What is Global CoPolyester Hot Melt Adhesives Market?

The Global CoPolyester Hot Melt Adhesives Market refers to the worldwide industry focused on the production and distribution of adhesives made from copolyester materials. These adhesives are known for their versatility and strong bonding capabilities, making them suitable for a wide range of applications. Unlike traditional adhesives, copolyester hot melt adhesives are applied in a molten state and solidify upon cooling, creating a durable bond. This market is driven by the increasing demand for efficient and environmentally friendly adhesive solutions across various industries. The growth of sectors such as packaging, textiles, and automotive has significantly contributed to the expansion of this market. Additionally, the shift towards sustainable and non-toxic adhesive options has further propelled the demand for copolyester hot melt adhesives. As industries continue to seek innovative bonding solutions, the Global CoPolyester Hot Melt Adhesives Market is expected to witness substantial growth, driven by technological advancements and the rising need for high-performance adhesives.

Granulat, Power in the Global CoPolyester Hot Melt Adhesives Market:

Granulat and powder forms of copolyester hot melt adhesives play a crucial role in the Global CoPolyester Hot Melt Adhesives Market. Granulat, or granular form, is a popular choice due to its ease of handling and precise application. These granules are typically used in automated systems where consistent and controlled adhesive application is required. The granules melt quickly and evenly, providing a reliable bond for various substrates. This form is particularly favored in industries where speed and efficiency are paramount, such as packaging and textiles. On the other hand, powder-based copolyester hot melt adhesives offer unique advantages in specific applications. The powder form allows for a more flexible application, as it can be easily mixed with other materials or applied in varying thicknesses. This versatility makes it suitable for complex bonding requirements, such as in the automotive industry where different materials need to be bonded together seamlessly. The powder form also allows for precise control over the adhesive's properties, enabling manufacturers to tailor the adhesive to specific needs. Both granulat and powder forms are integral to the market, catering to diverse industrial needs and ensuring that manufacturers have the right adhesive solution for their specific applications. The choice between granulat and powder forms often depends on the specific requirements of the application, including the type of substrates involved, the desired bond strength, and the environmental conditions. For instance, in the packaging industry, where speed and efficiency are crucial, granulat forms are often preferred due to their quick melting and application properties. In contrast, the automotive industry, which often deals with complex bonding requirements, may opt for powder forms to achieve the desired flexibility and strength. The versatility of these forms also extends to their environmental impact. As industries increasingly prioritize sustainability, both granulat and powder forms of copolyester hot melt adhesives offer eco-friendly solutions. They are typically free from solvents and other harmful chemicals, making them a safer choice for both manufacturers and end-users. This aligns with the growing trend towards sustainable manufacturing practices and the demand for non-toxic adhesive solutions. Furthermore, the development of advanced formulations in both granulat and powder forms continues to drive innovation in the market. Manufacturers are constantly exploring new ways to enhance the performance of these adhesives, whether through improved bonding strength, faster application times, or greater resistance to environmental factors. This ongoing innovation ensures that the Global CoPolyester Hot Melt Adhesives Market remains dynamic and responsive to the evolving needs of various industries. In conclusion, the granulat and powder forms of copolyester hot melt adhesives are vital components of the market, offering tailored solutions for a wide range of applications. Their versatility, efficiency, and environmental benefits make them indispensable in industries such as packaging, textiles, and automotive, where reliable and high-performance adhesive solutions are essential.

Packing, Textile, Automotive, Others in the Global CoPolyester Hot Melt Adhesives Market:

The Global CoPolyester Hot Melt Adhesives Market finds extensive usage across various sectors, including packaging, textiles, automotive, and others, due to its versatile bonding capabilities and environmentally friendly properties. In the packaging industry, copolyester hot melt adhesives are widely used for sealing cartons, boxes, and other packaging materials. Their quick-setting nature and strong adhesion make them ideal for high-speed packaging lines, ensuring that products are securely sealed and protected during transit. Additionally, these adhesives are often used in the production of labels and tapes, providing a reliable bond that withstands various environmental conditions. In the textile industry, copolyester hot melt adhesives are employed for bonding fabrics and other materials. They offer a flexible and durable bond that can withstand repeated washing and wear, making them suitable for applications such as garment manufacturing and textile laminations. The automotive industry also benefits significantly from the use of copolyester hot melt adhesives. These adhesives are used for bonding various components, including interior trims, upholstery, and electronic assemblies. Their ability to bond different materials, such as plastics, metals, and fabrics, makes them indispensable in automotive manufacturing, where diverse materials are often used. Moreover, the adhesives' resistance to heat and chemicals ensures that they maintain their integrity in the demanding conditions of automotive environments. Beyond these primary sectors, copolyester hot melt adhesives are also used in other industries, such as electronics, woodworking, and construction. In electronics, they provide reliable bonding for components and assemblies, ensuring that devices remain intact and functional. In woodworking, these adhesives are used for edge banding and veneering, offering a strong bond that enhances the durability and appearance of wooden products. In construction, copolyester hot melt adhesives are used for insulation and panel bonding, contributing to the structural integrity and energy efficiency of buildings. The versatility of copolyester hot melt adhesives extends to their application methods as well. They can be applied using various techniques, including spray, roll, and extrusion, allowing manufacturers to choose the most suitable method for their specific needs. This adaptability ensures that the adhesives can be used in a wide range of applications, from small-scale projects to large industrial operations. Furthermore, the environmental benefits of copolyester hot melt adhesives make them an attractive choice for industries seeking sustainable solutions. These adhesives are typically free from solvents and other harmful chemicals, reducing their impact on the environment and improving workplace safety. This aligns with the growing trend towards eco-friendly manufacturing practices and the increasing demand for non-toxic adhesive solutions. In summary, the Global CoPolyester Hot Melt Adhesives Market plays a crucial role in various industries, offering versatile and environmentally friendly bonding solutions. From packaging and textiles to automotive and beyond, these adhesives provide reliable performance and adaptability, meeting the diverse needs of manufacturers and contributing to the advancement of sustainable practices across sectors.

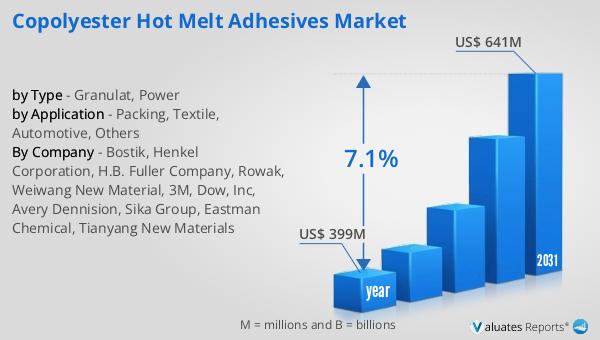

Global CoPolyester Hot Melt Adhesives Market Outlook:

The outlook for the Global CoPolyester Hot Melt Adhesives Market indicates a promising growth trajectory. In 2024, the market was valued at approximately $399 million, reflecting its significant presence in the adhesive industry. Looking ahead, the market is expected to expand substantially, reaching an estimated value of $641 million by 2031. This growth is projected to occur at a compound annual growth rate (CAGR) of 7.1% over the forecast period. This upward trend underscores the increasing demand for copolyester hot melt adhesives across various industries, driven by their versatile applications and environmentally friendly properties. The market's expansion is likely fueled by the continuous advancements in adhesive technology, which enhance the performance and efficiency of these products. Additionally, the growing emphasis on sustainable and non-toxic adhesive solutions aligns with the market's trajectory, as industries seek to reduce their environmental impact and improve safety standards. As a result, the Global CoPolyester Hot Melt Adhesives Market is poised for significant growth, offering numerous opportunities for manufacturers and stakeholders to capitalize on the rising demand for high-performance adhesive solutions.

| Report Metric | Details |

| Report Name | CoPolyester Hot Melt Adhesives Market |

| Accounted market size in year | US$ 399 million |

| Forecasted market size in 2031 | US$ 641 million |

| CAGR | 7.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Bostik, Henkel Corporation, H.B. Fuller Company, Rowak, Weiwang New Material, 3M, Dow, Inc, Avery Dennision, Sika Group, Eastman Chemical, Tianyang New Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |