What is Global LED Packaging Material Market?

The Global LED Packaging Material Market is a crucial segment within the broader LED industry, focusing on the materials used to encase and protect LED components. These materials are essential for ensuring the durability, efficiency, and performance of LED products. The market encompasses a variety of materials, including epoxy resins, silicones, ceramics, and metals, each serving specific functions in the packaging process. The primary role of these materials is to safeguard the LED chips from environmental factors such as moisture, heat, and physical damage, thereby extending their lifespan and maintaining their luminous efficacy. Additionally, these materials play a significant role in heat dissipation, which is critical for the optimal functioning of LEDs. The demand for LED packaging materials is driven by the increasing adoption of LEDs in various applications, such as lighting, displays, and automotive sectors, due to their energy efficiency and long lifespan. As technology advances, the market continues to evolve, with innovations aimed at enhancing the performance and cost-effectiveness of LED packaging solutions. This dynamic market is characterized by ongoing research and development efforts to improve material properties and meet the growing demands of the LED industry.

Epoxy Resin, Silicone in the Global LED Packaging Material Market:

Epoxy resin and silicone are two pivotal materials in the Global LED Packaging Material Market, each offering unique properties that cater to specific needs in LED packaging. Epoxy resin is widely used due to its excellent adhesive properties, mechanical strength, and resistance to environmental factors. It provides a robust protective layer that shields LED components from moisture, dust, and mechanical stress, ensuring their longevity and reliability. Epoxy resins are particularly favored in applications where cost-effectiveness is a priority, as they offer a balance between performance and affordability. However, they have limitations in terms of thermal management, as they are not as effective in dissipating heat compared to other materials. On the other hand, silicone is renowned for its superior thermal stability and flexibility, making it an ideal choice for high-performance LED applications. Silicone materials can withstand extreme temperatures and maintain their properties over a wide range of environmental conditions, which is crucial for LEDs that operate in demanding settings. Their excellent thermal conductivity aids in efficient heat dissipation, preventing overheating and enhancing the overall performance of LED devices. Moreover, silicone's flexibility allows for innovative design possibilities, enabling the creation of complex shapes and structures that can accommodate various LED configurations. Despite being more expensive than epoxy resins, silicone's advantages in terms of durability and performance make it a preferred choice for premium LED applications. The choice between epoxy resin and silicone in LED packaging often depends on the specific requirements of the application, such as cost constraints, environmental conditions, and performance expectations. As the LED industry continues to grow and diversify, the demand for both epoxy resin and silicone is expected to rise, driven by the need for reliable and efficient packaging solutions that can meet the evolving demands of modern LED technologies. Manufacturers are continually exploring new formulations and processing techniques to enhance the properties of these materials, aiming to achieve a balance between cost, performance, and sustainability. This ongoing innovation is crucial for maintaining the competitiveness of the Global LED Packaging Material Market and supporting the widespread adoption of LED technologies across various sectors.

LED Display, LED Backlight in the Global LED Packaging Material Market:

The usage of Global LED Packaging Material Market in areas such as LED Display and LED Backlight is significant, as these applications demand high-performance materials that can ensure the reliability and efficiency of LED products. In LED displays, packaging materials play a crucial role in protecting the delicate LED chips from environmental factors and mechanical stress. The materials used must provide excellent optical clarity to ensure that the light emitted by the LEDs is not distorted, maintaining the quality and brightness of the display. Epoxy resins and silicones are commonly used in this context, with silicones being preferred for high-end displays due to their superior thermal management and flexibility. The ability of silicone to withstand high temperatures and maintain its properties over time makes it ideal for displays that require consistent performance and longevity. In LED backlighting, packaging materials are equally important, as they contribute to the uniform distribution of light across the display surface. This is particularly crucial in applications such as televisions, monitors, and mobile devices, where even light distribution is essential for optimal viewing experiences. The materials used in LED backlighting must also offer excellent thermal conductivity to prevent overheating and ensure the longevity of the LEDs. Silicone's superior thermal properties make it a popular choice for backlighting applications, as it can effectively dissipate heat and maintain the performance of the LEDs. Additionally, the flexibility of silicone allows for innovative design possibilities, enabling manufacturers to create thinner and more efficient backlighting solutions. As the demand for high-quality displays and backlighting solutions continues to grow, the Global LED Packaging Material Market is expected to play a pivotal role in supporting the development of advanced LED technologies. Manufacturers are continually exploring new materials and processing techniques to enhance the performance and cost-effectiveness of LED packaging solutions, ensuring that they can meet the evolving demands of the display and backlighting industries. This ongoing innovation is crucial for maintaining the competitiveness of the LED market and supporting the widespread adoption of LED technologies across various sectors.

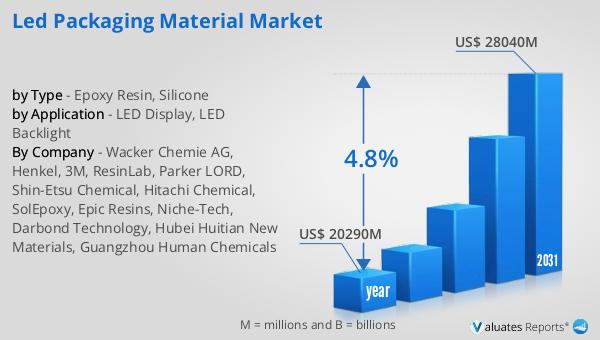

Global LED Packaging Material Market Outlook:

The global market for LED Packaging Material was valued at approximately $20,290 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $28,040 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.8% over the forecast period. The steady increase in market size reflects the rising demand for LED technologies across various applications, driven by their energy efficiency, long lifespan, and environmental benefits. As industries continue to adopt LED solutions for lighting, displays, and automotive applications, the need for high-quality packaging materials becomes increasingly critical. These materials are essential for ensuring the durability, performance, and reliability of LED products, protecting them from environmental factors and mechanical stress. The market's growth is also fueled by ongoing innovations in material science, as manufacturers strive to develop more efficient and cost-effective packaging solutions. This dynamic market environment presents numerous opportunities for companies involved in the production and supply of LED packaging materials, as they work to meet the evolving demands of the LED industry and support the widespread adoption of LED technologies worldwide.

| Report Metric | Details |

| Report Name | LED Packaging Material Market |

| Accounted market size in year | US$ 20290 million |

| Forecasted market size in 2031 | US$ 28040 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Wacker Chemie AG, Henkel, 3M, ResinLab, Parker LORD, Shin-Etsu Chemical, Hitachi Chemical, SolEpoxy, Epic Resins, Niche-Tech, Darbond Technology, Hubei Huitian New Materials, Guangzhou Human Chemicals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |