What is Global Construction HPMC Market?

The Global Construction Hydroxypropyl Methylcellulose (HPMC) Market is a specialized segment within the broader construction materials industry. HPMC is a non-ionic cellulose ether derived from natural sources, primarily used as an additive in construction applications. It plays a crucial role in enhancing the performance of construction materials by improving their workability, water retention, and adhesion properties. The market for construction HPMC is driven by the increasing demand for high-performance construction materials that can withstand diverse environmental conditions. As urbanization and infrastructure development continue to rise globally, the need for efficient and durable construction materials has become more pronounced. HPMC is particularly valued for its ability to improve the consistency and stability of construction mixtures, making it an essential component in products like cement, plaster, and adhesives. The market is characterized by a diverse range of applications, each requiring specific HPMC formulations to meet unique performance criteria. As a result, manufacturers are continually innovating to develop HPMC products that cater to the evolving needs of the construction industry, ensuring that they remain competitive in this dynamic market landscape.

Extra Low Viscosity, Low Viscosity, High Viscosity, Extra High Viscosity in the Global Construction HPMC Market:

In the Global Construction HPMC Market, viscosity is a critical factor that determines the suitability of HPMC for various applications. Viscosity refers to the thickness or flow characteristics of a liquid, and in the context of HPMC, it influences how the product behaves when mixed with other construction materials. Extra Low Viscosity HPMC is typically used in applications where a high degree of fluidity is required. This type of HPMC is ideal for self-leveling compounds and certain types of adhesives where ease of application and smooth spreading are crucial. Low Viscosity HPMC, on the other hand, is often used in applications that require a balance between fluidity and stability. It is commonly found in tile adhesives and joint fillers, where it helps to improve the workability and adhesion of the mixture without compromising its structural integrity. High Viscosity HPMC is preferred in applications that demand greater thickness and stability, such as in masonry mortars and gypsum-based plasters. This type of HPMC provides excellent water retention and enhances the cohesiveness of the mixture, ensuring that it adheres well to surfaces and maintains its form during drying. Extra High Viscosity HPMC is used in specialized applications where maximum thickness and stability are required. It is often employed in heavy-duty construction materials that need to withstand significant stress and environmental challenges. The choice of viscosity level in HPMC is crucial, as it directly impacts the performance and durability of the construction material in which it is used. Manufacturers must carefully select the appropriate viscosity level to ensure that their products meet the specific needs of their intended applications. This requires a deep understanding of the properties of HPMC and the demands of the construction industry, as well as ongoing research and development to innovate and improve HPMC formulations. As the construction industry continues to evolve, the demand for HPMC products with varying viscosity levels is expected to grow, driven by the need for more efficient and sustainable construction solutions.

Masonry Mortar, Joint Filler, Tile Adhesive, Gypsum Based Plaster, Others in the Global Construction HPMC Market:

The Global Construction HPMC Market finds extensive usage in various construction applications, each benefiting from the unique properties of HPMC. In masonry mortar, HPMC is used to enhance the workability and water retention of the mixture. This ensures that the mortar remains pliable and easy to apply, while also preventing premature drying and cracking. The improved adhesion properties of HPMC also help the mortar to bond more effectively with masonry units, resulting in a stronger and more durable structure. In joint fillers, HPMC plays a crucial role in improving the consistency and stability of the mixture. It helps to prevent sagging and shrinkage, ensuring that the joint filler remains in place and provides a smooth, even finish. The water retention properties of HPMC also help to prevent the joint filler from drying out too quickly, reducing the risk of cracking and ensuring a long-lasting seal. Tile adhesives benefit from the addition of HPMC by gaining improved workability and adhesion. HPMC helps to create a smooth, easy-to-apply adhesive that bonds tiles securely to surfaces, reducing the risk of tiles becoming loose or dislodged over time. The enhanced water retention properties of HPMC also help to prevent the adhesive from drying out too quickly, ensuring a strong and durable bond. In gypsum-based plasters, HPMC is used to improve the workability and consistency of the mixture. It helps to create a smooth, even plaster that is easy to apply and provides a high-quality finish. The water retention properties of HPMC also help to prevent the plaster from drying out too quickly, reducing the risk of cracking and ensuring a long-lasting finish. Other applications of HPMC in the construction industry include its use in self-leveling compounds, renders, and insulation materials. In each of these applications, HPMC helps to improve the performance and durability of the construction material, ensuring that it meets the specific needs of the project. As the construction industry continues to evolve, the demand for HPMC products is expected to grow, driven by the need for more efficient and sustainable construction solutions.

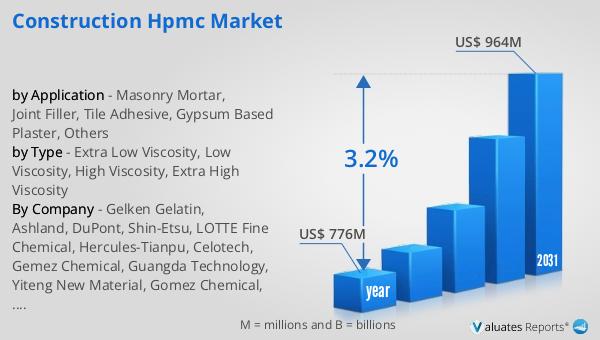

Global Construction HPMC Market Outlook:

The outlook for the Global Construction HPMC Market indicates a steady growth trajectory over the coming years. In 2024, the market was valued at approximately $776 million, reflecting its significant role in the construction industry. By 2031, projections suggest that the market will expand to a revised size of $964 million, driven by a compound annual growth rate (CAGR) of 3.2% during the forecast period. This growth is attributed to the increasing demand for high-performance construction materials that can enhance the durability and efficiency of construction projects. As urbanization and infrastructure development continue to accelerate globally, the need for advanced construction materials like HPMC is expected to rise. The market's expansion is also supported by ongoing research and development efforts aimed at improving the properties and applications of HPMC, ensuring that it remains a vital component in the construction industry. Manufacturers are continually innovating to develop HPMC products that cater to the evolving needs of the construction sector, ensuring that they remain competitive in this dynamic market landscape. The steady growth of the Global Construction HPMC Market underscores its importance in the construction industry and highlights the ongoing demand for efficient and sustainable construction solutions.

| Report Metric | Details |

| Report Name | Construction HPMC Market |

| Accounted market size in year | US$ 776 million |

| Forecasted market size in 2031 | US$ 964 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Gelken Gelatin, Ashland, DuPont, Shin-Etsu, LOTTE Fine Chemical, Hercules-Tianpu, Celotech, Gemez Chemical, Guangda Technology, Yiteng New Material, Gomez Chemical, Haoshuo Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |