What is Global Aspart Polyurea Market?

The Global Aspart Polyurea Market is a specialized segment within the broader chemical industry, focusing on the production and application of aspart polyurea coatings. These coatings are known for their exceptional durability, flexibility, and resistance to environmental factors, making them ideal for a variety of applications. Aspart polyurea is a type of elastomer that is formed by the reaction of an isocyanate component with a resin blend component. This unique chemical composition allows it to cure rapidly, even in low temperatures, and provides a robust protective layer that can withstand harsh conditions. The market for aspart polyurea is driven by its increasing use in industries such as construction, automotive, and marine, where it is used to protect surfaces from corrosion, abrasion, and chemical exposure. Additionally, its waterproofing capabilities make it a popular choice for roofing and flooring applications. As industries continue to seek materials that offer longevity and performance, the demand for aspart polyurea is expected to grow, supported by advancements in application technologies and the development of new formulations that enhance its properties.

Anti-corrosion, Water Proof, Other in the Global Aspart Polyurea Market:

In the realm of the Global Aspart Polyurea Market, the applications of anti-corrosion, waterproofing, and other uses are pivotal in understanding the market's dynamics and growth potential. Anti-corrosion applications are particularly significant in industries where metal structures are prevalent, such as in construction, automotive, and marine sectors. Aspart polyurea coatings provide a protective barrier that prevents rust and degradation caused by exposure to moisture, chemicals, and environmental pollutants. This is crucial for extending the lifespan of metal structures and reducing maintenance costs. The rapid curing time and strong adhesion properties of aspart polyurea make it an ideal choice for anti-corrosion applications, as it minimizes downtime and ensures long-lasting protection. In the construction industry, for example, steel beams and other metal components are often coated with aspart polyurea to prevent rust and maintain structural integrity over time. Similarly, in the automotive industry, aspart polyurea is used to coat vehicle underbodies and other metal parts to protect them from road salt and other corrosive elements. The marine industry also benefits from aspart polyurea's anti-corrosion properties, as it is used to coat ship hulls and other metal components exposed to saltwater and harsh marine environments. Waterproofing is another critical application of aspart polyurea, particularly in the construction and infrastructure sectors. The ability of aspart polyurea to form a seamless, impermeable membrane makes it an excellent choice for waterproofing roofs, basements, and other structures that are susceptible to water infiltration. Unlike traditional waterproofing materials, aspart polyurea can be applied quickly and cures rapidly, allowing for faster project completion and reduced labor costs. Its flexibility and ability to adhere to various substrates, including concrete, wood, and metal, make it versatile for different waterproofing needs. In addition to roofs and basements, aspart polyurea is also used for waterproofing bridges, tunnels, and parking decks, where it provides a durable barrier against water and moisture. The construction of water containment structures, such as tanks and reservoirs, also benefits from aspart polyurea's waterproofing capabilities, ensuring that these structures remain leak-free and maintain their integrity over time. Beyond anti-corrosion and waterproofing, aspart polyurea finds applications in a variety of other areas, driven by its unique properties and versatility. One such application is in the realm of flooring, where aspart polyurea is used to create durable, slip-resistant surfaces in industrial and commercial settings. Its resistance to chemicals, abrasion, and impact makes it ideal for use in warehouses, factories, and other high-traffic areas where floors are subject to heavy wear and tear. Aspart polyurea coatings can also be customized with different textures and colors, allowing for aesthetic flexibility in addition to functional benefits. Another emerging application of aspart polyurea is in the field of energy, where it is used to coat wind turbine blades and solar panels. The protective layer provided by aspart polyurea helps to enhance the durability and efficiency of these renewable energy technologies, contributing to their long-term performance and sustainability. Additionally, aspart polyurea is used in the manufacturing of protective gear and equipment, such as helmets and body armor, where its impact resistance and lightweight properties are highly valued. As industries continue to innovate and seek materials that offer superior performance and protection, the range of applications for aspart polyurea is likely to expand, further driving the growth of the Global Aspart Polyurea Market.

Industrial Anticorrosion, Building Waterproof, Other in the Global Aspart Polyurea Market:

The usage of Global Aspart Polyurea Market in industrial anticorrosion, building waterproofing, and other areas highlights its versatility and effectiveness in addressing various industry needs. In industrial anticorrosion applications, aspart polyurea is used to protect metal structures and equipment from the damaging effects of corrosion. This is particularly important in industries such as oil and gas, where pipelines, storage tanks, and other metal components are exposed to harsh chemicals and environmental conditions. Aspart polyurea coatings provide a robust barrier that prevents corrosion and extends the lifespan of these critical assets. The rapid curing time and strong adhesion properties of aspart polyurea make it an ideal choice for industrial anticorrosion applications, as it minimizes downtime and ensures long-lasting protection. In addition to oil and gas, other industries such as manufacturing and transportation also benefit from aspart polyurea's anticorrosion properties, as it is used to coat machinery, vehicles, and other metal components that are susceptible to rust and degradation. In building waterproofing applications, aspart polyurea is used to create seamless, impermeable membranes that protect structures from water infiltration. This is particularly important in areas with high rainfall or where buildings are exposed to moisture, such as basements, roofs, and foundations. Aspart polyurea's ability to adhere to various substrates, including concrete, wood, and metal, makes it versatile for different waterproofing needs. Its rapid curing time and flexibility allow for quick application and long-lasting protection, reducing the risk of water damage and associated repair costs. In addition to residential and commercial buildings, aspart polyurea is also used for waterproofing infrastructure projects, such as bridges, tunnels, and parking decks, where it provides a durable barrier against water and moisture. The construction of water containment structures, such as tanks and reservoirs, also benefits from aspart polyurea's waterproofing capabilities, ensuring that these structures remain leak-free and maintain their integrity over time. Beyond industrial anticorrosion and building waterproofing, aspart polyurea finds applications in a variety of other areas, driven by its unique properties and versatility. One such application is in the realm of flooring, where aspart polyurea is used to create durable, slip-resistant surfaces in industrial and commercial settings. Its resistance to chemicals, abrasion, and impact makes it ideal for use in warehouses, factories, and other high-traffic areas where floors are subject to heavy wear and tear. Aspart polyurea coatings can also be customized with different textures and colors, allowing for aesthetic flexibility in addition to functional benefits. Another emerging application of aspart polyurea is in the field of energy, where it is used to coat wind turbine blades and solar panels. The protective layer provided by aspart polyurea helps to enhance the durability and efficiency of these renewable energy technologies, contributing to their long-term performance and sustainability. Additionally, aspart polyurea is used in the manufacturing of protective gear and equipment, such as helmets and body armor, where its impact resistance and lightweight properties are highly valued. As industries continue to innovate and seek materials that offer superior performance and protection, the range of applications for aspart polyurea is likely to expand, further driving the growth of the Global Aspart Polyurea Market.

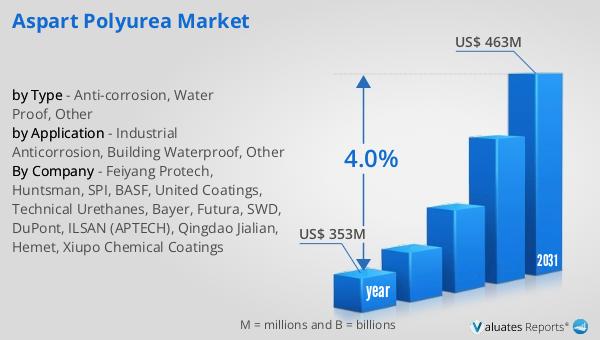

Global Aspart Polyurea Market Outlook:

The global market for Aspart Polyurea was valued at $353 million in 2024, and it is anticipated to grow to a revised size of $463 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.0% during the forecast period. This growth trajectory underscores the increasing demand for aspart polyurea coatings across various industries. The market's expansion is driven by the material's unique properties, such as rapid curing time, strong adhesion, and resistance to environmental factors, which make it an attractive choice for applications in construction, automotive, marine, and other sectors. As industries continue to prioritize durability and performance in their materials, the demand for aspart polyurea is expected to rise. The projected growth also highlights the potential for innovation and development within the market, as manufacturers seek to enhance the properties of aspart polyurea and expand its range of applications. This growth is further supported by advancements in application technologies, which enable more efficient and effective use of aspart polyurea coatings. As the market continues to evolve, it presents opportunities for companies to capitalize on the growing demand for high-performance coatings and contribute to the development of sustainable and durable solutions across various industries.

| Report Metric | Details |

| Report Name | Aspart Polyurea Market |

| Accounted market size in year | US$ 353 million |

| Forecasted market size in 2031 | US$ 463 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Feiyang Protech, Huntsman, SPI, BASF, United Coatings, Technical Urethanes, Bayer, Futura, SWD, DuPont, ILSAN (APTECH), Qingdao Jialian, Hemet, Xiupo Chemical Coatings |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |