What is Global Flame Retardant Conformal Coating Market?

The Global Flame Retardant Conformal Coating Market is a specialized segment within the broader coatings industry, focusing on providing protective layers to electronic components and assemblies. These coatings are designed to prevent fires by inhibiting the ignition and spread of flames, which is crucial in safeguarding sensitive electronic devices. The market has gained significant traction due to the increasing demand for electronic devices across various sectors, including consumer electronics, automotive, medical, and aerospace. Flame retardant conformal coatings are essential in ensuring the reliability and longevity of electronic components by protecting them from environmental factors such as moisture, dust, and chemicals. The coatings are typically applied in thin layers and conform to the contours of the electronic components, providing a seamless protective barrier. The market is driven by technological advancements and the growing emphasis on safety standards and regulations across industries. As electronic devices become more complex and integrated into everyday life, the need for effective flame retardant solutions continues to rise, making this market a critical component of the global electronics industry.

Acrylic, Epoxy, Silicone, Others in the Global Flame Retardant Conformal Coating Market:

In the Global Flame Retardant Conformal Coating Market, various types of coatings are utilized, each with distinct properties and applications. Acrylic coatings are widely used due to their ease of application and removal, making them ideal for environments where rework and repair are frequent. They offer excellent moisture resistance and dielectric properties, which are crucial for protecting electronic components. However, their flame retardant capabilities may not be as robust as other types, necessitating additional additives or formulations to enhance their performance in high-risk environments. Epoxy coatings, on the other hand, are known for their superior chemical and abrasion resistance. They provide a durable protective layer that is highly effective in harsh environments, making them suitable for industrial applications. Epoxy coatings are often used in situations where long-term protection is required, although their rigidity can be a drawback in applications where flexibility is needed. Silicone coatings offer excellent thermal stability and flexibility, making them ideal for applications involving extreme temperatures and thermal cycling. They provide a high level of protection against moisture and corrosion, which is essential in aerospace and automotive industries. Silicone coatings are also known for their excellent dielectric properties, making them suitable for high-voltage applications. However, their cost can be higher compared to other types of coatings. Other types of flame retardant conformal coatings include polyurethane and hybrid coatings, which combine the properties of different materials to achieve specific performance characteristics. Polyurethane coatings offer good abrasion resistance and flexibility, making them suitable for dynamic environments. Hybrid coatings are designed to provide a balance of properties, such as combining the flexibility of silicone with the chemical resistance of epoxy, to meet the specific needs of various applications. The choice of coating type depends on several factors, including the operating environment, the level of protection required, and cost considerations. As the demand for electronic devices continues to grow, the development of advanced flame retardant conformal coatings that offer enhanced performance and sustainability is expected to drive innovation in this market.

Consumer Electronics, Automotive, Medical, Aerospace, Others in the Global Flame Retardant Conformal Coating Market:

The usage of Global Flame Retardant Conformal Coating Market spans across several key industries, each with unique requirements and challenges. In the consumer electronics sector, these coatings are essential for protecting devices such as smartphones, tablets, and laptops from environmental damage and fire hazards. As consumer electronics become more compact and feature-rich, the need for reliable flame retardant solutions becomes increasingly important to ensure device safety and performance. In the automotive industry, flame retardant conformal coatings are used to protect electronic components in vehicles, such as sensors, control units, and infotainment systems. With the rise of electric and autonomous vehicles, the demand for advanced coatings that can withstand harsh automotive environments and provide reliable protection against fire risks is growing. In the medical field, these coatings are used to protect sensitive electronic equipment and devices, such as imaging systems and diagnostic tools, from moisture and contamination. The coatings help ensure the reliability and accuracy of medical devices, which is critical for patient safety and care. In the aerospace industry, flame retardant conformal coatings are used to protect electronic systems in aircraft and spacecraft from extreme temperatures, moisture, and vibration. The coatings play a vital role in ensuring the safety and reliability of aerospace systems, which operate in some of the most challenging environments. Other industries, such as telecommunications and industrial automation, also rely on flame retardant conformal coatings to protect their electronic components and systems. As technology continues to advance and the demand for electronic devices grows, the importance of flame retardant conformal coatings in ensuring the safety and reliability of electronic systems across various industries cannot be overstated.

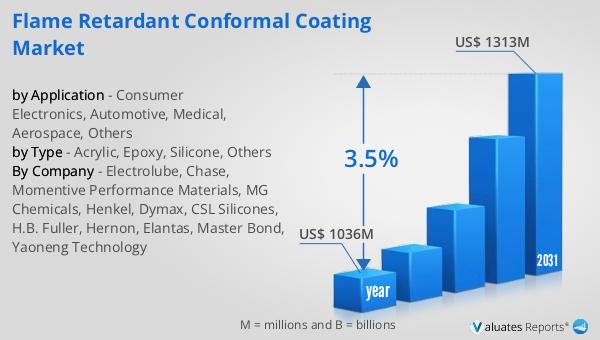

Global Flame Retardant Conformal Coating Market Outlook:

The global market for Flame Retardant Conformal Coating was valued at $1,036 million in 2024, with projections indicating it will grow to a revised size of $1,313 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.5% over the forecast period. This steady growth is driven by the increasing demand for electronic devices across various industries, coupled with the need for enhanced safety standards and regulations. As electronic devices become more integrated into everyday life, the importance of protecting these devices from fire hazards becomes paramount. Flame retardant conformal coatings play a crucial role in ensuring the safety and reliability of electronic components by providing a protective barrier against environmental factors and fire risks. The market's growth is also supported by technological advancements and the development of new coating formulations that offer improved performance and sustainability. As industries continue to prioritize safety and reliability, the demand for flame retardant conformal coatings is expected to remain strong, driving further innovation and growth in this market.

| Report Metric | Details |

| Report Name | Flame Retardant Conformal Coating Market |

| Accounted market size in year | US$ 1036 million |

| Forecasted market size in 2031 | US$ 1313 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Electrolube, Chase, Momentive Performance Materials, MG Chemicals, Henkel, Dymax, CSL Silicones, H.B. Fuller, Hernon, Elantas, Master Bond, Yaoneng Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |