What is Global Mold Cavity Temperature Sensors Market?

The Global Mold Cavity Temperature Sensors Market is an essential segment within the broader industrial and manufacturing landscape. These sensors are crucial for monitoring and controlling the temperature within mold cavities during various manufacturing processes, such as injection molding and die casting. By providing precise temperature readings, these sensors help ensure the quality and consistency of the final products. They play a vital role in reducing defects, improving efficiency, and minimizing waste, which are critical factors in competitive manufacturing environments. The market for these sensors is driven by the increasing demand for high-quality, precision-engineered products across various industries, including automotive, electronics, and consumer goods. As manufacturers strive to enhance product quality and production efficiency, the adoption of advanced temperature sensing technologies is becoming more widespread. This market is characterized by continuous innovation, with companies investing in research and development to create more accurate, reliable, and durable sensors. The growth of this market is also supported by the rising trend of automation in manufacturing processes, where real-time data and precise control are paramount. Overall, the Global Mold Cavity Temperature Sensors Market is poised for significant growth as industries continue to prioritize quality and efficiency in their production processes.

Thermocouple, RTDs, Other in the Global Mold Cavity Temperature Sensors Market:

Thermocouples, RTDs (Resistance Temperature Detectors), and other types of temperature sensors are integral components of the Global Mold Cavity Temperature Sensors Market. Each of these sensor types has unique characteristics and applications, making them suitable for different manufacturing environments. Thermocouples are among the most commonly used temperature sensors due to their wide temperature range, durability, and cost-effectiveness. They work by measuring the voltage difference between two dissimilar metals, which changes with temperature. This makes them ideal for applications where rapid temperature changes occur, such as in injection molding processes. Thermocouples are known for their fast response times and ability to withstand harsh conditions, making them a popular choice in industrial settings. On the other hand, RTDs offer high accuracy and stability over a narrower temperature range compared to thermocouples. They operate based on the principle that the electrical resistance of a metal changes with temperature. RTDs are typically used in applications where precision is critical, such as in the production of high-quality electronic components. They provide consistent and reliable temperature readings, which are essential for maintaining tight tolerances in manufacturing processes. Other types of temperature sensors used in mold cavity applications include infrared sensors and thermistors. Infrared sensors measure temperature by detecting the infrared radiation emitted by an object, allowing for non-contact temperature measurement. This is particularly useful in situations where direct contact with the mold cavity is not possible or desirable. Thermistors, on the other hand, are temperature-sensitive resistors that offer high sensitivity and fast response times. They are often used in applications where small size and low cost are important considerations. The choice of sensor type depends on various factors, including the specific requirements of the manufacturing process, the desired level of accuracy, and the environmental conditions in which the sensors will be used. As the Global Mold Cavity Temperature Sensors Market continues to evolve, manufacturers are increasingly focusing on developing sensors that offer enhanced performance, reliability, and ease of integration into existing systems. This includes the development of smart sensors with advanced features such as wireless connectivity, real-time data analysis, and predictive maintenance capabilities. These innovations are helping manufacturers optimize their production processes, reduce downtime, and improve overall product quality. In summary, the Global Mold Cavity Temperature Sensors Market encompasses a diverse range of sensor technologies, each with its own advantages and applications. Thermocouples, RTDs, and other sensor types play a crucial role in ensuring the efficiency and quality of manufacturing processes across various industries. As technology continues to advance, the market is expected to see further growth and innovation, driven by the increasing demand for high-quality, precision-engineered products.

Injection Molding, Die Casting, Other in the Global Mold Cavity Temperature Sensors Market:

The usage of Global Mold Cavity Temperature Sensors Market in injection molding, die casting, and other manufacturing processes is pivotal for ensuring product quality and process efficiency. In injection molding, these sensors are used to monitor the temperature of the mold cavity, which is critical for producing parts with consistent dimensions and properties. By providing real-time temperature data, these sensors enable manufacturers to optimize the injection molding process, reducing cycle times and minimizing defects. This is particularly important in industries such as automotive and electronics, where precision and quality are paramount. The sensors help in maintaining the ideal temperature profile throughout the molding cycle, ensuring that the plastic material flows and solidifies correctly. This results in parts with superior surface finish, dimensional accuracy, and mechanical properties. In die casting, mold cavity temperature sensors play a similar role in monitoring and controlling the temperature of the mold. Die casting involves the injection of molten metal into a mold cavity, and precise temperature control is essential for producing high-quality castings. Temperature sensors help ensure that the mold is at the optimal temperature for metal flow and solidification, reducing the risk of defects such as porosity, shrinkage, and warping. By providing accurate temperature data, these sensors enable manufacturers to fine-tune the die casting process, improving the quality and consistency of the final products. This is particularly important in the production of complex metal components used in industries such as aerospace, automotive, and consumer electronics. In addition to injection molding and die casting, mold cavity temperature sensors are used in other manufacturing processes where temperature control is critical. This includes processes such as blow molding, compression molding, and extrusion. In blow molding, for example, temperature sensors help ensure that the plastic material is at the correct temperature for forming hollow parts such as bottles and containers. In compression molding, sensors monitor the temperature of the mold to ensure that the material cures properly, resulting in parts with the desired properties. In extrusion, temperature sensors are used to monitor the temperature of the die and the extruded material, ensuring consistent product quality. Overall, the use of mold cavity temperature sensors in these manufacturing processes helps improve product quality, reduce waste, and increase production efficiency. By providing real-time temperature data, these sensors enable manufacturers to optimize their processes, reduce cycle times, and minimize defects. This is particularly important in today's competitive manufacturing environment, where quality and efficiency are key drivers of success. As the Global Mold Cavity Temperature Sensors Market continues to grow, manufacturers are increasingly adopting advanced temperature sensing technologies to enhance their production processes and meet the demands of their customers.

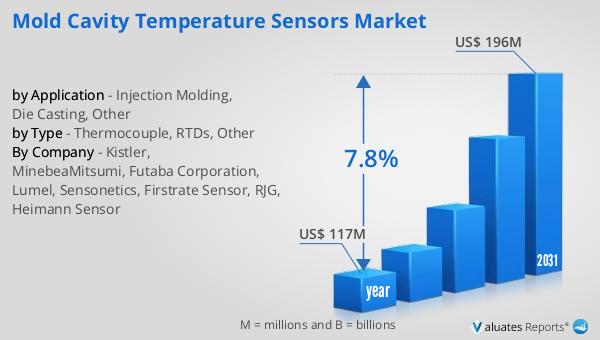

Global Mold Cavity Temperature Sensors Market Outlook:

The global market for Mold Cavity Temperature Sensors was valued at $117 million in 2024, with projections indicating it will expand to $196 million by 2031. This growth represents a compound annual growth rate (CAGR) of 7.8% over the forecast period. This upward trajectory underscores the increasing importance of temperature sensors in manufacturing processes, where precision and quality are critical. The demand for these sensors is driven by the need for high-quality, precision-engineered products across various industries, including automotive, electronics, and consumer goods. As manufacturers strive to enhance product quality and production efficiency, the adoption of advanced temperature sensing technologies is becoming more widespread. The market's growth is also supported by the rising trend of automation in manufacturing processes, where real-time data and precise control are paramount. Companies are investing in research and development to create more accurate, reliable, and durable sensors, further fueling market expansion. The increasing focus on reducing defects, improving efficiency, and minimizing waste in manufacturing processes is also contributing to the market's growth. As industries continue to prioritize quality and efficiency, the Global Mold Cavity Temperature Sensors Market is poised for significant growth in the coming years.

| Report Metric | Details |

| Report Name | Mold Cavity Temperature Sensors Market |

| Accounted market size in year | US$ 117 million |

| Forecasted market size in 2031 | US$ 196 million |

| CAGR | 7.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kistler, MinebeaMitsumi, Futaba Corporation, Lumel, Sensonetics, Firstrate Sensor, RJG, Heimann Sensor |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |