiveness, solvent-based sealers are subject to stricter environmental regulations due to their higher VOC content. Manufacturers are continuously working to develop low-VOC solvent-based formulations to meet these regulatory requirements while maintaining performance standards. In addition to water-based and solvent-based sealers, the market also includes other specialized formulations designed for specific applications. These may include silicone-based sealers, which offer excellent heat resistance and are used in high-temperature applications, or fluoropolymer-based sealers, which provide exceptional chemical resistance and are used in industries dealing with aggressive chemicals. The choice of mold release sealer depends on various factors, including the type of material being molded, the operating conditions, and the specific requirements of the manufacturing process. As industries continue to innovate and demand more efficient and sustainable solutions, the development of new and improved mold release sealers remains a key focus for manufacturers. The diversity of products within the Global Mold Release Sealer Market ensures that there is a suitable solution for virtually every application, making it a vital component of modern manufacturing processes.

Metal, Plastic, Epoxy Resin, Ceramics, Other in the Global Mold Release Sealer Market:

The Global Mold Release Sealer Market finds extensive usage across various materials, including metal, plastic, epoxy resin, ceramics, and others, each with its unique requirements and challenges. In the metal industry, mold release sealers are crucial for processes such as die-casting and metal injection molding. These sealers prevent the adhesion of molten metal to the mold surfaces, ensuring smooth release and high-quality finished products. The use of mold release sealers in metal applications helps reduce defects, improve surface finish, and extend the life of molds, making them an essential component in the production of automotive parts, machinery components, and other metal products. In the plastic industry, mold release sealers are used in processes such as injection molding, blow molding, and thermoforming. They facilitate the easy removal of plastic parts from molds, reducing cycle times and improving production efficiency. Mold release sealers also help prevent defects such as warping, surface imperfections, and sticking, ensuring consistent quality in plastic products. The use of mold release sealers in plastic manufacturing is critical for producing a wide range of consumer goods, packaging materials, and industrial components. Epoxy resin applications also benefit from the use of mold release sealers. In industries such as electronics, aerospace, and construction, epoxy resins are used for their excellent adhesive properties and durability. Mold release sealers ensure that epoxy resin components can be easily removed from molds without damaging the intricate details or compromising the structural integrity of the parts. This is particularly important in the production of composite materials, where precision and quality are paramount. In the ceramics industry, mold release sealers play a vital role in processes such as slip casting and pressing. These sealers prevent the adhesion of ceramic materials to molds, allowing for the easy removal of greenware and reducing the risk of defects during firing. The use of mold release sealers in ceramics manufacturing helps improve product quality, reduce waste, and enhance production efficiency. Other materials, such as rubber and composites, also benefit from the use of mold release sealers. In the rubber industry, these sealers are used in processes such as tire manufacturing and rubber molding, where they help prevent sticking and ensure smooth release. In composite manufacturing, mold release sealers are essential for producing high-performance components used in industries such as aerospace, automotive, and sports equipment. The versatility and effectiveness of mold release sealers make them indispensable in a wide range of manufacturing processes, contributing to improved product quality, efficiency, and sustainability.

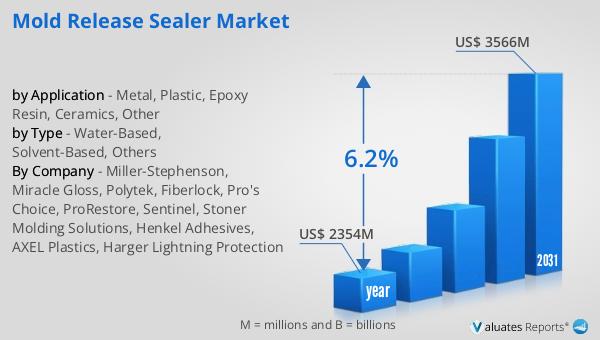

Global Mold Release Sealer Market Outlook:

The outlook for the Global Mold Release Sealer Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 2,354 million, reflecting its significant role in various industrial applications. Looking ahead, the market is expected to expand, reaching an estimated size of US$ 3,566 million by 2031. This growth is projected to occur at a compound annual growth rate (CAGR) of 6.2% over the forecast period. The increasing demand for high-quality finished products and efficient manufacturing processes is driving this growth. As industries continue to innovate and seek more sustainable and efficient solutions, the demand for advanced mold release sealers is expected to rise. The market's expansion is also supported by the continuous development of new technologies and formulations by key players in the industry. These advancements aim to meet the evolving needs of various sectors, including automotive, aerospace, construction, and consumer goods. The Global Mold Release Sealer Market's growth underscores its importance in modern manufacturing, where precision, quality, and efficiency are paramount. As the market continues to evolve, it will play a crucial role in supporting the development of innovative products and sustainable manufacturing practices.

| Report Metric | Details |

| Report Name | Mold Release Sealer Market |

| Accounted market size in year | US$ 2354 million |

| Forecasted market size in 2031 | US$ 3566 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Miller-Stephenson, Miracle Gloss, Polytek, Fiberlock, Pro's Choice, ProRestore, Sentinel, Stoner Molding Solutions, Henkel Adhesives, AXEL Plastics, Harger Lightning Protection |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |