What is Global Metallurgical Grade Fluorite Fine Powder Market?

The Global Metallurgical Grade Fluorite Fine Powder Market is a specialized segment within the broader fluorite industry, focusing on the production and distribution of fine powder fluorite used primarily in metallurgical applications. Fluorite, also known as fluorspar, is a mineral composed of calcium fluoride and is a critical raw material in various industrial processes. The metallurgical grade of fluorite is particularly important in the steelmaking industry, where it is used as a flux to remove impurities such as sulfur and phosphorus from molten metal, thereby improving the quality and durability of the steel. This market is driven by the demand for high-quality steel and other metals, which in turn fuels the need for efficient and effective fluxing agents. The fine powder form of metallurgical grade fluorite is preferred for its ease of handling and superior performance in metallurgical processes. As industries continue to seek ways to enhance production efficiency and product quality, the demand for metallurgical grade fluorite fine powder is expected to remain robust. This market is characterized by a diverse range of suppliers and manufacturers, each offering products with varying levels of purity and particle size to meet the specific needs of different industrial applications.

Purity: Below 90%, Purity: 90%-85%, Purity: Above 95% in the Global Metallurgical Grade Fluorite Fine Powder Market:

In the Global Metallurgical Grade Fluorite Fine Powder Market, purity levels play a crucial role in determining the suitability and effectiveness of the product for various applications. The purity of fluorite is typically categorized into three main levels: below 90%, 90%-95%, and above 95%. Each of these purity levels has distinct characteristics and applications. Fluorite with a purity level below 90% is generally considered lower grade and is often used in applications where the presence of impurities does not significantly impact the end product. This grade is typically more affordable and is used in less demanding industrial processes. On the other hand, fluorite with a purity level of 90%-95% is considered medium grade and is suitable for a wider range of applications. This grade offers a balance between cost and performance, making it a popular choice for many industries. It is often used in the production of aluminum, where it acts as a flux to lower the melting point of the raw materials and improve the efficiency of the smelting process. The highest purity level, above 95%, is considered premium grade and is used in applications where the highest quality and performance are required. This grade is often used in the production of high-quality steel and other metals, where even small amounts of impurities can significantly impact the final product. The high purity level ensures that the fluorite performs its role as a flux effectively, removing impurities and improving the quality of the metal. In addition to its use in metallurgy, high-purity fluorite is also used in the production of hydrofluoric acid, which is a key raw material in the chemical industry. The demand for high-purity fluorite is driven by the need for high-quality end products and the increasing focus on efficiency and sustainability in industrial processes. As industries continue to evolve and demand higher quality materials, the importance of purity in the Global Metallurgical Grade Fluorite Fine Powder Market is expected to grow. Manufacturers and suppliers in this market are continually working to improve the purity and performance of their products to meet the changing needs of their customers. This focus on purity and quality is a key factor driving the growth and development of the Global Metallurgical Grade Fluorite Fine Powder Market.

Metallurgy, Industrial, Others in the Global Metallurgical Grade Fluorite Fine Powder Market:

The Global Metallurgical Grade Fluorite Fine Powder Market finds its applications in various sectors, with metallurgy being one of the primary areas of use. In the field of metallurgy, fluorite fine powder is used as a fluxing agent to remove impurities from molten metal. This process is crucial in the production of high-quality steel and other metals, as it helps to improve the durability and performance of the final product. The fine powder form of fluorite is particularly effective in this application, as it allows for even distribution and efficient removal of impurities. In addition to its use in steelmaking, fluorite fine powder is also used in the production of aluminum, where it helps to lower the melting point of the raw materials and improve the efficiency of the smelting process. The industrial sector also relies on metallurgical grade fluorite fine powder for a variety of applications. In the chemical industry, fluorite is used in the production of hydrofluoric acid, which is a key raw material for the manufacture of a wide range of products, including refrigerants, pharmaceuticals, and plastics. The high purity and fine particle size of metallurgical grade fluorite make it an ideal choice for this application, as it ensures the production of high-quality hydrofluoric acid. Additionally, fluorite fine powder is used in the glass and ceramics industries, where it acts as a flux to improve the melting properties of the raw materials and enhance the quality of the final product. Beyond metallurgy and industrial applications, metallurgical grade fluorite fine powder is also used in other areas, such as environmental protection and agriculture. In environmental protection, fluorite is used in the treatment of wastewater, where it helps to remove heavy metals and other contaminants. This application is becoming increasingly important as industries seek to reduce their environmental impact and comply with stricter regulations. In agriculture, fluorite is used as a soil conditioner to improve the quality and fertility of the soil. The fine powder form of fluorite is particularly effective in this application, as it allows for even distribution and efficient absorption by the soil. Overall, the versatility and effectiveness of metallurgical grade fluorite fine powder make it a valuable resource in a wide range of applications. As industries continue to evolve and demand higher quality materials, the importance of fluorite in the Global Metallurgical Grade Fluorite Fine Powder Market is expected to grow.

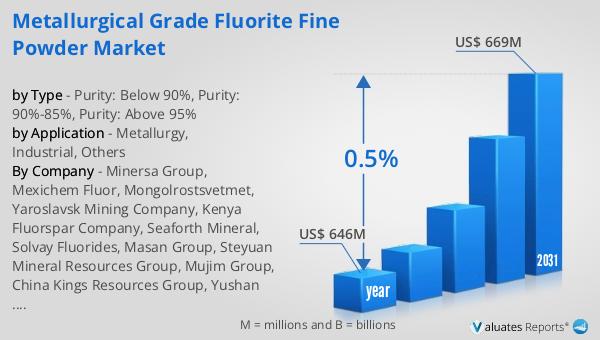

Global Metallurgical Grade Fluorite Fine Powder Market Outlook:

The global market for Metallurgical Grade Fluorite Fine Powder was valued at $646 million in 2024, with projections indicating a growth to $669 million by 2031, reflecting a compound annual growth rate (CAGR) of 0.5% over the forecast period. This market outlook highlights a steady, albeit modest, growth trajectory, driven by the ongoing demand for high-quality metallurgical products and the critical role of fluorite as a fluxing agent in various industrial processes. The market's valuation underscores the importance of metallurgical grade fluorite fine powder in the production of steel, aluminum, and other metals, where it is used to remove impurities and enhance the quality of the final product. Despite the relatively slow growth rate, the market's stability is indicative of the consistent demand for metallurgical grade fluorite fine powder across different industries. This demand is fueled by the need for efficient and effective fluxing agents that can improve production efficiency and product quality. As industries continue to prioritize sustainability and efficiency, the role of metallurgical grade fluorite fine powder in achieving these goals is expected to remain significant. The market's growth is also supported by advancements in production technologies and the increasing focus on purity and quality in the Global Metallurgical Grade Fluorite Fine Powder Market.

| Report Metric | Details |

| Report Name | Metallurgical Grade Fluorite Fine Powder Market |

| Accounted market size in year | US$ 646 million |

| Forecasted market size in 2031 | US$ 669 million |

| CAGR | 0.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Minersa Group, Mexichem Fluor, Mongolrostsvetmet, Yaroslavsk Mining Company, Kenya Fluorspar Company, Seaforth Mineral, Solvay Fluorides, Masan Group, Steyuan Mineral Resources Group, Mujim Group, China Kings Resources Group, Yushan Fengyuan Fluoride Chemical, Wuyi Shenlong Flotation, Inner Mongolia Xiang Zhen Mining, Hunan Nonferrous Chenzhou Fluoride |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |