What is Global Backwash Valve Market?

The Global Backwash Valve Market is a crucial segment within the broader water treatment industry. Backwash valves are essential components used in various filtration systems to clean and maintain the efficiency of filters by reversing the flow of water. This process helps in removing accumulated debris and contaminants, ensuring that the filtration system operates optimally. These valves are widely used in residential, commercial, and industrial applications, where maintaining clean water is of utmost importance. The market for backwash valves is driven by the increasing demand for clean water, stringent environmental regulations, and the need for efficient water management systems. Technological advancements have led to the development of more efficient and durable backwash valves, further propelling market growth. The market is characterized by a diverse range of products, including automatic and manual backwash valves, catering to different user needs and preferences. As water scarcity becomes a growing concern globally, the importance of efficient water filtration systems, and consequently backwash valves, is expected to rise. This market is poised for growth as industries and municipalities continue to invest in advanced water treatment solutions to meet the increasing demand for clean and safe water.

Automatic Valve, Manual Valve in the Global Backwash Valve Market:

In the Global Backwash Valve Market, two primary types of valves are prevalent: automatic and manual. Automatic backwash valves are designed to operate without human intervention, making them highly efficient and convenient for users. These valves are equipped with sensors and timers that trigger the backwashing process at predetermined intervals or when the system detects a certain level of contamination. This automation ensures that the filtration system remains clean and functional without requiring constant monitoring. Automatic valves are particularly beneficial in large-scale industrial and municipal water treatment facilities where manual operation would be impractical due to the scale of operations. They help in reducing labor costs and minimizing human error, thereby enhancing the overall efficiency of the water treatment process. On the other hand, manual backwash valves require human intervention to initiate the backwashing process. These valves are typically more cost-effective than their automatic counterparts and are often used in smaller systems where the scale of operation does not justify the investment in automation. Manual valves offer users greater control over the backwashing process, allowing them to adjust the timing and frequency based on specific needs and conditions. This flexibility can be advantageous in certain applications where water quality and contamination levels vary significantly. Despite their differences, both automatic and manual backwash valves play a vital role in maintaining the efficiency and longevity of filtration systems. The choice between the two often depends on factors such as budget, scale of operation, and specific user requirements. As the demand for clean water continues to rise, the market for both types of backwash valves is expected to grow, driven by the need for efficient and reliable water treatment solutions. Manufacturers are continually innovating to improve the performance and durability of these valves, ensuring they meet the evolving needs of the market. Whether automatic or manual, backwash valves are indispensable components in the quest for clean and safe water, underscoring their importance in the global water treatment landscape.

Municipal Water Treatment, Industrial, Agriculture, Others in the Global Backwash Valve Market:

The Global Backwash Valve Market finds extensive usage across various sectors, including municipal water treatment, industrial applications, agriculture, and others. In municipal water treatment, backwash valves are integral to maintaining the efficiency of large-scale filtration systems that supply clean water to urban populations. These valves help in removing accumulated debris and contaminants from filters, ensuring a continuous supply of safe drinking water. The automation of backwash valves in municipal systems enhances operational efficiency, reduces labor costs, and minimizes the risk of human error. In industrial applications, backwash valves are used in processes where water is a critical component, such as in cooling systems, chemical processing, and food and beverage production. These valves help in maintaining the purity of water used in these processes, preventing contamination and ensuring product quality. The ability to automate the backwashing process in industrial settings is particularly beneficial, as it allows for continuous operation without the need for manual intervention. In agriculture, backwash valves are used in irrigation systems to ensure that the water supplied to crops is free from contaminants that could harm plant health. These valves help in maintaining the efficiency of irrigation systems, reducing water wastage, and ensuring optimal crop yield. The use of backwash valves in agriculture is becoming increasingly important as water scarcity and the need for sustainable farming practices gain prominence. Beyond these primary sectors, backwash valves are also used in various other applications, such as in swimming pools, aquariums, and residential water filtration systems. In these settings, backwash valves help in maintaining water quality and ensuring the longevity of filtration systems. The versatility and efficiency of backwash valves make them indispensable components in a wide range of water treatment applications, highlighting their importance in the global market. As the demand for clean and safe water continues to grow, the usage of backwash valves across these sectors is expected to increase, driving market growth and innovation.

Global Backwash Valve Market Outlook:

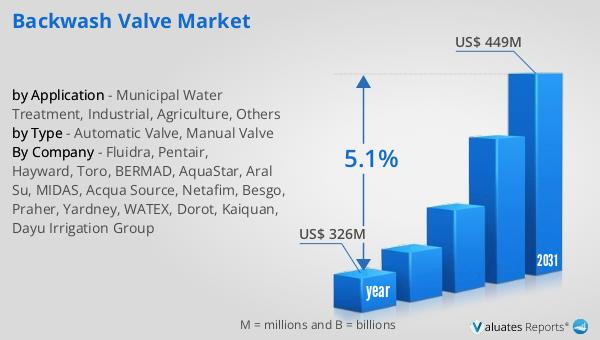

The global market for backwash valves was valued at $326 million in 2024 and is anticipated to expand to a revised size of $449 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.1% over the forecast period. This growth trajectory underscores the increasing demand for efficient water treatment solutions across various sectors. The rising awareness about the importance of clean water, coupled with stringent environmental regulations, is driving the adoption of advanced backwash valves. These valves play a crucial role in maintaining the efficiency and longevity of filtration systems, making them indispensable in the quest for clean and safe water. The market's growth is further fueled by technological advancements that have led to the development of more efficient and durable backwash valves. As industries and municipalities continue to invest in advanced water treatment solutions, the demand for backwash valves is expected to rise. This market outlook highlights the significant opportunities for growth and innovation in the backwash valve market, as stakeholders seek to address the challenges of water scarcity and contamination. The projected growth of the market reflects the increasing importance of efficient water management systems in ensuring a sustainable future.

| Report Metric | Details |

| Report Name | Backwash Valve Market |

| Accounted market size in year | US$ 326 million |

| Forecasted market size in 2031 | US$ 449 million |

| CAGR | 5.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fluidra, Pentair, Hayward, Toro, BERMAD, AquaStar, Aral Su, MIDAS, Acqua Source, Netafim, Besgo, Praher, Yardney, WATEX, Dorot, Kaiquan, Dayu Irrigation Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |