What is Global High-end Polyolefin Elastomer Market?

The Global High-end Polyolefin Elastomer Market is a specialized segment within the broader elastomer industry, focusing on high-performance materials known for their flexibility, durability, and resistance to various environmental factors. Polyolefin elastomers (POEs) are a type of polymer that combines the properties of rubber and plastic, making them highly versatile for numerous applications. These materials are particularly valued for their ability to maintain elasticity over a wide temperature range, which makes them suitable for use in extreme conditions. The high-end segment of this market refers to POEs that offer superior performance characteristics, such as enhanced tensile strength, improved impact resistance, and better chemical stability. These advanced materials are increasingly in demand across various industries, including automotive, packaging, and renewable energy, due to their ability to improve product performance and longevity. As industries continue to seek materials that offer both functionality and sustainability, the Global High-end Polyolefin Elastomer Market is poised for growth, driven by technological advancements and the increasing need for high-performance materials in demanding applications. The market's expansion is further supported by ongoing research and development efforts aimed at enhancing the properties and applications of these elastomers.

Injection Grade, General Grade, Extrusion Grade, Others in the Global High-end Polyolefin Elastomer Market:

In the Global High-end Polyolefin Elastomer Market, different grades of elastomers are tailored to meet specific application requirements, each offering unique properties that make them suitable for various industrial uses. Injection Grade polyolefin elastomers are designed for applications that require precision molding and high dimensional stability. These elastomers are ideal for producing complex shapes and intricate designs, often used in the automotive and consumer goods industries. Their ability to flow easily during the injection molding process allows for the creation of detailed components with minimal defects, making them a preferred choice for manufacturers seeking high-quality finishes and reliable performance. General Grade polyolefin elastomers, on the other hand, offer a balance of properties suitable for a wide range of applications. These elastomers are versatile and can be used in products that require moderate flexibility and durability, such as household goods, toys, and certain types of packaging. Their cost-effectiveness and ease of processing make them a popular choice for manufacturers looking to optimize production without compromising on quality. Extrusion Grade polyolefin elastomers are specifically formulated for applications that involve the extrusion process, where materials are forced through a die to create long, continuous shapes. These elastomers are used in the production of films, sheets, and profiles, offering excellent processability and surface finish. Their ability to maintain consistent properties during the extrusion process makes them ideal for applications in the construction and packaging industries, where uniformity and strength are critical. Other grades of polyolefin elastomers include those designed for specific niche applications, such as medical devices, electrical insulation, and adhesives. These specialized elastomers are engineered to meet stringent regulatory requirements and offer unique properties tailored to their intended use. For instance, medical-grade elastomers must be biocompatible and able to withstand sterilization processes, while elastomers used in electrical applications need to provide excellent insulation and resistance to environmental factors. The diversity of grades within the Global High-end Polyolefin Elastomer Market highlights the material's adaptability and the industry's commitment to meeting the evolving needs of various sectors. As technology advances and new applications emerge, the development of specialized grades will continue to play a crucial role in the market's growth, offering innovative solutions to complex challenges across industries.

Automobile, Photovoltaic, Packaging, Others in the Global High-end Polyolefin Elastomer Market:

The Global High-end Polyolefin Elastomer Market finds extensive usage across various sectors, each benefiting from the unique properties of these advanced materials. In the automobile industry, high-end polyolefin elastomers are used to manufacture components that require a combination of flexibility, durability, and resistance to harsh environmental conditions. These elastomers are commonly found in automotive interiors, such as dashboards and door panels, where they provide a soft-touch feel and enhance the overall aesthetic appeal. Additionally, their ability to withstand temperature fluctuations and resist wear and tear makes them ideal for under-the-hood applications, such as hoses and seals, where performance and reliability are paramount. In the photovoltaic sector, high-end polyolefin elastomers play a crucial role in the production of solar panels. These materials are used as encapsulants, providing protection to the delicate solar cells from moisture, UV radiation, and mechanical stress. The elastomers' excellent transparency and adhesion properties ensure maximum light transmission and long-term durability, contributing to the efficiency and lifespan of solar panels. As the demand for renewable energy continues to rise, the use of high-end polyolefin elastomers in photovoltaic applications is expected to grow, driven by the need for sustainable and efficient energy solutions. In the packaging industry, high-end polyolefin elastomers are valued for their ability to create flexible, durable, and lightweight packaging solutions. These materials are used in the production of films, bags, and containers, offering excellent sealability and resistance to punctures and tears. Their versatility allows for the creation of packaging that can withstand various environmental conditions, ensuring the protection and preservation of goods during storage and transportation. The growing emphasis on sustainability and the reduction of plastic waste has also led to the development of biodegradable and recyclable polyolefin elastomer-based packaging, aligning with global efforts to promote environmentally friendly practices. Beyond these sectors, high-end polyolefin elastomers are used in a variety of other applications, including medical devices, consumer electronics, and construction materials. In the medical field, these elastomers are used to produce flexible and durable components, such as tubing and seals, that meet stringent regulatory standards for safety and performance. In consumer electronics, they provide impact resistance and aesthetic appeal to products like smartphone cases and wearable devices. In construction, high-end polyolefin elastomers are used in roofing membranes and sealants, offering weather resistance and long-term durability. The diverse applications of high-end polyolefin elastomers underscore their importance in modern industry, providing innovative solutions that enhance product performance and sustainability across multiple sectors.

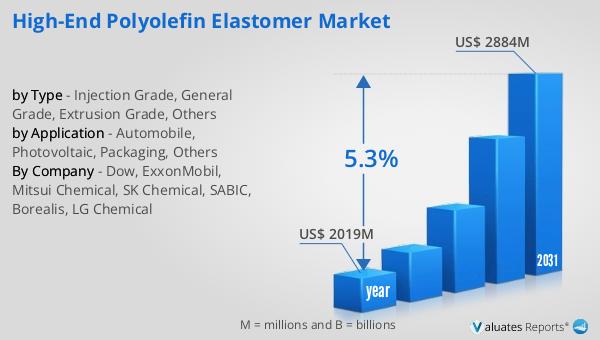

Global High-end Polyolefin Elastomer Market Outlook:

The outlook for the Global High-end Polyolefin Elastomer Market is promising, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately $2,019 million, reflecting the increasing demand for high-performance materials across various industries. By 2031, the market is projected to reach a revised size of $2,884 million, driven by a compound annual growth rate (CAGR) of 5.3% during the forecast period. This growth trajectory highlights the expanding applications and technological advancements in the field of polyolefin elastomers, as industries continue to seek materials that offer both functionality and sustainability. The automotive, packaging, and renewable energy sectors are expected to be key drivers of this growth, as they increasingly adopt high-end polyolefin elastomers to enhance product performance and meet evolving consumer demands. Additionally, ongoing research and development efforts aimed at improving the properties and applications of these elastomers are likely to contribute to the market's expansion, offering innovative solutions to complex challenges across industries. As the market continues to evolve, the Global High-end Polyolefin Elastomer Market is poised to play a crucial role in shaping the future of materials science, providing advanced materials that meet the needs of a rapidly changing world.

| Report Metric | Details |

| Report Name | High-end Polyolefin Elastomer Market |

| Accounted market size in year | US$ 2019 million |

| Forecasted market size in 2031 | US$ 2884 million |

| CAGR | 5.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dow, ExxonMobil, Mitsui Chemical, SK Chemical, SABIC, Borealis, LG Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |