What is Global Heavy Duty Vapour Barrier Coating Market?

The Global Heavy Duty Vapour Barrier Coating Market is a specialized segment within the broader coatings industry, focusing on products designed to prevent moisture penetration in various structures. These coatings are essential in protecting buildings and infrastructure from the damaging effects of water vapor, which can lead to structural deterioration, mold growth, and energy inefficiency. Heavy duty vapour barrier coatings are typically used in environments where high levels of moisture are present, such as basements, roofs, and industrial facilities. They are formulated to provide a robust barrier that can withstand harsh conditions and maintain their protective qualities over time. The market for these coatings is driven by the increasing demand for durable construction materials that enhance the longevity and performance of buildings. As construction practices evolve and the emphasis on sustainable building increases, the need for effective vapour barriers becomes more pronounced. This market is characterized by a variety of products tailored to different application methods and environmental conditions, ensuring that there is a suitable solution for every project requirement. The growth of this market is supported by advancements in coating technologies and a growing awareness of the importance of moisture management in construction.

Spray Grade, Trowel Grade, Airless Spray Grade in the Global Heavy Duty Vapour Barrier Coating Market:

In the Global Heavy Duty Vapour Barrier Coating Market, products are categorized based on their application methods, including Spray Grade, Trowel Grade, and Airless Spray Grade. Each type offers unique benefits and is suited to specific project needs. Spray Grade coatings are designed for application using spray equipment, making them ideal for large surface areas where speed and efficiency are crucial. This method allows for a uniform application, ensuring consistent coverage and thickness across the entire surface. Spray Grade coatings are often used in industrial settings where large-scale protection is required, such as on roofs or exterior walls. Trowel Grade coatings, on the other hand, are applied manually using a trowel, making them suitable for smaller areas or detailed work where precision is necessary. This method is often used in residential settings or for patching and repair work, where the ability to control the thickness and placement of the coating is important. Trowel Grade coatings are typically thicker and more viscous, providing a robust barrier that can withstand significant wear and tear. Airless Spray Grade coatings are applied using airless spray equipment, which allows for high-pressure application without the need for compressed air. This method is particularly effective for applying coatings to irregular surfaces or in hard-to-reach areas, as it can deliver a consistent and even coating regardless of the surface texture. Airless Spray Grade coatings are often used in commercial and industrial applications where a high level of protection is required, and the ability to cover complex geometries is essential. Each of these application methods offers distinct advantages, and the choice of which to use depends on the specific requirements of the project, including the size of the area to be covered, the desired thickness of the coating, and the environmental conditions in which the coating will be applied. The versatility of these application methods ensures that there is a suitable solution for every project, whether it involves a small residential repair or a large-scale industrial installation. As the demand for effective moisture management solutions continues to grow, the Global Heavy Duty Vapour Barrier Coating Market is expected to expand, offering new and innovative products that meet the evolving needs of the construction industry.

Residential, Commercial in the Global Heavy Duty Vapour Barrier Coating Market:

The usage of Global Heavy Duty Vapour Barrier Coating Market products in residential and commercial areas highlights their versatility and importance in modern construction. In residential settings, these coatings are primarily used to protect homes from moisture-related issues that can lead to structural damage and health concerns. Basements, for example, are particularly susceptible to moisture infiltration, which can cause mold growth and compromise the integrity of the foundation. By applying a heavy duty vapour barrier coating, homeowners can prevent moisture from penetrating the walls and floors, ensuring a dry and healthy living environment. Additionally, these coatings are used in roofing applications to prevent water vapor from entering the attic space, which can lead to energy inefficiency and damage to insulation materials. In commercial settings, the need for effective moisture management is even more pronounced, as buildings are often larger and subject to more stringent regulatory requirements. Heavy duty vapour barrier coatings are used in a variety of commercial applications, from office buildings to shopping centers, to protect against moisture-related damage and ensure the longevity of the structure. These coatings are particularly important in areas with high humidity or frequent rainfall, where the risk of moisture infiltration is greater. In industrial facilities, where machinery and equipment are often exposed to harsh environmental conditions, vapour barrier coatings provide an essential layer of protection that helps to prevent corrosion and extend the lifespan of valuable assets. The use of these coatings in both residential and commercial settings underscores their critical role in modern construction practices, where the emphasis is on creating durable, energy-efficient, and sustainable buildings. As awareness of the importance of moisture management continues to grow, the demand for heavy duty vapour barrier coatings is expected to increase, driving innovation and expansion in the market.

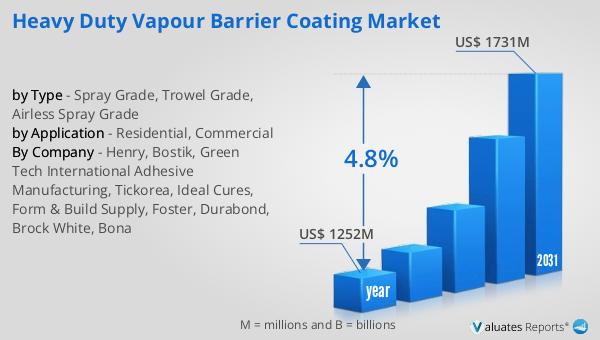

Global Heavy Duty Vapour Barrier Coating Market Outlook:

The outlook for the Global Heavy Duty Vapour Barrier Coating Market indicates a promising future, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately US$ 1252 million, reflecting the strong demand for these essential construction materials. By 2031, the market is projected to reach a revised size of US$ 1731 million, representing a compound annual growth rate (CAGR) of 4.8% during the forecast period. This growth is driven by several factors, including the increasing emphasis on sustainable building practices and the need for effective moisture management solutions in both residential and commercial construction. As the construction industry continues to evolve, the demand for high-performance vapour barrier coatings is expected to rise, supported by advancements in coating technologies and a growing awareness of the importance of moisture control. The market's expansion is also influenced by the increasing prevalence of extreme weather events and the need for buildings that can withstand harsh environmental conditions. As a result, the Global Heavy Duty Vapour Barrier Coating Market is poised for continued growth, offering new opportunities for manufacturers and suppliers to develop innovative products that meet the evolving needs of the construction industry.

| Report Metric | Details |

| Report Name | Heavy Duty Vapour Barrier Coating Market |

| Accounted market size in year | US$ 1252 million |

| Forecasted market size in 2031 | US$ 1731 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Henry, Bostik, Green Tech International Adhesive Manufacturing, Tickorea, Ideal Cures, Form & Build Supply, Foster, Durabond, Brock White, Bona |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |