What is Global Bio-Soluble Fiber Paper Market?

The Global Bio-Soluble Fiber Paper Market is an emerging segment within the broader industrial materials sector, focusing on the production and distribution of bio-soluble fiber paper. This type of paper is crafted from fibers that are soluble in biological environments, making them less harmful to human health and the environment compared to traditional refractory ceramic fibers. Bio-soluble fiber paper is primarily used for insulation purposes due to its excellent thermal resistance, lightweight nature, and flexibility. It is increasingly being adopted across various industries such as construction, aerospace, petrochemical, and automotive, where high-temperature insulation is crucial. The market is driven by the growing demand for eco-friendly and sustainable materials, as industries worldwide are under pressure to reduce their environmental footprint. Additionally, stringent regulations regarding workplace safety and environmental protection are pushing companies to adopt safer alternatives like bio-soluble fiber paper. As a result, the market is witnessing significant growth, with manufacturers investing in research and development to enhance the properties and applications of these fibers. The global reach of this market is expanding as more regions recognize the benefits of bio-soluble fiber paper, making it a key player in the future of industrial insulation materials.

1mm, 2mm, 3mm, Others in the Global Bio-Soluble Fiber Paper Market:

In the Global Bio-Soluble Fiber Paper Market, the thickness of the fiber paper plays a crucial role in determining its application and effectiveness. The market offers various thickness options, including 1mm, 2mm, 3mm, and other custom sizes, each catering to specific industrial needs. The 1mm bio-soluble fiber paper is typically used in applications where space is limited, and a thin layer of insulation is sufficient. Its lightweight and flexible nature make it ideal for use in small-scale projects or as a supplementary layer in more complex insulation systems. This thickness is often favored in the automotive industry, where it can be used to insulate components without adding significant weight or bulk. The 2mm bio-soluble fiber paper offers a balance between thickness and flexibility, making it suitable for a wider range of applications. It provides enhanced thermal resistance compared to the 1mm variant, making it a popular choice in the construction industry for insulating walls, roofs, and floors. Its ability to withstand higher temperatures without degrading makes it an excellent option for use in environments where heat exposure is a concern. Additionally, the 2mm thickness is often used in the aerospace industry, where materials must meet stringent safety and performance standards. The 3mm bio-soluble fiber paper is designed for heavy-duty applications where maximum insulation is required. Its increased thickness provides superior thermal resistance, making it ideal for use in high-temperature environments such as petrochemical plants and industrial furnaces. This thickness is also favored in the construction of fireproof barriers and protective linings, where its robust nature ensures long-lasting performance. The 3mm variant is often used in conjunction with other insulation materials to create multi-layered systems that offer enhanced protection against heat and fire. Beyond the standard thickness options, the Global Bio-Soluble Fiber Paper Market also caters to custom requirements, offering other sizes to meet specific industrial needs. These custom sizes are often used in specialized applications where standard thicknesses may not provide the desired level of insulation or flexibility. For example, in the automotive industry, custom-sized bio-soluble fiber paper can be used to insulate complex engine components or to create bespoke heat shields. Similarly, in the aerospace sector, custom sizes may be required to fit the unique contours of aircraft components, ensuring optimal insulation without compromising on weight or space. Overall, the availability of various thickness options in the Global Bio-Soluble Fiber Paper Market allows industries to select the most appropriate material for their specific needs. Whether it's the lightweight and flexible 1mm paper, the versatile 2mm option, the heavy-duty 3mm variant, or custom sizes, bio-soluble fiber paper provides a sustainable and effective solution for high-temperature insulation across a wide range of applications. As industries continue to prioritize safety, performance, and environmental sustainability, the demand for bio-soluble fiber paper in various thicknesses is expected to grow, driving further innovation and development in this dynamic market.

Construction, Aerospace, Petrochemical, Automotive, Others in the Global Bio-Soluble Fiber Paper Market:

The Global Bio-Soluble Fiber Paper Market finds extensive usage across several key industries, each benefiting from its unique properties and advantages. In the construction industry, bio-soluble fiber paper is primarily used for insulation purposes. Its excellent thermal resistance makes it an ideal choice for insulating walls, roofs, and floors, helping to maintain energy efficiency in buildings. Additionally, its lightweight and flexible nature allow for easy installation, reducing labor costs and time. The construction industry also benefits from the fire-resistant properties of bio-soluble fiber paper, which can be used to create fireproof barriers and protective linings, enhancing the safety of buildings. In the aerospace industry, bio-soluble fiber paper is used to insulate various components of aircraft, where weight and safety are critical considerations. Its lightweight nature ensures that it does not add significant weight to the aircraft, while its thermal resistance helps protect sensitive components from extreme temperatures. The flexibility of bio-soluble fiber paper allows it to be easily molded to fit the unique contours of aircraft parts, ensuring comprehensive insulation without compromising on performance. Additionally, the use of bio-soluble fiber paper in the aerospace industry aligns with the sector's increasing focus on sustainability and environmental responsibility. The petrochemical industry also relies heavily on bio-soluble fiber paper for insulation purposes. In this sector, the material is used to insulate pipes, tanks, and other equipment that operate at high temperatures. The superior thermal resistance of bio-soluble fiber paper ensures that it can withstand the extreme conditions often encountered in petrochemical plants, reducing the risk of heat-related damage and improving the efficiency of operations. Furthermore, the use of bio-soluble fiber paper in the petrochemical industry helps to enhance workplace safety by minimizing the risk of burns and other heat-related injuries. In the automotive industry, bio-soluble fiber paper is used to insulate various components of vehicles, including engines, exhaust systems, and heat shields. Its lightweight nature ensures that it does not add unnecessary weight to the vehicle, while its thermal resistance helps protect components from heat damage. The flexibility of bio-soluble fiber paper allows it to be easily integrated into the complex designs of modern vehicles, ensuring comprehensive insulation without compromising on performance. Additionally, the use of bio-soluble fiber paper in the automotive industry supports the sector's efforts to reduce emissions and improve fuel efficiency by maintaining optimal operating temperatures. Beyond these key industries, bio-soluble fiber paper is also used in a variety of other applications, including industrial furnaces, kilns, and ovens, where high-temperature insulation is required. Its versatility and effectiveness make it a valuable material for any application where heat resistance and safety are paramount. As industries continue to prioritize sustainability and environmental responsibility, the demand for bio-soluble fiber paper is expected to grow, driving further innovation and development in this dynamic market.

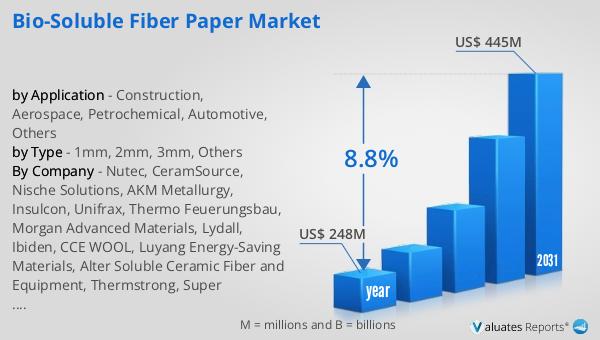

Global Bio-Soluble Fiber Paper Market Outlook:

The global market for Bio-Soluble Fiber Paper was valued at $248 million in 2024, and it is anticipated to expand significantly, reaching an estimated size of $445 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.8% over the forecast period. This impressive growth rate underscores the increasing demand for bio-soluble fiber paper across various industries, driven by its eco-friendly properties and superior performance in high-temperature insulation applications. The market's expansion is fueled by the growing awareness of the environmental and health benefits associated with bio-soluble fibers, as they offer a safer alternative to traditional refractory ceramic fibers. Industries such as construction, aerospace, petrochemical, and automotive are increasingly adopting bio-soluble fiber paper to enhance safety, improve energy efficiency, and reduce their environmental footprint. As regulations surrounding workplace safety and environmental protection become more stringent, the demand for bio-soluble fiber paper is expected to rise, further propelling market growth. Manufacturers are investing in research and development to enhance the properties and applications of bio-soluble fiber paper, ensuring that it remains a competitive and sustainable solution for high-temperature insulation needs. The global reach of this market is expanding as more regions recognize the benefits of bio-soluble fiber paper, making it a key player in the future of industrial insulation materials.

| Report Metric | Details |

| Report Name | Bio-Soluble Fiber Paper Market |

| Accounted market size in year | US$ 248 million |

| Forecasted market size in 2031 | US$ 445 million |

| CAGR | 8.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nutec, CeramSource, Nische Solutions, AKM Metallurgy, Insulcon, Unifrax, Thermo Feuerungsbau, Morgan Advanced Materials, Lydall, Ibiden, CCE WOOL, Luyang Energy-Saving Materials, Alter Soluble Ceramic Fiber and Equipment, Thermstrong, Super Refractory Ceramic Fiber |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |