What is Global Mineral Analysis System Market?

The Global Mineral Analysis System Market is a dynamic and essential segment within the broader field of mineralogy and geosciences. This market encompasses a range of technologies and solutions designed to analyze and evaluate the composition and properties of minerals. These systems are crucial for various industries, including mining, construction, and environmental science, as they provide detailed insights into mineral content, structure, and quality. By utilizing advanced techniques such as spectroscopy, X-ray diffraction, and electron microscopy, these systems enable precise identification and quantification of minerals. This information is vital for making informed decisions regarding resource extraction, processing, and utilization. The market is driven by the increasing demand for efficient and accurate mineral analysis, which is essential for optimizing production processes and ensuring compliance with environmental regulations. As industries continue to seek sustainable and cost-effective solutions, the Global Mineral Analysis System Market is expected to grow, offering innovative tools and technologies to meet the evolving needs of its diverse clientele. The integration of digital technologies and automation further enhances the capabilities of these systems, making them indispensable in modern mineral analysis.

Portable, Desktop in the Global Mineral Analysis System Market:

The Global Mineral Analysis System Market is characterized by a variety of products, including portable and desktop systems, each catering to specific needs and applications. Portable mineral analysis systems are designed for field use, offering flexibility and convenience for on-site analysis. These systems are compact, lightweight, and equipped with advanced features that allow users to conduct real-time analysis of mineral samples. They are particularly useful in remote locations where immediate data is required to make critical decisions. Portable systems often employ techniques such as portable X-ray fluorescence (XRF) and near-infrared (NIR) spectroscopy, which provide rapid and accurate results. These systems are favored by geologists, mining engineers, and environmental scientists who require mobility and ease of use in challenging environments. On the other hand, desktop mineral analysis systems are typically used in laboratory settings, where more comprehensive and detailed analysis is required. These systems are equipped with sophisticated technologies such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and inductively coupled plasma mass spectrometry (ICP-MS). Desktop systems offer higher precision and are capable of analyzing a wider range of mineral properties, including crystallography, elemental composition, and isotopic ratios. They are essential for research institutions, universities, and large-scale mining operations that demand in-depth analysis and data accuracy. The choice between portable and desktop systems depends on the specific requirements of the user, including the level of detail needed, the environment in which the analysis is conducted, and the available budget. Both types of systems play a crucial role in the Global Mineral Analysis System Market, providing valuable insights that drive decision-making and innovation across various industries. As technology continues to advance, these systems are becoming more integrated, with features such as wireless connectivity, cloud-based data storage, and automated reporting, further enhancing their utility and efficiency. The ongoing development of new materials and techniques is also expanding the capabilities of mineral analysis systems, enabling them to address emerging challenges and opportunities in the field.

Mining, Coal, Geological Scientific Research, Others in the Global Mineral Analysis System Market:

The Global Mineral Analysis System Market finds extensive application across several key areas, including mining, coal, geological scientific research, and other sectors. In the mining industry, mineral analysis systems are indispensable tools for exploration and extraction processes. They provide critical data on mineral composition and quality, helping mining companies optimize their operations and maximize resource recovery. By accurately identifying valuable minerals and assessing their concentration, these systems enable more efficient extraction and processing, reducing waste and improving profitability. In the coal industry, mineral analysis systems are used to evaluate the quality and composition of coal deposits. This information is crucial for determining the suitability of coal for various applications, such as energy production and industrial processes. By analyzing factors such as ash content, sulfur levels, and calorific value, these systems help ensure that coal meets the required standards and specifications. Geological scientific research also relies heavily on mineral analysis systems to study the Earth's composition and history. Researchers use these systems to analyze rock and mineral samples, gaining insights into geological processes, mineral formation, and tectonic activity. This information is vital for advancing our understanding of the planet and informing environmental and conservation efforts. Beyond these primary areas, mineral analysis systems are also used in sectors such as construction, environmental monitoring, and material science. In construction, they help assess the suitability of raw materials for building projects, ensuring structural integrity and safety. In environmental monitoring, these systems are used to detect and analyze pollutants and contaminants in soil and water, supporting efforts to protect ecosystems and public health. In material science, mineral analysis systems contribute to the development of new materials and technologies by providing detailed information on mineral properties and interactions. Overall, the Global Mineral Analysis System Market plays a crucial role in supporting a wide range of industries and research fields, providing the data and insights needed to drive innovation and sustainability.

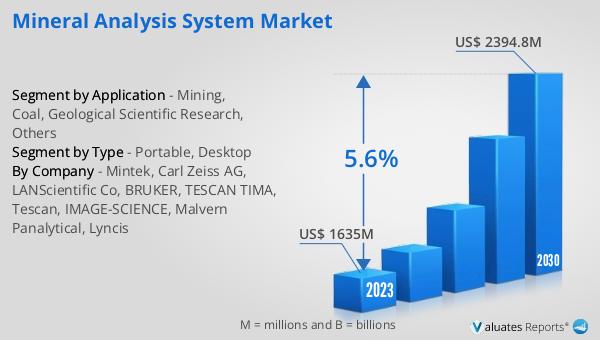

Global Mineral Analysis System Market Outlook:

The outlook for the Global Mineral Analysis System Market indicates a promising trajectory of growth and expansion. In 2024, the market was valued at approximately US$ 1814 million, reflecting its significant role in various industries that rely on mineral analysis for operational efficiency and strategic planning. Looking ahead, the market is projected to reach an estimated size of US$ 2642 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.6% during the forecast period. This upward trend underscores the increasing demand for advanced mineral analysis systems that offer precision, reliability, and efficiency. The market's expansion is driven by several factors, including technological advancements, the need for sustainable resource management, and the growing emphasis on environmental compliance. As industries continue to evolve and adapt to changing market dynamics, the demand for accurate and efficient mineral analysis solutions is expected to rise. This growth trajectory highlights the importance of mineral analysis systems in supporting industries such as mining, construction, and environmental science, where accurate data is crucial for decision-making and operational success. The integration of digital technologies and automation is also expected to play a significant role in shaping the future of the market, offering new opportunities for innovation and development.

| Report Metric | Details |

| Report Name | Mineral Analysis System Market |

| Accounted market size in year | US$ 1814 million |

| Forecasted market size in 2031 | US$ 2642 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Mintek, Carl Zeiss AG, LANScientific Co, BRUKER, TESCAN TIMA, Tescan, IMAGE-SCIENCE, Malvern Panalytical, Lyncis |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |