What is Global Ceramic Membrane Element Market?

The Global Ceramic Membrane Element Market is a specialized segment within the broader filtration industry, focusing on the use of ceramic materials to create membrane elements. These elements are integral to various filtration processes, offering a robust and efficient solution for separating particles from liquids or gases. Ceramic membranes are known for their durability, high thermal stability, and resistance to chemical corrosion, making them suitable for demanding applications across multiple industries. The market for these elements is driven by the increasing demand for efficient and sustainable filtration solutions, particularly in sectors such as water treatment, food and beverage processing, and chemical manufacturing. As industries continue to seek environmentally friendly and cost-effective filtration methods, the adoption of ceramic membrane elements is expected to grow. These elements are particularly valued for their long lifespan and ability to operate under extreme conditions, which reduces the need for frequent replacements and maintenance. The market is characterized by ongoing research and development efforts aimed at enhancing the performance and cost-effectiveness of ceramic membranes, thereby expanding their applicability and appeal across various sectors.

Hyperfiltration, Microfiltration, Nanofiltration in the Global Ceramic Membrane Element Market:

Hyperfiltration, microfiltration, and nanofiltration are three key processes within the Global Ceramic Membrane Element Market, each serving distinct purposes and applications. Hyperfiltration, also known as reverse osmosis, is a process that removes the smallest particles, including ions and molecules, from a solution. This method is widely used in desalination and water purification, where the goal is to produce clean, potable water from seawater or brackish sources. Ceramic membranes used in hyperfiltration are prized for their ability to withstand high pressures and harsh chemical environments, ensuring long-term reliability and efficiency. Microfiltration, on the other hand, targets larger particles such as bacteria, suspended solids, and some viruses. This process is commonly employed in the food and beverage industry, where it helps in clarifying liquids, removing impurities, and ensuring product safety. Ceramic membranes in microfiltration offer advantages such as high permeability, mechanical strength, and ease of cleaning, making them ideal for applications requiring frequent sterilization and maintenance. Nanofiltration sits between hyperfiltration and microfiltration, focusing on the removal of multivalent ions and small organic molecules. This process is often used in water softening, dye removal, and the treatment of industrial effluents. Ceramic membranes in nanofiltration provide a balance between selectivity and permeability, allowing for efficient separation processes while maintaining high flow rates. The versatility and robustness of ceramic membranes across these filtration processes make them a valuable asset in industries seeking to optimize their filtration systems. As the demand for clean water and efficient filtration solutions continues to rise, the role of ceramic membranes in hyperfiltration, microfiltration, and nanofiltration is expected to become increasingly significant.

Biomedicine, Sewage Treatment, Food and Beverage, Chemical Industry, Other in the Global Ceramic Membrane Element Market:

The Global Ceramic Membrane Element Market finds extensive usage across various sectors, including biomedicine, sewage treatment, food and beverage, chemical industry, and others. In biomedicine, ceramic membranes are utilized for their superior filtration capabilities, which are crucial in processes such as blood purification, drug development, and the production of high-purity water for laboratory use. Their chemical resistance and ability to withstand sterilization processes make them ideal for maintaining the stringent hygiene standards required in medical applications. In sewage treatment, ceramic membranes play a vital role in the removal of contaminants and pathogens from wastewater, contributing to the production of clean, reusable water. Their durability and resistance to fouling ensure consistent performance and reduced maintenance costs, making them a cost-effective solution for large-scale water treatment facilities. In the food and beverage industry, ceramic membranes are employed to enhance product quality and safety by removing impurities, bacteria, and other unwanted particles from liquids. They are used in processes such as milk clarification, juice filtration, and beer stabilization, where maintaining the integrity and taste of the product is paramount. The chemical industry benefits from ceramic membranes in applications such as solvent recovery, catalyst separation, and the purification of chemical compounds. Their ability to operate under extreme conditions and resist chemical attack makes them suitable for handling aggressive substances and high-temperature processes. Beyond these sectors, ceramic membranes are also used in areas such as electronics manufacturing, mining, and environmental protection, where their unique properties offer advantages in terms of efficiency, reliability, and sustainability. As industries continue to prioritize environmental responsibility and operational efficiency, the adoption of ceramic membrane elements is likely to expand, driven by their ability to deliver high-performance filtration solutions across a wide range of applications.

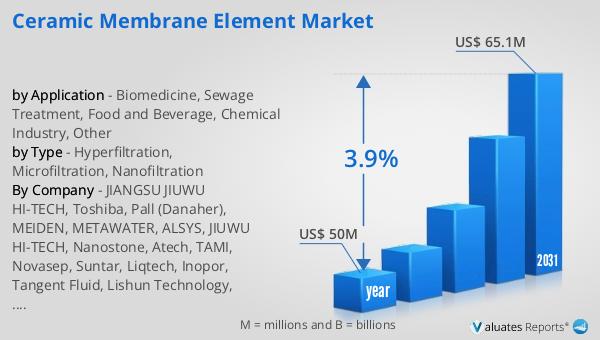

Global Ceramic Membrane Element Market Outlook:

The global market for ceramic membrane elements was valued at $50 million in 2024 and is anticipated to grow to a revised size of $65.1 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.9% over the forecast period. This growth trajectory underscores the increasing demand for ceramic membrane elements across various industries, driven by their superior performance characteristics and the growing need for efficient filtration solutions. The market's expansion is supported by advancements in ceramic membrane technology, which continue to enhance their applicability and cost-effectiveness. As industries face mounting pressure to adopt sustainable practices and improve operational efficiencies, ceramic membranes offer a compelling solution due to their durability, chemical resistance, and ability to operate under extreme conditions. The projected growth in the market size indicates a positive outlook for the adoption of ceramic membrane elements, as they become an integral component of modern filtration systems. This trend is expected to be further bolstered by ongoing research and development efforts aimed at optimizing the performance and reducing the costs of ceramic membranes, thereby broadening their appeal and accessibility to a wider range of applications.

| Report Metric | Details |

| Report Name | Ceramic Membrane Element Market |

| Accounted market size in year | US$ 50 million |

| Forecasted market size in 2031 | US$ 65.1 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | JIANGSU JIUWU HI-TECH, Toshiba, Pall (Danaher), MEIDEN, METAWATER, ALSYS, JIUWU HI-TECH, Nanostone, Atech, TAMI, Novasep, Suntar, Liqtech, Inopor, Tangent Fluid, Lishun Technology, Dongqiang |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |