What is Global Microporous Products for Aerospace Market?

The Global Microporous Products for Aerospace Market is a specialized segment within the aerospace industry that focuses on the development and application of microporous materials. These materials are characterized by their tiny pores, which provide exceptional insulation and thermal management properties. In the aerospace sector, microporous products are crucial for enhancing the performance and safety of various components and systems. They are used to manage heat and reduce weight, which are critical factors in aircraft design and operation. The market for these products is driven by the increasing demand for fuel-efficient and lightweight aircraft, as well as the need for advanced thermal management solutions. As aerospace technology continues to evolve, the role of microporous materials becomes even more significant, offering innovative solutions to meet the stringent requirements of modern aircraft. The market is expected to grow as manufacturers and engineers seek to leverage the unique properties of microporous materials to improve the efficiency and safety of aerospace systems.

Board, Rigid Panel, Flexible Panel in the Global Microporous Products for Aerospace Market:

In the Global Microporous Products for Aerospace Market, products are often categorized into board, rigid panel, and flexible panel types, each serving distinct purposes and applications. Board-type microporous products are typically used in areas where structural integrity and high thermal insulation are required. These boards are often employed in engine compartments and other high-temperature zones within an aircraft. They provide excellent thermal resistance, helping to protect sensitive components from extreme heat. The rigidity of these boards ensures they maintain their shape and effectiveness even under challenging conditions. Rigid panels, on the other hand, are designed to offer a balance between structural support and thermal insulation. They are commonly used in areas where both strength and insulation are necessary, such as in the construction of aircraft fuselages and wings. These panels are engineered to withstand significant mechanical stress while providing superior thermal management. Their application is crucial in maintaining the structural integrity of the aircraft while ensuring that temperature-sensitive components are adequately protected. Flexible panels are another vital category within the microporous products market. These panels are designed to conform to various shapes and surfaces, making them ideal for use in complex and irregularly shaped areas of an aircraft. They are often used in insulation blankets and other applications where flexibility and adaptability are essential. The ability of these panels to fit snugly around components ensures that there are no gaps in insulation, providing comprehensive thermal protection. The versatility of flexible panels makes them a popular choice for a wide range of aerospace applications, from insulating ducts and pipes to protecting electronic components. Each type of microporous product offers unique advantages, and the choice between board, rigid panel, and flexible panel depends on the specific requirements of the application. As the aerospace industry continues to advance, the demand for these specialized materials is expected to grow, driven by the need for improved thermal management and lightweight solutions. Manufacturers are continually innovating to enhance the performance and capabilities of these products, ensuring they meet the evolving needs of the aerospace sector.

Auxillary Power Units, Flight or Critical Data Recorders, Bleed Air and De-icing Ducts in the Global Microporous Products for Aerospace Market:

Microporous products play a crucial role in various aerospace applications, particularly in auxiliary power units (APUs), flight or critical data recorders, bleed air, and de-icing ducts. In auxiliary power units, microporous materials are used to provide thermal insulation and reduce noise. APUs are essential for providing power to aircraft systems when the main engines are not running, and they generate significant heat during operation. Microporous insulation helps manage this heat, ensuring the APU operates efficiently and safely. Additionally, the noise-reducing properties of these materials contribute to a quieter cabin environment, enhancing passenger comfort. In flight or critical data recorders, commonly known as black boxes, microporous products are used to protect sensitive electronic components from extreme temperatures and impact forces. These recorders are designed to withstand the harshest conditions, including high-impact crashes and intense fires. The thermal insulation provided by microporous materials ensures that the data stored within these devices remains intact, even in the most challenging scenarios. This is vital for accident investigations and improving aviation safety. Bleed air systems, which extract air from the engines to power various aircraft systems, also benefit from microporous insulation. The high temperatures of bleed air require effective thermal management to prevent damage to surrounding components and ensure efficient system operation. Microporous materials provide the necessary insulation, maintaining the integrity and performance of the bleed air system. In de-icing ducts, microporous products are used to prevent the formation of ice on critical aircraft surfaces. Ice accumulation can significantly impact an aircraft's performance and safety, making effective de-icing systems essential. Microporous insulation helps maintain the temperature of de-icing ducts, ensuring they function effectively in preventing ice build-up. The use of microporous products in these applications highlights their importance in enhancing the safety, efficiency, and performance of modern aircraft. As the aerospace industry continues to evolve, the demand for advanced thermal management solutions like microporous materials is expected to grow, driven by the need for improved safety and efficiency.

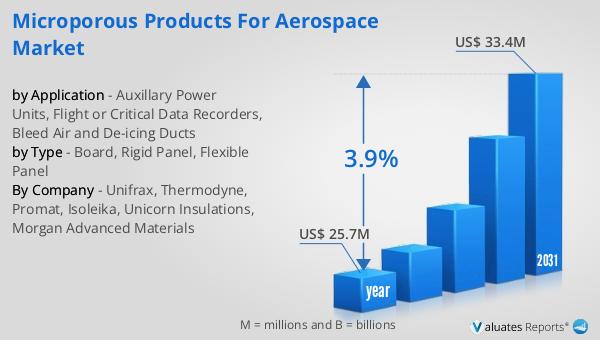

Global Microporous Products for Aerospace Market Outlook:

The global market for microporous products in the aerospace sector was valued at $25.7 million in 2024. This market is anticipated to expand, reaching an estimated size of $33.4 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.9% over the forecast period. The increasing demand for lightweight and fuel-efficient aircraft is a significant driver of this market growth. As airlines and manufacturers strive to reduce operational costs and environmental impact, the adoption of advanced materials like microporous products becomes increasingly important. These materials offer exceptional thermal insulation and weight reduction capabilities, making them ideal for modern aerospace applications. The projected growth of the microporous products market reflects the broader trends in the aerospace industry, where innovation and efficiency are paramount. As new technologies and materials continue to emerge, the role of microporous products in enhancing aircraft performance and safety is expected to become even more critical. This market outlook underscores the importance of continued research and development in the field of microporous materials, as manufacturers seek to meet the evolving needs of the aerospace sector.

| Report Metric | Details |

| Report Name | Microporous Products for Aerospace Market |

| Accounted market size in year | US$ 25.7 million |

| Forecasted market size in 2031 | US$ 33.4 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Unifrax, Thermodyne, Promat, Isoleika, Unicorn Insulations, Morgan Advanced Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |