What is Global Alloys for Power Generation Market?

The Global Alloys for Power Generation Market is a crucial segment within the broader energy sector, focusing on the development and application of specialized metal alloys that enhance the efficiency and durability of power generation systems. These alloys are engineered to withstand extreme temperatures, pressures, and corrosive environments typically encountered in power plants, including those utilizing fossil fuels, nuclear energy, and renewable sources. The market encompasses a wide range of materials, each tailored to specific applications, such as turbines, boilers, and heat exchangers. The demand for these alloys is driven by the ongoing need for reliable and efficient energy production, as well as the push towards cleaner and more sustainable power generation technologies. As global energy consumption continues to rise, the market for these advanced materials is expected to grow, supported by technological advancements and increasing investments in power infrastructure. The market's growth is also influenced by regulatory standards aimed at reducing emissions and improving energy efficiency, prompting power generation companies to adopt high-performance alloys that can meet these stringent requirements. Overall, the Global Alloys for Power Generation Market plays a vital role in supporting the transition to a more sustainable energy future.

Nickel Alloy, Stainless Steel, Titanium Alloy, Composite Metal, Other in the Global Alloys for Power Generation Market:

Nickel alloys are a cornerstone of the Global Alloys for Power Generation Market, known for their exceptional resistance to heat and corrosion, making them ideal for high-temperature applications such as gas turbines and nuclear reactors. These alloys maintain their strength and stability under extreme conditions, ensuring the reliability and longevity of power generation equipment. Stainless steel, another critical material, offers a balance of strength, corrosion resistance, and cost-effectiveness, making it a versatile choice for various components in power plants, including piping, heat exchangers, and structural elements. Its ability to withstand harsh environments without significant degradation is crucial for maintaining operational efficiency and safety. Titanium alloys, though more expensive, provide unmatched strength-to-weight ratios and corrosion resistance, particularly in seawater and other aggressive environments. This makes them suitable for specialized applications in offshore wind turbines and other renewable energy systems where weight and durability are critical factors. Composite metals, which combine different materials to enhance specific properties, are gaining traction in the market as they offer tailored solutions for complex power generation challenges. These composites can be engineered to provide superior thermal conductivity, electrical resistance, or mechanical strength, depending on the application. Other alloys, including those based on aluminum and copper, also play a role in the market, offering unique advantages such as lightweight and excellent electrical conductivity. These materials are often used in electrical components and transmission systems, where efficiency and reliability are paramount. The diversity of materials within the Global Alloys for Power Generation Market reflects the varied demands of the industry, with each alloy offering distinct benefits that cater to specific operational needs. As the market evolves, ongoing research and development efforts are expected to yield new alloy compositions and processing techniques that further enhance the performance and sustainability of power generation systems.

Industry, Business, Other in the Global Alloys for Power Generation Market:

The usage of Global Alloys for Power Generation Market spans across various sectors, including industry, business, and other areas, each benefiting from the unique properties of these advanced materials. In the industrial sector, alloys are integral to the construction and maintenance of power plants, where they are used in critical components such as turbines, boilers, and heat exchangers. The ability of these materials to withstand high temperatures and corrosive environments ensures the efficient and reliable operation of power generation facilities, reducing downtime and maintenance costs. In the business sector, companies involved in the manufacturing and supply of power generation equipment rely on these alloys to produce high-quality products that meet stringent regulatory standards and customer expectations. The use of advanced alloys allows these businesses to offer competitive solutions that enhance the performance and longevity of power systems, thereby strengthening their market position. Other areas, such as research and development, also benefit from the Global Alloys for Power Generation Market, as ongoing innovations in alloy compositions and processing techniques drive improvements in energy efficiency and sustainability. These advancements contribute to the development of next-generation power technologies, including renewable energy systems and advanced nuclear reactors, which are essential for meeting future energy demands. The versatility and performance of these alloys make them indispensable in the quest for cleaner and more efficient power generation solutions, supporting the global transition towards a more sustainable energy landscape.

Global Alloys for Power Generation Market Outlook:

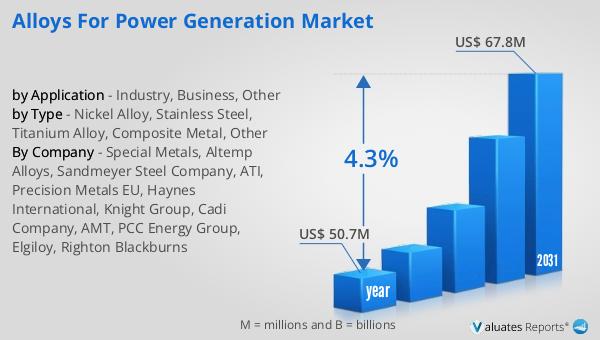

In 2024, the global market for Alloys for Power Generation was valued at approximately $50.7 million. This market is anticipated to experience growth over the coming years, with projections indicating that it will reach an estimated size of $67.8 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.3% during the forecast period. The expansion of this market is driven by several factors, including the increasing demand for efficient and durable materials in power generation systems, as well as the ongoing transition towards cleaner and more sustainable energy sources. As power generation technologies continue to evolve, the need for advanced alloys that can withstand extreme conditions and enhance system performance becomes increasingly critical. This market growth reflects the broader trends in the energy sector, where there is a strong emphasis on improving efficiency, reducing emissions, and ensuring the reliability of power generation infrastructure. The projected increase in market size underscores the importance of these materials in supporting the global energy transition and highlights the opportunities for innovation and investment in the development of new alloy compositions and applications.

| Report Metric | Details |

| Report Name | Alloys for Power Generation Market |

| Accounted market size in year | US$ 50.7 million |

| Forecasted market size in 2031 | US$ 67.8 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Special Metals, Altemp Alloys, Sandmeyer Steel Company, ATI, Precision Metals EU, Haynes International, Knight Group, Cadi Company, AMT, PCC Energy Group, Elgiloy, Righton Blackburns |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |