What is Global Ring Gauge & Plug Gauge Market?

The Global Ring Gauge & Plug Gauge Market is a specialized segment within the broader industrial tools and equipment industry. These gauges are precision tools used to measure the dimensions of various components, ensuring they meet specific standards and tolerances. The market for these gauges is driven by the need for high precision in manufacturing processes across various industries. As industries continue to evolve and demand higher quality and precision, the need for reliable measurement tools like ring and plug gauges becomes increasingly critical. These tools are essential in maintaining quality control and ensuring that parts fit together correctly, which is vital in sectors such as automotive, aerospace, and machinery. The market is characterized by a mix of established players and new entrants, each striving to offer innovative solutions that meet the changing needs of their customers. With advancements in technology, there is a growing trend towards digital and automated measurement solutions, which is expected to influence the market dynamics in the coming years. The market's growth is also supported by the increasing globalization of manufacturing processes, which necessitates consistent quality standards across different regions.

Ring Gauge, Plug Gauge in the Global Ring Gauge & Plug Gauge Market:

Ring gauges and plug gauges are essential tools in the Global Ring Gauge & Plug Gauge Market, serving as critical components in the measurement and quality assurance processes across various industries. A ring gauge is a cylindrical tool used to check the external diameter of cylindrical objects, ensuring they conform to specified dimensions. It is typically made of hardened steel or carbide and is designed to provide a precise measurement by fitting over the part being measured. Ring gauges are often used in a "go/no-go" format, where one end of the gauge should fit over the part (go), and the other end should not (no-go), thus confirming the part's compliance with dimensional standards. On the other hand, a plug gauge is used to measure the internal diameter of holes or bores. Like ring gauges, plug gauges are also made from durable materials and are designed to provide accurate measurements. They are inserted into the hole or bore, and their fit determines whether the part meets the required specifications. Both ring and plug gauges are crucial in ensuring that parts fit together correctly, which is vital in industries where precision is paramount. In the automotive industry, for example, these gauges are used to ensure that engine components fit together seamlessly, reducing the risk of mechanical failure. In the aerospace industry, where safety is of utmost importance, ring and plug gauges help maintain the high standards required for aircraft components. The electrical and electronics industry also relies on these gauges to ensure that connectors and other components fit together correctly, preventing electrical failures. The machinery industry uses ring and plug gauges to maintain the precision of machine parts, ensuring that they operate efficiently and effectively. As industries continue to demand higher precision and quality, the role of ring and plug gauges in the manufacturing process becomes increasingly important. The market for these gauges is expected to grow as manufacturers seek to improve their quality control processes and meet the stringent standards required by their industries. With advancements in technology, there is also a growing trend towards digital and automated measurement solutions, which is expected to influence the market dynamics in the coming years.

Automobile, Electrical and Electronics, Aerospace, Machinery Industry, Others in the Global Ring Gauge & Plug Gauge Market:

The usage of ring gauges and plug gauges spans across various industries, each with its unique requirements and standards. In the automobile industry, these gauges are indispensable tools for ensuring that engine components and other critical parts fit together with precision. The automotive sector demands high levels of accuracy to ensure the safety and performance of vehicles. Ring and plug gauges help manufacturers maintain these standards by providing reliable measurements that confirm the dimensions of parts. This precision is crucial in preventing mechanical failures and ensuring the longevity of vehicles. In the electrical and electronics industry, ring and plug gauges are used to ensure that connectors, sockets, and other components fit together correctly. This is vital in preventing electrical failures and ensuring the reliability of electronic devices. The aerospace industry, known for its stringent safety standards, relies heavily on these gauges to maintain the precision of aircraft components. Any deviation from the specified dimensions can have serious implications for the safety and performance of aircraft. Ring and plug gauges help ensure that parts meet the required standards, reducing the risk of failure. In the machinery industry, these gauges are used to maintain the precision of machine parts, ensuring that they operate efficiently and effectively. The use of ring and plug gauges in these industries highlights their importance in maintaining quality control and ensuring that parts fit together correctly. As industries continue to evolve and demand higher precision, the role of these gauges in the manufacturing process becomes increasingly important. The market for ring and plug gauges is expected to grow as manufacturers seek to improve their quality control processes and meet the stringent standards required by their industries. With advancements in technology, there is also a growing trend towards digital and automated measurement solutions, which is expected to influence the market dynamics in the coming years.

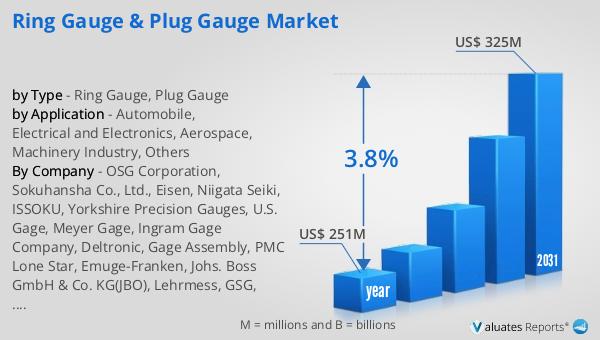

Global Ring Gauge & Plug Gauge Market Outlook:

The global market for ring gauges and plug gauges was valued at $251 million in 2024 and is anticipated to expand to a revised size of $325 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.8% over the forecast period. Europe emerges as a significant player in this market, holding over 30% of the global market share, followed by North America, which accounts for more than 20%. The automotive industry stands out as the largest application sector, representing nearly 40% of the market. This growth trajectory underscores the increasing demand for precision measurement tools across various industries. The automotive sector's dominance highlights the critical role these gauges play in ensuring the precision and reliability of vehicle components. As the market continues to evolve, the focus on quality control and precision measurement is expected to drive further advancements in gauge technology. The geographical distribution of market share indicates a strong presence in developed regions, where manufacturing processes demand high levels of accuracy and quality assurance. This trend is likely to continue as industries worldwide strive to meet stringent quality standards and enhance their manufacturing capabilities.

| Report Metric | Details |

| Report Name | Ring Gauge & Plug Gauge Market |

| Accounted market size in year | US$ 251 million |

| Forecasted market size in 2031 | US$ 325 million |

| CAGR | 3.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | OSG Corporation, Sokuhansha Co., Ltd., Eisen, Niigata Seiki, ISSOKU, Yorkshire Precision Gauges, U.S. Gage, Meyer Gage, Ingram Gage Company, Deltronic, Gage Assembly, PMC Lone Star, Emuge-Franken, Johs. Boss GmbH & Co. KG(JBO), Lehrmess, GSG, China Chengliang, BAKER |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |