What is Global Hydrophobic Coating for Medical Devices Market?

Global hydrophobic coatings for medical devices are specialized surface treatments designed to repel water and other liquids. These coatings are crucial in the medical field because they help prevent the accumulation of bodily fluids and other contaminants on medical devices, thereby reducing the risk of infection and improving the longevity and performance of the devices. Hydrophobic coatings work by creating a surface that is highly resistant to moisture, which can be particularly beneficial in environments where sterility and cleanliness are paramount. These coatings are applied to a wide range of medical devices, including catheters, guide wires, and other instruments that come into contact with bodily fluids. By minimizing the adhesion of liquids, hydrophobic coatings help maintain the functionality and safety of medical devices, ensuring that they perform as intended in critical healthcare settings. The global market for these coatings is driven by the increasing demand for advanced medical devices and the need for improved infection control measures in healthcare facilities. As medical technology continues to evolve, the role of hydrophobic coatings in enhancing device performance and patient safety is expected to grow, making them an essential component of modern medical device manufacturing.

Polymers Substrate, Glass/Ceramics Substrate, Nanoparticles Substrate, Other in the Global Hydrophobic Coating for Medical Devices Market:

In the realm of global hydrophobic coatings for medical devices, substrates play a pivotal role in determining the effectiveness and application of these coatings. Polymers, glass/ceramics, nanoparticles, and other substrates each offer unique properties that make them suitable for different medical applications. Polymers are widely used as substrates due to their versatility and compatibility with various coating technologies. They are lightweight, flexible, and can be easily molded into complex shapes, making them ideal for a range of medical devices such as catheters and tubing. The hydrophobic coating on polymer substrates enhances their resistance to moisture and reduces friction, which is crucial for devices that need to navigate through the human body with minimal resistance. Glass and ceramics substrates, on the other hand, are known for their durability and resistance to high temperatures and chemical reactions. These properties make them suitable for medical devices that require sterilization and long-term use. The application of hydrophobic coatings on glass and ceramics helps prevent the accumulation of fluids and contaminants, ensuring that the devices remain clean and functional over extended periods. Nanoparticles substrates represent a more advanced approach, offering unique properties such as increased surface area and enhanced mechanical strength. These substrates can be engineered to provide specific functionalities, such as antimicrobial properties, which are highly beneficial in medical settings. The use of nanoparticles in hydrophobic coatings allows for the development of devices that are not only resistant to moisture but also capable of preventing bacterial growth, thereby reducing the risk of infections. Other substrates, including metals and composites, also play a role in the global hydrophobic coatings market. Metals are often used in surgical instruments and implants due to their strength and biocompatibility. The application of hydrophobic coatings on metal substrates helps reduce friction and wear, extending the lifespan of these devices. Composites, which combine the properties of different materials, offer a balance of strength, flexibility, and biocompatibility, making them suitable for a variety of medical applications. The choice of substrate in the global hydrophobic coatings market is influenced by factors such as the intended use of the medical device, the required properties of the coating, and the regulatory standards that must be met. As the demand for advanced medical devices continues to grow, the development of new substrates and coating technologies is expected to drive innovation in the market, leading to the creation of more effective and reliable medical devices.

Guide Wire, Catheter, Other in the Global Hydrophobic Coating for Medical Devices Market:

The global hydrophobic coating for medical devices market finds its application in various areas, including guide wires, catheters, and other medical instruments. Guide wires are essential tools in minimally invasive procedures, providing a pathway for the introduction of catheters and other devices into the body. The application of hydrophobic coatings on guide wires enhances their performance by reducing friction and improving maneuverability. This is particularly important in complex procedures where precision and control are critical. The hydrophobic coating ensures that the guide wire can navigate through the vascular system smoothly, minimizing the risk of damage to blood vessels and improving patient outcomes. Catheters, another key application area, benefit significantly from hydrophobic coatings. These flexible tubes are used to deliver fluids, medications, or to drain fluids from the body. The hydrophobic coating on catheters reduces the adhesion of bodily fluids and other contaminants, which helps maintain sterility and reduces the risk of infection. This is crucial in healthcare settings where infection control is a top priority. The coating also enhances the comfort and safety of the patient by reducing friction during insertion and removal. Other medical devices, such as stents, implants, and surgical instruments, also benefit from hydrophobic coatings. These coatings help maintain the cleanliness and functionality of the devices, ensuring that they perform as intended in critical medical procedures. For instance, surgical instruments coated with hydrophobic materials are easier to clean and sterilize, reducing the risk of cross-contamination between patients. Implants, which remain in the body for extended periods, benefit from hydrophobic coatings that prevent the accumulation of bodily fluids and reduce the risk of infection. The use of hydrophobic coatings in these areas highlights the importance of surface treatments in enhancing the performance and safety of medical devices. As the demand for minimally invasive procedures and advanced medical technologies continues to grow, the role of hydrophobic coatings in improving device performance and patient outcomes is expected to become increasingly significant.

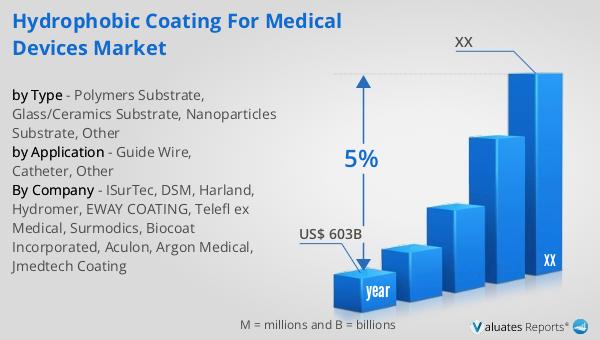

Global Hydrophobic Coating for Medical Devices Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including the increasing prevalence of chronic diseases, advancements in medical technology, and the rising demand for minimally invasive procedures. As healthcare systems worldwide strive to improve patient outcomes and reduce costs, the demand for innovative medical devices is expected to rise. Hydrophobic coatings play a crucial role in this market by enhancing the performance and safety of medical devices. These coatings help reduce the risk of infection, improve device longevity, and enhance patient comfort, making them an essential component of modern medical device manufacturing. The growing awareness of the benefits of hydrophobic coatings, coupled with the increasing demand for advanced medical devices, is expected to drive the growth of the global hydrophobic coatings market. As the market continues to evolve, manufacturers are likely to focus on developing new coating technologies and expanding their product offerings to meet the diverse needs of healthcare providers and patients. The global hydrophobic coatings market is poised for significant growth, driven by the increasing demand for advanced medical devices and the need for improved infection control measures in healthcare settings.

| Report Metric | Details |

| Report Name | Hydrophobic Coating for Medical Devices Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ISurTec, DSM, Harland, Hydromer, EWAY COATING, Telefl ex Medical, Surmodics, Biocoat Incorporated, Aculon, Argon Medical, Jmedtech Coating |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |