What is Global Automotive Thermoplastic Vulcanizate (TPV) Market?

The Global Automotive Thermoplastic Vulcanizate (TPV) Market is a dynamic and rapidly evolving sector within the automotive industry. TPV is a type of thermoplastic elastomer that combines the properties of rubber with the processing advantages of plastics. This unique combination makes TPV an ideal material for various automotive applications, offering benefits such as flexibility, durability, and resistance to heat and chemicals. The market for automotive TPV is driven by the increasing demand for lightweight and fuel-efficient vehicles, as TPV materials contribute to weight reduction without compromising performance. Additionally, the growing emphasis on sustainability and environmental regulations has led to a shift towards materials that are recyclable and have a lower environmental impact, further boosting the demand for TPV in the automotive sector. As automakers continue to innovate and develop new vehicle models, the need for advanced materials like TPV is expected to grow, making it a crucial component in the future of automotive manufacturing.

PP/EPDM TPV, Phenolic Resin Cured TPV, Sulfur Cured TPV, Peroxide Cured TPV in the Global Automotive Thermoplastic Vulcanizate (TPV) Market:

PP/EPDM TPV, Phenolic Resin Cured TPV, Sulfur Cured TPV, and Peroxide Cured TPV are different types of thermoplastic vulcanizates used in the automotive industry, each offering distinct properties and advantages. PP/EPDM TPV is a blend of polypropylene (PP) and ethylene propylene diene monomer (EPDM) rubber, known for its excellent weather resistance, flexibility, and impact strength. This type of TPV is commonly used in automotive seals, gaskets, and weatherstripping, where durability and resistance to environmental factors are crucial. Phenolic Resin Cured TPV involves the use of phenolic resins as curing agents, resulting in a material with enhanced thermal stability and chemical resistance. This makes it suitable for under-the-hood applications, such as hoses and engine covers, where exposure to high temperatures and harsh chemicals is common. Sulfur Cured TPV utilizes sulfur as a curing agent, providing a balance of elasticity and strength. This type of TPV is often used in applications requiring high tensile strength and abrasion resistance, such as suspension bushings and vibration dampers. Peroxide Cured TPV, on the other hand, uses peroxide as a curing agent, offering superior heat resistance and aging properties. This makes it ideal for applications in high-temperature environments, such as turbocharger hoses and exhaust system components. Each type of TPV brings unique benefits to the automotive industry, allowing manufacturers to select the most appropriate material for specific applications based on performance requirements and environmental conditions. The versatility and adaptability of these TPV types contribute to their widespread use in the automotive sector, supporting the industry's ongoing efforts to enhance vehicle performance, safety, and sustainability.

Internal Combustion Engine Vehicle, Electric Vehicle in the Global Automotive Thermoplastic Vulcanizate (TPV) Market:

The usage of Global Automotive Thermoplastic Vulcanizate (TPV) Market in Internal Combustion Engine Vehicles (ICEVs) and Electric Vehicles (EVs) highlights the material's versatility and adaptability to different automotive technologies. In ICEVs, TPV is extensively used for its ability to withstand high temperatures and harsh chemical environments. Components such as engine covers, hoses, and seals benefit from TPV's thermal stability and chemical resistance, ensuring reliable performance under the hood. Additionally, TPV's lightweight nature contributes to overall vehicle weight reduction, enhancing fuel efficiency and reducing emissions. As automakers strive to meet stringent environmental regulations, the use of TPV in ICEVs supports the industry's efforts to produce cleaner and more efficient vehicles. In the realm of Electric Vehicles, TPV plays a crucial role in addressing the unique challenges posed by electric drivetrains. The material's excellent electrical insulation properties make it suitable for use in battery enclosures, cable insulation, and other electrical components, ensuring safety and reliability. Furthermore, TPV's flexibility and durability are advantageous in the design of EV-specific components, such as charging ports and connectors, which require frequent handling and exposure to varying environmental conditions. As the demand for EVs continues to rise, driven by the global push towards sustainable transportation, the role of TPV in enhancing the performance and safety of electric vehicles becomes increasingly important. The material's ability to meet the diverse requirements of both ICEVs and EVs underscores its significance in the automotive industry, as manufacturers seek innovative solutions to improve vehicle performance, efficiency, and sustainability.

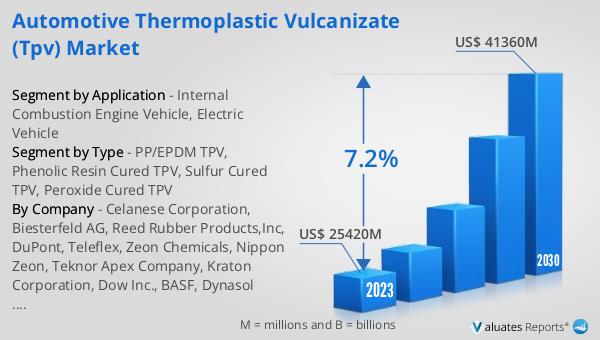

Global Automotive Thermoplastic Vulcanizate (TPV) Market Outlook:

The global market for Automotive Thermoplastic Vulcanizate (TPV) was valued at approximately $29,020 million in 2024. It is anticipated to expand significantly, reaching an estimated size of $46,890 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 7.2% over the forecast period. This upward trend in the TPV market is indicative of the increasing demand for advanced materials that offer a combination of flexibility, durability, and environmental benefits. As the automotive industry continues to evolve, driven by technological advancements and a shift towards more sustainable practices, the role of TPV becomes even more critical. The material's ability to contribute to vehicle weight reduction, enhance fuel efficiency, and meet stringent environmental regulations positions it as a key component in the future of automotive manufacturing. The projected growth of the TPV market underscores the industry's commitment to innovation and sustainability, as manufacturers seek to develop vehicles that are not only high-performing but also environmentally responsible. This market outlook highlights the significant opportunities for growth and development within the TPV sector, as it continues to play a vital role in shaping the future of the automotive industry.

| Report Metric | Details |

| Report Name | Automotive Thermoplastic Vulcanizate (TPV) Market |

| Accounted market size in year | US$ 29020 million |

| Forecasted market size in 2031 | US$ 46890 million |

| CAGR | 7.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Celanese Corporation, Biesterfeld AG, Reed Rubber Products,Inc, DuPont, Teleflex, Zeon Chemicals, Nippon Zeon, Teknor Apex Company, Kraton Corporation, Dow Inc., BASF, Dynasol Group, Avient, PolyOne, Nexeo Plastics, Entec Polymers, Exxonmobil, Mitsubishi, KUMHO POLYCHEM |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |