What is Global High Temperature Resistant Composite Resin Market?

The Global High Temperature Resistant Composite Resin Market is a specialized segment within the broader composite materials industry, focusing on resins that can withstand extreme temperatures without losing their structural integrity or performance. These resins are crucial in applications where materials are exposed to high heat, such as in aerospace, automotive, and industrial sectors. The market is driven by the increasing demand for lightweight and durable materials that can perform under harsh conditions. High temperature resistant composite resins are engineered to maintain their properties at elevated temperatures, making them ideal for use in environments where traditional materials would fail. The market is characterized by continuous innovation, with manufacturers investing in research and development to enhance the performance and cost-effectiveness of these resins. As industries strive for greater efficiency and sustainability, the demand for high temperature resistant composite resins is expected to grow, driven by their ability to reduce weight and improve fuel efficiency in transportation and aerospace applications. The market is also influenced by regulatory standards that require materials to meet specific performance criteria, further driving the adoption of advanced composite resins.

Polyimide Resin, Maleimide Resin, Cyanate Resin, Other in the Global High Temperature Resistant Composite Resin Market:

Polyimide resin is a key player in the Global High Temperature Resistant Composite Resin Market, known for its exceptional thermal stability, mechanical properties, and chemical resistance. These resins are often used in applications that require materials to withstand temperatures exceeding 260°C. Polyimide resins are particularly valued in the aerospace industry for their ability to maintain structural integrity under extreme conditions, making them ideal for components such as engine parts and heat shields. Their inherent flame retardancy and low smoke emission make them suitable for use in environments where safety is paramount. Maleimide resin, another important type, is recognized for its high glass transition temperature and excellent mechanical properties. These resins are often used in high-performance applications where materials are subjected to both high temperatures and mechanical stress. Maleimide resins are commonly found in the automotive and aerospace industries, where they contribute to the development of lightweight and durable components. Cyanate resin is known for its excellent thermal and mechanical properties, as well as its low moisture absorption. These resins are often used in electronic applications where high thermal stability and low dielectric loss are required. Cyanate resins are also used in the aerospace industry for their ability to withstand high temperatures and mechanical stress. Other types of high temperature resistant composite resins include phenolic resins, which are known for their excellent flame retardancy and thermal stability. These resins are often used in applications where fire resistance is critical, such as in the construction and transportation industries. Each type of resin offers unique properties that make them suitable for specific applications, and the choice of resin depends on the specific requirements of the application. The market for high temperature resistant composite resins is characterized by a wide range of products, each designed to meet the specific needs of different industries. Manufacturers are continually developing new formulations to enhance the performance and cost-effectiveness of these resins, driving innovation and growth in the market. As industries continue to demand materials that can withstand extreme conditions, the market for high temperature resistant composite resins is expected to expand, offering new opportunities for manufacturers and end-users alike.

Aerospace, Transportation, Electrical and Electronics, Other in the Global High Temperature Resistant Composite Resin Market:

The usage of Global High Temperature Resistant Composite Resin Market spans several critical industries, each benefiting from the unique properties of these advanced materials. In the aerospace sector, high temperature resistant composite resins are indispensable due to their ability to withstand the extreme conditions encountered during flight. These resins are used in the manufacturing of various aircraft components, including engine parts, heat shields, and structural components, where they contribute to weight reduction and improved fuel efficiency. The transportation industry also relies heavily on these resins, particularly in the automotive sector, where they are used to produce lightweight and durable components that can withstand high temperatures and mechanical stress. This is crucial for improving vehicle performance and fuel efficiency, as well as meeting stringent emissions standards. In the electrical and electronics industry, high temperature resistant composite resins are used in the production of components that require excellent thermal stability and low dielectric loss. These resins are essential for ensuring the reliability and performance of electronic devices, particularly in high-temperature environments. Other industries, such as construction and industrial manufacturing, also benefit from the use of these resins, particularly in applications where fire resistance and thermal stability are critical. The versatility and performance of high temperature resistant composite resins make them an attractive choice for a wide range of applications, driving their adoption across multiple industries. As technology continues to advance and industries seek more efficient and sustainable solutions, the demand for high temperature resistant composite resins is expected to grow, offering new opportunities for innovation and development.

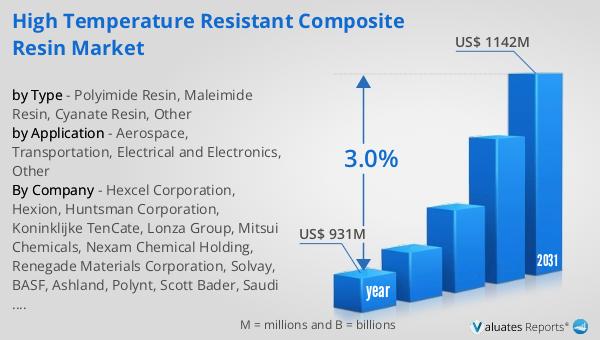

Global High Temperature Resistant Composite Resin Market Outlook:

In 2024, the global market for High Temperature Resistant Composite Resin was valued at approximately US$ 931 million. This market is anticipated to experience growth, reaching an estimated size of US$ 1142 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.0% over the forecast period. The steady increase in market size reflects the rising demand for materials that can withstand extreme temperatures across various industries. As industries such as aerospace, automotive, and electronics continue to evolve, the need for advanced materials that offer both durability and performance under high-temperature conditions becomes increasingly critical. The projected growth in the market is driven by the ongoing advancements in composite resin technology, as well as the increasing emphasis on sustainability and efficiency in industrial processes. The market's expansion is also supported by the growing adoption of high temperature resistant composite resins in emerging markets, where industrialization and technological advancements are driving demand for advanced materials. As the market continues to grow, manufacturers are expected to focus on developing innovative solutions that meet the evolving needs of end-users, further driving the adoption of high temperature resistant composite resins across various applications.

| Report Metric | Details |

| Report Name | High Temperature Resistant Composite Resin Market |

| Accounted market size in year | US$ 931 million |

| Forecasted market size in 2031 | US$ 1142 million |

| CAGR | 3.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hexcel Corporation, Hexion, Huntsman Corporation, Koninklijke TenCate, Lonza Group, Mitsui Chemicals, Nexam Chemical Holding, Renegade Materials Corporation, Solvay, BASF, Ashland, Polynt, Scott Bader, Saudi Basic Industries, Mader Composites |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |