What is Global Flame Retardant Acrylic Fiber Market?

The Global Flame Retardant Acrylic Fiber Market is a specialized segment within the broader textile industry, focusing on the production and distribution of acrylic fibers that are treated or inherently designed to resist ignition and slow the spread of fire. These fibers are crucial in applications where fire safety is paramount, such as in protective clothing, home textiles, and various industrial uses. The market is driven by increasing safety regulations and the growing awareness of fire hazards in both residential and commercial settings. Flame retardant acrylic fibers are engineered to meet stringent safety standards, making them a preferred choice in industries that prioritize fire resistance. The market is characterized by continuous innovation, with manufacturers investing in research and development to enhance the performance and durability of these fibers. As safety standards evolve and the demand for fire-resistant materials increases, the Global Flame Retardant Acrylic Fiber Market is expected to grow, offering new opportunities for manufacturers and suppliers. This market is not only about meeting current safety needs but also about anticipating future demands and developing solutions that can adapt to changing regulations and consumer expectations.

Inherent Flame Resistant Acrylic Fiber, Treatment Flame Resistant Acrylic Fiber in the Global Flame Retardant Acrylic Fiber Market:

Inherent Flame Resistant Acrylic Fiber and Treatment Flame Resistant Acrylic Fiber are two primary categories within the Global Flame Retardant Acrylic Fiber Market, each with distinct characteristics and applications. Inherent flame-resistant acrylic fibers are designed at the molecular level to resist ignition and combustion. These fibers are manufactured using specific polymers that inherently possess flame-retardant properties, meaning that the fire resistance is built into the fiber itself and does not wash out or diminish over time. This makes them highly durable and suitable for applications where long-term fire resistance is critical. Inherent flame-resistant fibers are often used in environments where exposure to fire or high temperatures is a constant risk, such as in firefighting gear, military uniforms, and industrial safety clothing. On the other hand, treatment flame-resistant acrylic fibers are regular acrylic fibers that have undergone a chemical treatment process to enhance their fire resistance. This treatment involves applying flame-retardant chemicals to the surface of the fibers, which can effectively slow down or prevent the spread of fire. While these fibers may not offer the same level of durability as inherent flame-resistant fibers, they are often more cost-effective and can be used in applications where the risk of fire is lower or where the fibers are not subjected to frequent washing or harsh conditions. Treatment flame-resistant fibers are commonly used in home textiles, such as curtains and upholstery, where they provide an added layer of safety without significantly increasing costs. Both types of flame-resistant acrylic fibers play a crucial role in enhancing safety across various industries. The choice between inherent and treatment flame-resistant fibers often depends on the specific requirements of the application, including factors such as cost, durability, and the level of fire risk. As the demand for fire-resistant materials continues to grow, manufacturers are exploring new technologies and methods to improve the performance and cost-effectiveness of both inherent and treatment flame-resistant acrylic fibers. This ongoing innovation is essential to meet the evolving needs of industries that rely on these materials to protect people and property from the dangers of fire.

Fireproof Clothing, Home Textiles, Automobile, Aerospace, Other in the Global Flame Retardant Acrylic Fiber Market:

The Global Flame Retardant Acrylic Fiber Market finds extensive usage across various sectors, each with unique requirements and safety standards. In the realm of fireproof clothing, flame retardant acrylic fibers are essential for manufacturing garments that provide protection against fire hazards. These fibers are used in the production of firefighting suits, military uniforms, and industrial safety clothing, where their ability to resist ignition and slow the spread of fire can be life-saving. The durability and inherent fire-resistant properties of these fibers make them ideal for environments where exposure to flames or high temperatures is a constant risk. In home textiles, flame retardant acrylic fibers are used to enhance the safety of everyday items such as curtains, upholstery, and bedding. These fibers help prevent the rapid spread of fire in residential settings, providing an added layer of protection for homes and families. The use of flame retardant materials in home textiles is becoming increasingly important as safety regulations become more stringent and consumers become more aware of fire hazards. In the automobile industry, flame retardant acrylic fibers are used in the production of interior components such as seat covers, carpets, and headliners. These fibers help improve the fire safety of vehicles, reducing the risk of fire-related accidents and enhancing passenger safety. The aerospace industry also relies on flame retardant acrylic fibers for the production of interior components in aircraft. These fibers are used in seat covers, carpets, and other materials that must meet strict fire safety standards to ensure the safety of passengers and crew. The ability of flame retardant acrylic fibers to resist ignition and slow the spread of fire is crucial in the confined spaces of an aircraft, where fire safety is of utmost importance. Beyond these specific applications, flame retardant acrylic fibers are used in a variety of other industries where fire safety is a concern. This includes the production of protective gear for workers in high-risk environments, as well as in the construction of buildings and infrastructure where fire-resistant materials are required to meet safety codes and regulations. The versatility and effectiveness of flame retardant acrylic fibers make them a valuable resource in enhancing safety across a wide range of applications. As the demand for fire-resistant materials continues to grow, the Global Flame Retardant Acrylic Fiber Market is poised to expand, offering new opportunities for innovation and development in the field of fire safety.

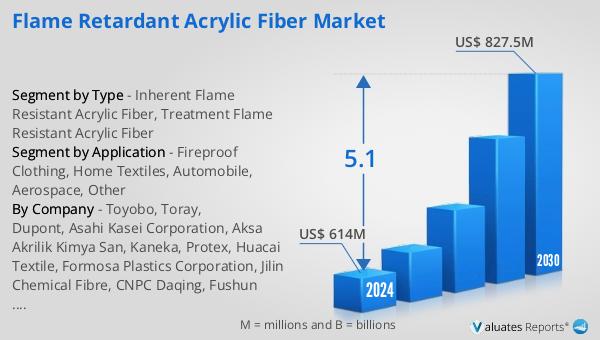

Global Flame Retardant Acrylic Fiber Market Outlook:

In 2024, the global market for Flame Retardant Acrylic Fiber was valued at approximately $642 million. This market is anticipated to experience significant growth over the coming years, with projections indicating that it will reach a revised size of around $905 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.1% during the forecast period. The increasing demand for flame retardant materials across various industries, driven by heightened safety regulations and growing awareness of fire hazards, is a key factor contributing to this market expansion. As industries such as textiles, automotive, aerospace, and construction continue to prioritize fire safety, the demand for flame retardant acrylic fibers is expected to rise. Manufacturers are investing in research and development to enhance the performance and cost-effectiveness of these fibers, further driving market growth. The market's expansion is also supported by technological advancements and innovations in flame retardant materials, which are enabling the development of new applications and solutions to meet evolving safety standards. As the Global Flame Retardant Acrylic Fiber Market continues to grow, it presents significant opportunities for manufacturers, suppliers, and stakeholders to capitalize on the increasing demand for fire-resistant materials and contribute to enhancing safety across various industries.

| Report Metric | Details |

| Report Name | Flame Retardant Acrylic Fiber Market |

| Accounted market size in year | US$ 642 million |

| Forecasted market size in 2031 | US$ 905 million |

| CAGR | 5.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Toyobo, Toray, Dupont, Asahi Kasei Corporation, Aksa Akrilik Kimya San, Kaneka, Protex, Huacai Textile, Formosa Plastics Corporation, Jilin Chemical Fibre, CNPC Daqing, Fushun Rayva Fiber |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |