What is Global Interior Can Coating Market?

The Global Interior Can Coating Market is a specialized segment within the broader coatings industry, focusing on the application of protective and decorative coatings to the interior surfaces of metal cans. These coatings are crucial for maintaining the integrity and safety of the contents, whether they are beverages, food, or other products. The coatings prevent the metal from corroding and reacting with the can's contents, which could otherwise lead to contamination or spoilage. The market is driven by the increasing demand for canned products, which offer convenience and extended shelf life. Additionally, there is a growing emphasis on sustainability and the use of eco-friendly materials, which is influencing the development of new coating technologies. The market is characterized by a variety of coating types, including epoxy, polyester, and acrylic, each offering distinct properties and benefits. As consumer preferences evolve and regulatory standards become more stringent, the Global Interior Can Coating Market continues to innovate, ensuring that products remain safe and appealing to consumers. This market is a vital component of the packaging industry, supporting the global supply chain by ensuring that canned goods are delivered safely and efficiently to consumers worldwide.

Epoxy, Polyester, Acrylic in the Global Interior Can Coating Market:

Epoxy, polyester, and acrylic coatings are the primary types of materials used in the Global Interior Can Coating Market, each offering unique properties that cater to different needs and applications. Epoxy coatings are widely used due to their excellent adhesion, chemical resistance, and durability. They form a tough, protective layer that can withstand the rigors of canning processes and the acidic or alkaline nature of various food and beverage products. Epoxy coatings are particularly favored in the beverage industry, where they help maintain the taste and quality of the contents by preventing metal leaching. However, concerns about bisphenol A (BPA), a component of some epoxy resins, have led to increased research and development of BPA-free alternatives. Polyester coatings, on the other hand, are known for their flexibility and resistance to cracking, making them suitable for applications where the can undergoes significant deformation during processing or handling. They offer good chemical resistance and are often used in food cans where the contents are less aggressive. Polyester coatings are also valued for their aesthetic properties, providing a glossy finish that enhances the visual appeal of the can. Acrylic coatings are another option, prized for their clarity and resistance to yellowing over time. They are often used in applications where the appearance of the can is a critical factor, such as in premium or specialty products. Acrylic coatings provide a high level of protection against UV light and oxidation, ensuring that the contents remain fresh and untainted. Each of these coating types plays a crucial role in the Global Interior Can Coating Market, offering manufacturers a range of options to meet the diverse needs of their products and consumers. As the market evolves, there is a continuous push towards developing coatings that are not only effective but also environmentally friendly, aligning with global sustainability goals. This has led to innovations in water-based and solvent-free coatings, which reduce volatile organic compound (VOC) emissions and minimize environmental impact. The choice of coating material depends on various factors, including the type of product being canned, the processing conditions, and regulatory requirements. Manufacturers must carefully consider these factors to ensure that their coatings provide the necessary protection and performance while also meeting consumer expectations and regulatory standards. The ongoing advancements in coating technology are a testament to the dynamic nature of the Global Interior Can Coating Market, as it adapts to changing consumer preferences and environmental considerations.

Beverage Can, Food Can, Other in the Global Interior Can Coating Market:

The Global Interior Can Coating Market finds its application across various sectors, with beverage cans, food cans, and other types of cans being the primary areas of usage. In the beverage can segment, interior coatings are essential for preserving the taste and quality of the drinks. These coatings prevent the metal from interacting with the beverage, which could otherwise lead to off-flavors or contamination. The coatings also provide a barrier against carbonation loss, ensuring that carbonated drinks remain fizzy and refreshing. The demand for canned beverages, including soft drinks, energy drinks, and alcoholic beverages, continues to drive the need for high-performance interior can coatings. In the food can segment, coatings play a critical role in maintaining the safety and quality of canned foods. They protect the metal from corrosion and prevent the leaching of metal ions into the food, which could affect its taste and safety. The coatings must withstand the high temperatures and pressures of the canning process, as well as the acidic or alkaline nature of various food products. This requires coatings that are not only durable but also compliant with food safety regulations. The increasing demand for convenience foods and ready-to-eat meals has further fueled the growth of the food can segment within the Global Interior Can Coating Market. Beyond beverages and food, interior can coatings are also used in other applications, such as aerosol cans and industrial containers. In these cases, the coatings provide a protective barrier that prevents the contents from reacting with the metal, ensuring the product's stability and effectiveness. For instance, in aerosol cans, the coatings must be resistant to the propellants and solvents used in the formulation, while also providing a smooth surface for the product to be dispensed evenly. The versatility of interior can coatings makes them indispensable across a wide range of industries, supporting the safe and efficient packaging of products. As consumer preferences shift towards more sustainable and environmentally friendly packaging solutions, the Global Interior Can Coating Market is also evolving to meet these demands. This includes the development of coatings that are free from harmful substances, such as BPA, and the use of renewable or recycled materials in the coating formulations. The market's ability to adapt to these changes is crucial for its continued growth and relevance in the global packaging industry.

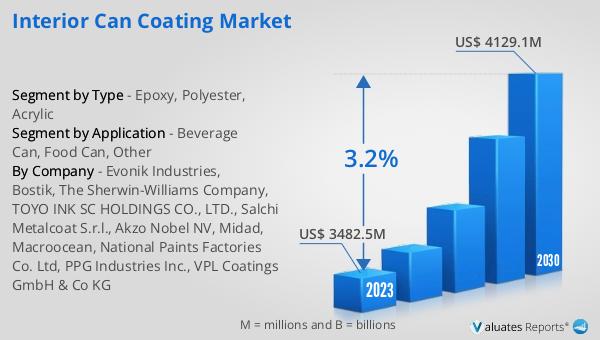

Global Interior Can Coating Market Outlook:

In 2024, the global market for Interior Can Coating was valued at approximately $3,516 million. This market is anticipated to expand, reaching an estimated size of $4,370 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.2% over the forecast period. The steady increase in market size reflects the rising demand for canned products across various sectors, including food, beverages, and other consumer goods. As the market evolves, manufacturers are focusing on developing innovative coating solutions that meet the changing needs of consumers and regulatory standards. This includes the creation of coatings that are not only effective in protecting the contents of the cans but also environmentally friendly and sustainable. The projected growth of the Global Interior Can Coating Market underscores the importance of these coatings in ensuring the safety, quality, and longevity of canned products. As consumer preferences continue to shift towards more sustainable and convenient packaging options, the demand for high-performance interior can coatings is expected to remain strong. This growth also highlights the ongoing advancements in coating technology, as manufacturers strive to develop solutions that address the challenges of modern packaging while also meeting the expectations of consumers and regulatory bodies. The market's ability to adapt to these changes is crucial for its continued success and relevance in the global packaging industry.

| Report Metric | Details |

| Report Name | Interior Can Coating Market |

| Accounted market size in year | US$ 3516 million |

| Forecasted market size in 2031 | US$ 4370 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Evonik Industries, Bostik, The Sherwin-Williams Company, TOYO INK SC HOLDINGS CO., LTD., Salchi Metalcoat S.r.l., Akzo Nobel NV, Midad, Macroocean, National Paints Factories Co. Ltd, PPG Industries Inc., VPL Coatings GmbH & Co KG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |