What is Global Mold Cavity Pressure Sensors Market?

The Global Mold Cavity Pressure Sensors Market is a specialized segment within the broader sensor industry, focusing on devices that measure the pressure within mold cavities during the manufacturing process. These sensors are crucial for ensuring the quality and consistency of products made through injection molding, a common manufacturing technique used in various industries. By providing real-time data on the pressure inside the mold, these sensors help manufacturers optimize the molding process, reduce defects, and improve product quality. The market for these sensors is driven by the increasing demand for high-quality, precision-engineered products across industries such as automotive, electronics, and medical devices. As manufacturers strive to enhance efficiency and product quality, the adoption of mold cavity pressure sensors is expected to grow, supported by advancements in sensor technology and the increasing integration of smart manufacturing practices. The market is characterized by a mix of established players and emerging companies, all competing to offer innovative solutions that meet the evolving needs of manufacturers worldwide. With the ongoing trend towards automation and smart manufacturing, the Global Mold Cavity Pressure Sensors Market is poised for significant growth in the coming years.

Direct Cavity Pressure Sensors, Indirect Cavity Pressure Sensors in the Global Mold Cavity Pressure Sensors Market:

Direct Cavity Pressure Sensors and Indirect Cavity Pressure Sensors are two primary types of sensors used in the Global Mold Cavity Pressure Sensors Market, each with distinct characteristics and applications. Direct Cavity Pressure Sensors are installed directly into the mold cavity, allowing them to measure the pressure exerted on the mold surface with high accuracy. These sensors are typically used in applications where precise pressure measurement is critical, such as in the production of high-precision components for the automotive and medical industries. The direct contact with the mold cavity enables these sensors to provide real-time data, which is essential for monitoring and controlling the injection molding process. This real-time feedback helps manufacturers optimize the molding process, reduce cycle times, and minimize defects, ultimately leading to improved product quality and reduced production costs. On the other hand, Indirect Cavity Pressure Sensors are installed outside the mold cavity and measure the pressure indirectly through the mold structure. These sensors are often used in applications where direct installation is not feasible or where the mold design does not allow for direct sensor placement. Indirect sensors are typically less expensive than direct sensors and are easier to install and maintain, making them a popular choice for many manufacturers. However, they may not provide the same level of accuracy as direct sensors, as the pressure measurement is influenced by the mold structure and material properties. Despite this limitation, indirect sensors are widely used in various industries due to their cost-effectiveness and ease of use. Both types of sensors play a crucial role in the injection molding process, providing manufacturers with the data needed to ensure product quality and process efficiency. As the demand for high-quality, precision-engineered products continues to grow, the adoption of both direct and indirect cavity pressure sensors is expected to increase, driven by advancements in sensor technology and the increasing integration of smart manufacturing practices. The choice between direct and indirect sensors depends on various factors, including the specific application requirements, mold design, and budget constraints. Manufacturers must carefully evaluate these factors to select the most suitable sensor type for their needs, ensuring optimal performance and product quality.

Automotive, Medical, Electronics, Home Appliances, Chemicals, Others in the Global Mold Cavity Pressure Sensors Market:

The Global Mold Cavity Pressure Sensors Market finds extensive usage across various industries, including automotive, medical, electronics, home appliances, chemicals, and others, each benefiting from the precision and efficiency these sensors bring to the manufacturing process. In the automotive industry, mold cavity pressure sensors are crucial for producing high-quality components such as dashboards, bumpers, and interior trims. These sensors help ensure that each part meets the stringent quality standards required for automotive applications, reducing the risk of defects and improving overall vehicle safety and performance. In the medical industry, the demand for precision and reliability is even higher, as mold cavity pressure sensors are used in the production of critical components such as syringes, vials, and medical devices. The real-time data provided by these sensors allows manufacturers to maintain tight control over the molding process, ensuring that each component meets the necessary quality and safety standards. In the electronics industry, mold cavity pressure sensors are used to produce components such as connectors, housings, and circuit boards, where precision and consistency are essential for ensuring product performance and reliability. The home appliances industry also benefits from these sensors, as they are used in the production of components such as washing machine drums, refrigerator liners, and vacuum cleaner parts. By optimizing the molding process, these sensors help manufacturers produce high-quality, durable components that meet consumer expectations. In the chemicals industry, mold cavity pressure sensors are used in the production of various plastic products, helping manufacturers maintain consistent quality and reduce waste. Other industries, such as consumer goods and packaging, also rely on these sensors to ensure the quality and consistency of their products. As the demand for high-quality, precision-engineered products continues to grow across these industries, the adoption of mold cavity pressure sensors is expected to increase, driven by advancements in sensor technology and the increasing integration of smart manufacturing practices.

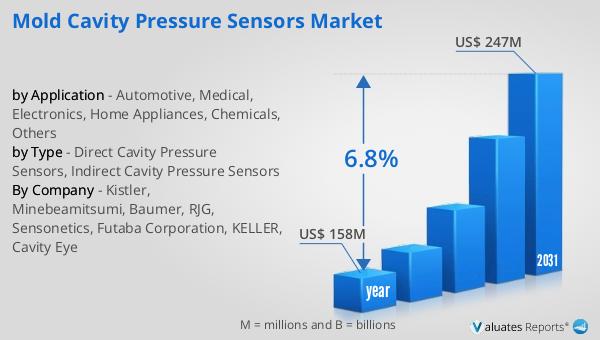

Global Mold Cavity Pressure Sensors Market Outlook:

The global market for Mold Cavity Pressure Sensors was valued at $158 million in 2024 and is anticipated to expand to a revised size of $247 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.8% during the forecast period. This growth trajectory underscores the increasing importance of these sensors in various manufacturing sectors. As industries continue to evolve and demand higher precision and efficiency, the role of mold cavity pressure sensors becomes even more critical. These sensors not only help in maintaining product quality but also contribute to reducing production costs by minimizing defects and optimizing the manufacturing process. The projected growth in the market size indicates a robust demand for these sensors, driven by advancements in technology and the growing trend towards automation and smart manufacturing. As manufacturers strive to enhance their production capabilities and meet the ever-increasing quality standards, the adoption of mold cavity pressure sensors is expected to rise significantly. This growth is further supported by the increasing awareness of the benefits these sensors offer, such as improved product quality, reduced cycle times, and enhanced process efficiency. As a result, the Global Mold Cavity Pressure Sensors Market is poised for substantial growth in the coming years, offering significant opportunities for both established players and new entrants in the market.

| Report Metric | Details |

| Report Name | Mold Cavity Pressure Sensors Market |

| Accounted market size in year | US$ 158 million |

| Forecasted market size in 2031 | US$ 247 million |

| CAGR | 6.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kistler, Minebeamitsumi, Baumer, RJG, Sensonetics, Futaba Corporation, KELLER, Cavity Eye |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |